China TBJ-X3-DJ14 Multifunctional Automatic Feeding Film Applicator Drawdown blade Heated

SE

-

TM3300 Wire bar & Drawdown Blade Laboratory Film Applicator with Heated Vacuum Table$ 4770.00SE

TM3300 Wire bar & Drawdown Blade Laboratory Film Applicator with Heated Vacuum Table$ 4770.00SE -

HUINUO TM3300pro High-precision Automatic Film Applicator with Drawdown Blade and Rod Applicator, Plus Heated Vacuum Table$ 5710.00SE

HUINUO TM3300pro High-precision Automatic Film Applicator with Drawdown Blade and Rod Applicator, Plus Heated Vacuum Table$ 5710.00SE -

HUINUO TM3300pro+ High-precision Rod & Drawdown Blade Coater with Heated Vacuum Table$ 6180.00SE

HUINUO TM3300pro+ High-precision Rod & Drawdown Blade Coater with Heated Vacuum Table$ 6180.00SE -

China NBC-X4-DJ7 Floor Type Automatic Film Applicator Effective film area 700 * 1300mm$ 21216.00SE

China NBC-X4-DJ7 Floor Type Automatic Film Applicator Effective film area 700 * 1300mm$ 21216.00SE -

CHINA Removable metering rod & drawdown blade heating vacuum adsorption laboratory Film Applicator TBJ-X3-DJ11C$ 4457.00SE

CHINA Removable metering rod & drawdown blade heating vacuum adsorption laboratory Film Applicator TBJ-X3-DJ11C$ 4457.00SE

zy TBJ-X3-DJ14 Automatic Film ApplicatorSPEC

zy TBJ-X3-DJ14 Automatic Film ApplicatorDetails

zy TBJ-X3-DJ14 Automatic Film ApplicatorPacking list

- SKU

- NB044967

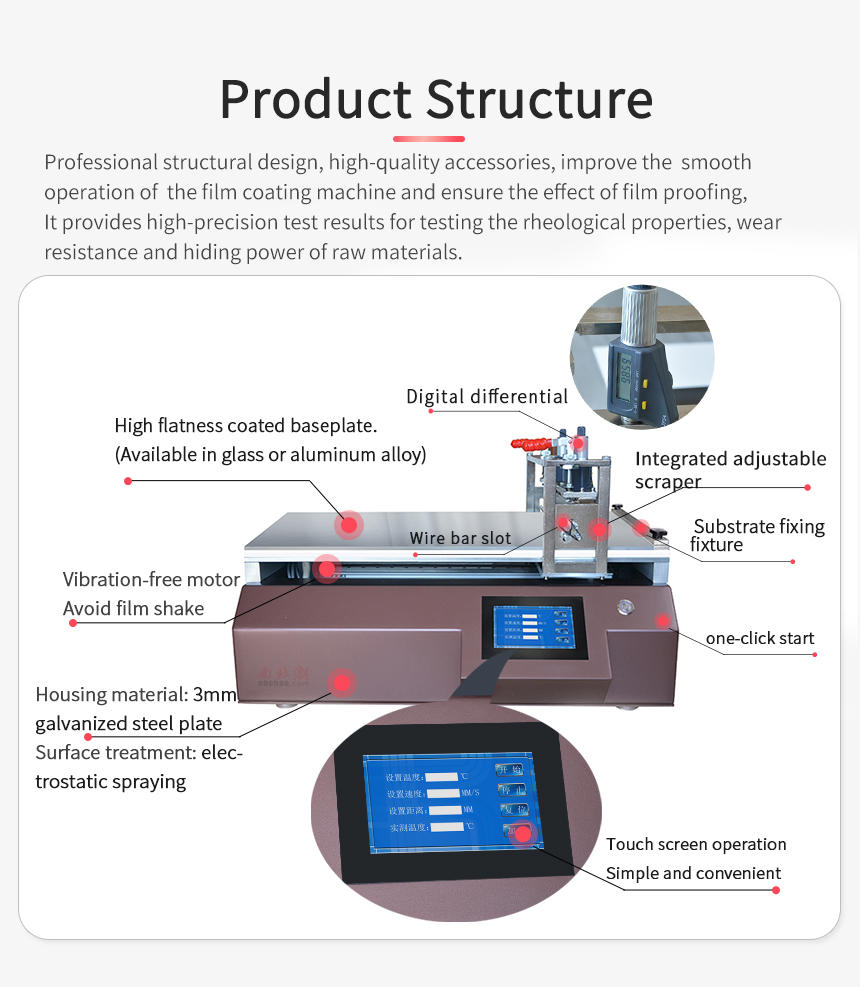

- Drawdown blade Accuracy

- ±0.003mm

- Drawdown blade film thickness

- 0~10Mm drawdown blade can be lifted

- Coating speed

- 5~ 180Mm/s (< 5mm/s can be customized)

