CHINA NBC-YX-4030ZD automatic two-dimensional imaging instrument, workpiece crazing detection 400 × 300mm

SE

-

IPRE SC3020 one-button image Measurement Instrument, measuring range 300mm$ 16721.00SE

IPRE SC3020 one-button image Measurement Instrument, measuring range 300mm$ 16721.00SE -

IPRE SC1813 One-button fast imager, measuring range 180mm$ 14567.00SE

IPRE SC1813 One-button fast imager, measuring range 180mm$ 14567.00SE -

IPRE SC1008 One-button fast imager, measuring range 100mm$ 13100.00SE

IPRE SC1008 One-button fast imager, measuring range 100mm$ 13100.00SE -

IPRE XY5040Q image Measurement Instrument, travel 500mm$ 11239.00SE

IPRE XY5040Q image Measurement Instrument, travel 500mm$ 11239.00SE -

IPRE XY4030Q image Measurement Instrument, stroke 400mm$ 9868.00SE

IPRE XY4030Q image Measurement Instrument, stroke 400mm$ 9868.00SE

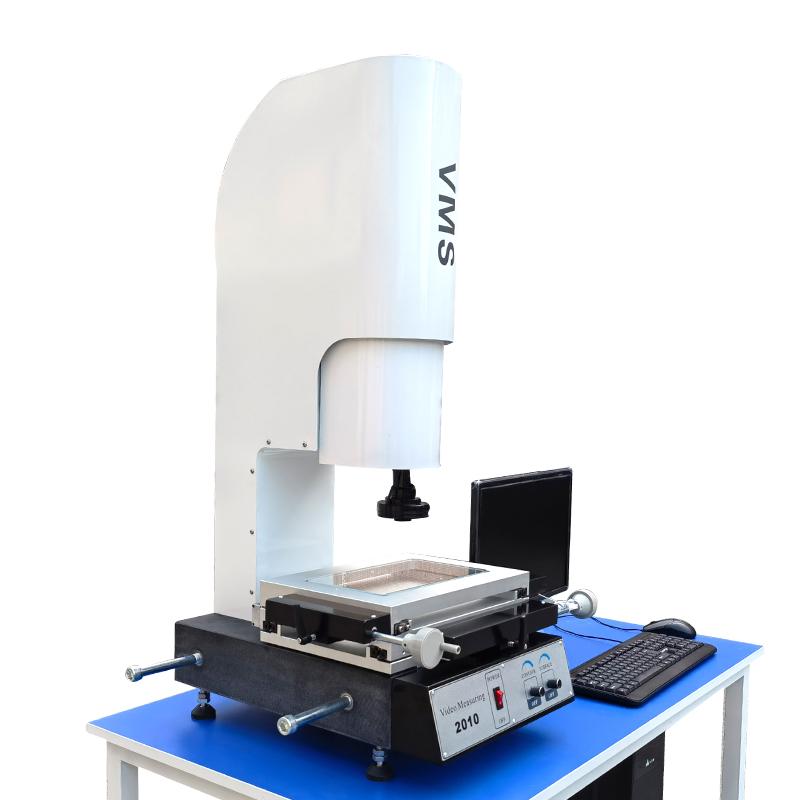

Factory NBC-YX-4030ZD Automatic imagerSPEC

Factory NBC-YX-4030ZD Automatic imagerDetails

Factory NBC-YX-4030ZD Automatic imagerPacking list

- SKU

- NB044697

- X/Y itinerary

- 400×300mm

- Z-axis lift

- 150mm

- Glass table

- 460×360mm

- Product Structure

- Base, column, mobile workbench are made of high-precision granite

- lighting system

- Light source and transmission Light source with LED, adjustable luminance

- CCD camera

- 1/3 high-definition color CCD camera (Miscellaneous brand can also be selected as required)

- magnification

- Step Zoom Optical inspection magnification: 0.7~ 4.5X, image magnification: 30~225X

- Measurement Accuracy

- (3+L/200)μm

- resolution

- 0.001mm

- Repeatability

- 0.002mm

- Operation mode

- Computer automatic control stroke

- Power

- 220V(AC) / 50HZ

- Recommended environment

- Temperature: 19~ 24 ℃, Humidity: 45%~ 75%

- Optional accessories

- Z-axis image altimetry or optional British Reishaw probe contact measurement

Introduction

The two-dimensional image measuring instrument uses a digital measurement method to convert the shape of the measured object into a computer through image acquisition, and uses professional measurement software to measure the size of the object, while traditional projectors amplify the object through optical projection for measurement;

The two-dimensional image measuring instrument is mainly used for the detection, positioning, evaluation and diagnosis of various defects inside the workpiece (welding seams, cracks, inclusions, pores, etc.). It can be used in laboratories and engineering sites . Widely used in boilers, pressure vessels, aerospace, aviation, electric power, petroleum, chemical industry, offshore oil, pipelines, military industry, shipbuilding, automobiles, machinery manufacturing, metallurgy, metal processing industry, steel structures, railway transportation, nuclear power, universities, etc. industry.

Features

1. Strive for high-precision measurement in the optical field and independently develop all-marble structural products (base, columns, and worktables are all made of high-precision "Jinan Qing" Chuntian

Natural granite, two-layer design, precision-grade V-shaped guide rails, giving the product extremely high stability and rigidity). This granite has stable chemical properties, is not easily weathered, can resist the erosion of acids, alkalis and corrosive gases, and will not deform. ,stainless;

2. Strengthen product structure and appearance design, pay attention to the practicality and stability of product software functions, provide profit promotions and feedback profits to friends from all walks of life, and strive for cost-effective products to make your choice more confident!

3. Three-axis friction precision transmission is sensitive and reliable, has no backlash and can move quickly;

4. High-quality optical system and high-resolution CCD can ensure clear measurement pictures;

5. Adjustable LED ring-shaped surface light source to achieve large-angle lighting and avoid heat deformation of the workpiece;

6. A digital element measurement and data processing system is composed of a precision optical ruler and a data processor.

NBC-YX-4030ZD

NBC-YX-4030ZD