- Coating size

- 300*400mm

- Drawdown blade heating temperature

- Room temperature~ 150 ℃

- Vacuum Area

- 300 * 400Mm (can be customized)

- Vacuum aperture

- Φ1.2mm

- Vacuum hole spacing

- 20*20mm

- Vacuum pump size

- 380*180*280mm

- Coating rod specification

- Accuracy 0.001mm (Spreader thickness is determined according to the rod model)

- Host Power

- 220V 50Hz

- Weight

- Net Weight 65KG

- speed control

- Infinitely variable speed

- Coating table material

- aluminum alloy

- Spreader Accuracy

- 0.001mm

- customization function

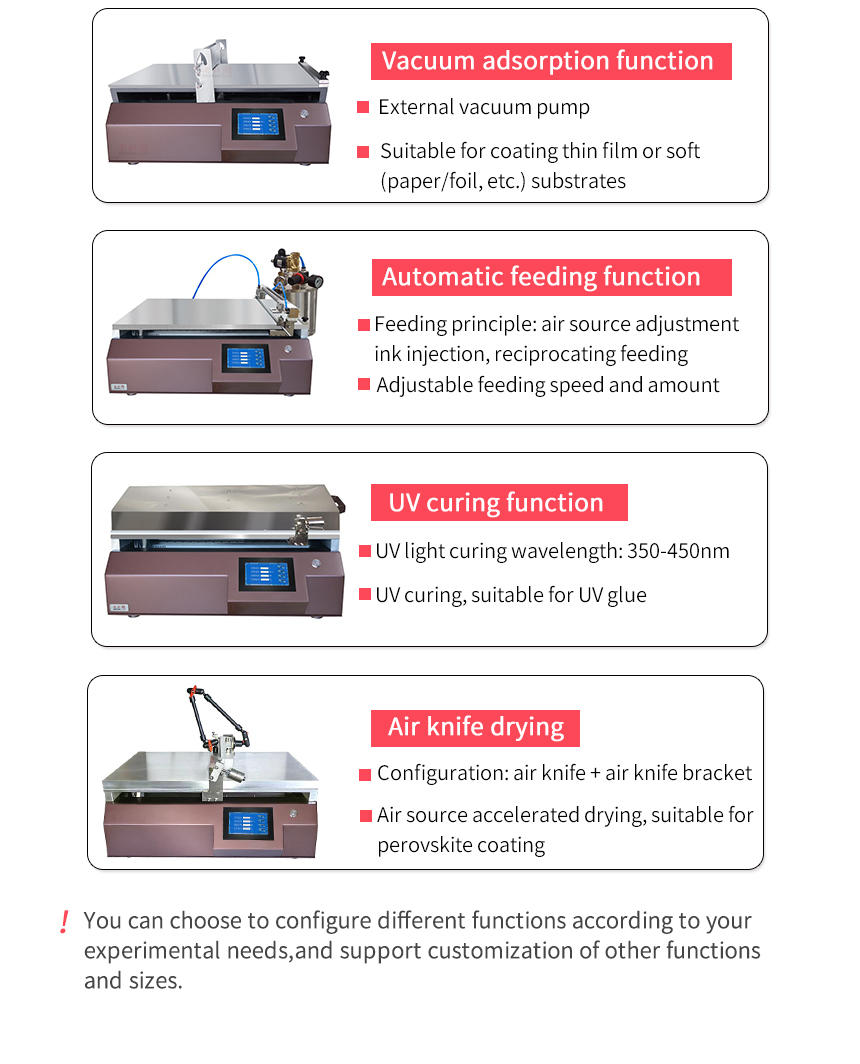

- Automatic feeding system

- Dimensions

- 630*410*520mm

- Feeding principle

- Air source pressure flows out

- Feed Sport Mode

- Reciprocating linear motion

- Feeding back and forth traverse speed

- 2-150mm/s

- spit Volume

- Adjustable (by adjusting the air pressure and the operating speed of the discharge port)

- Shaft drive mode

- Timer belt

- Feeding system air source

- 0.6Mpa, can be connected to the trachea of φ 8 (self-matching)

- Power Voltage of feeding system

- 220V,50Hz

- Tank pressure

- Maximum withstand 8Mpa

- Material of feeding barrel

- 304 stainless steel with a wall thickness of 4mm

- Feeding drum configuration

- Safety valve, pressure regulating valve, pressure gauge, relief valve

- Heating Temperature range

- RT+~180℃

- Temperature Uniformity

- ±3℃

- Feeding drum Volume

- 1L

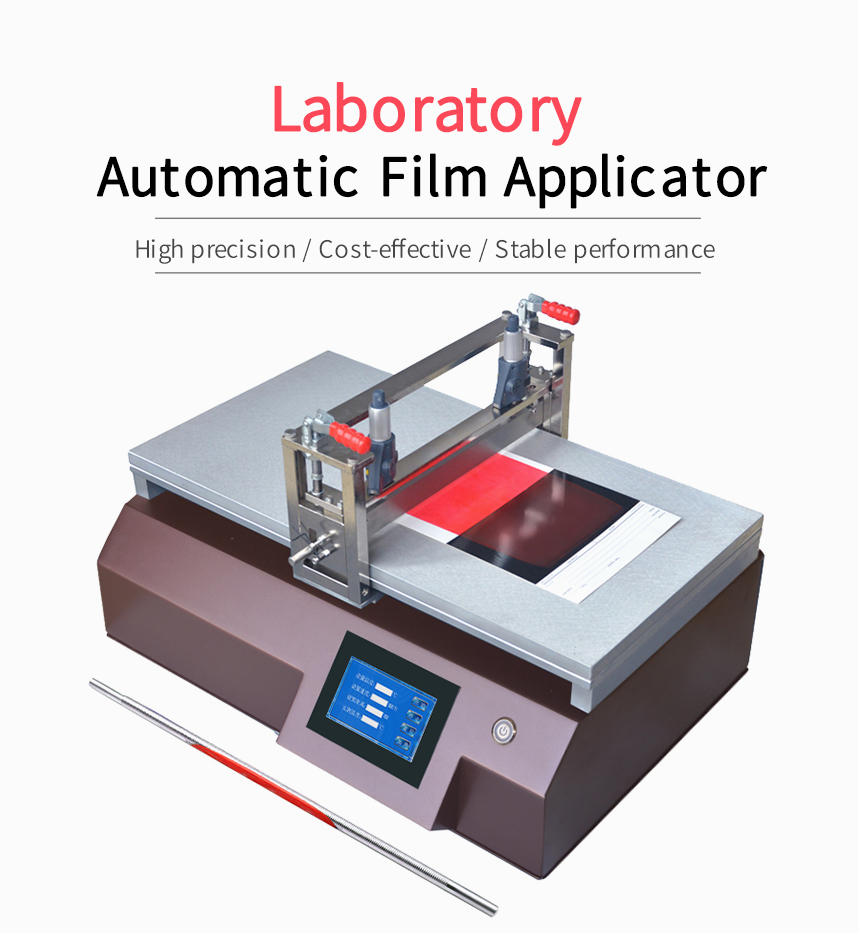

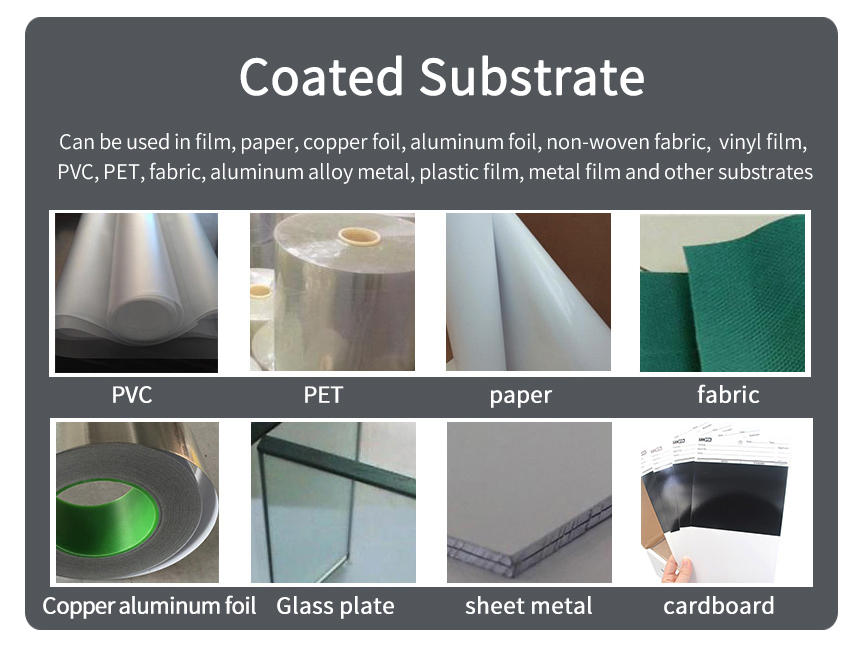

TBJ-X3-DJ14 four-in-one coating machine is an automatic feeding laboratory multi-functional coating machine, equipped with a heated scraper, heating temperature: room temperature~ 150 ℃, coating size 300 * 400mm.

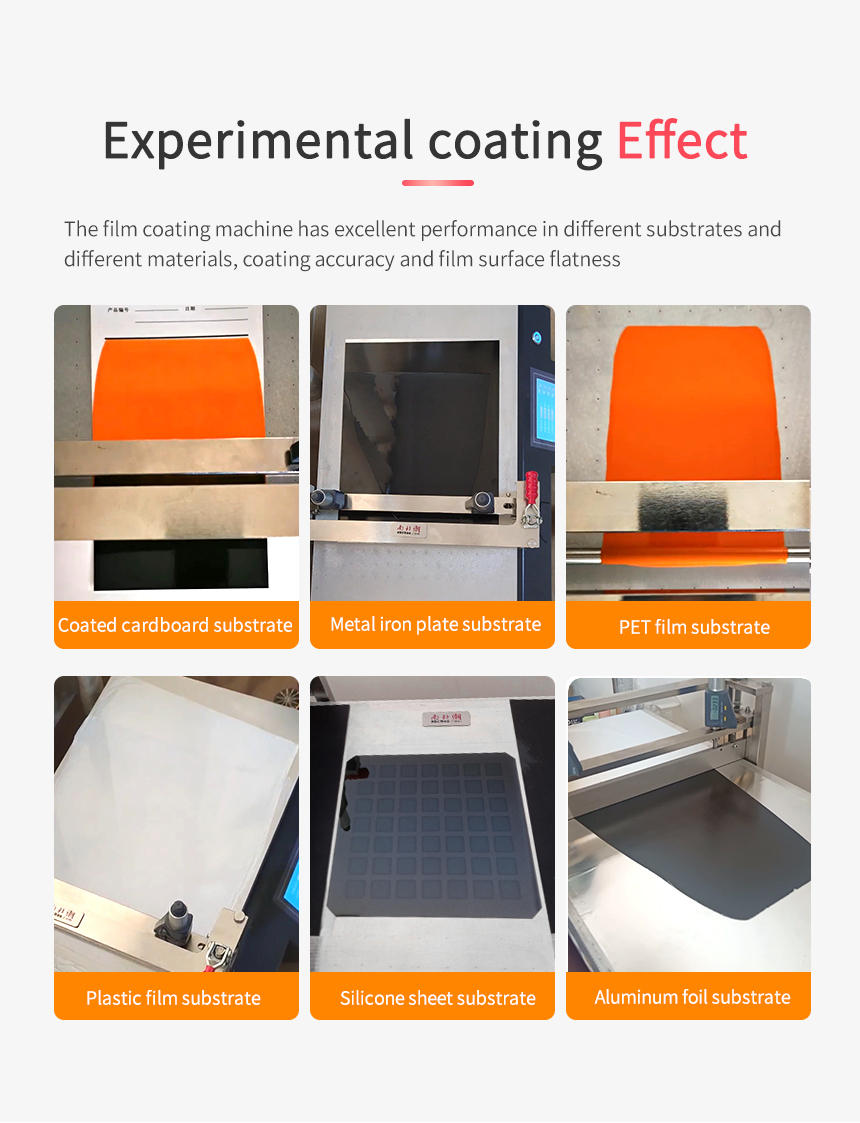

TBJ-X experimental small coating testing machine uses all imported accessories, and the price is cheap, which has been favored by many multinational R & D institutions, many familiar universities and scientific research institutions at home and abroad. By controlling the speed and stable pressure, the coating effect is guaranteed, and the uniformity and smoothness of the coating and coating are guaranteed.

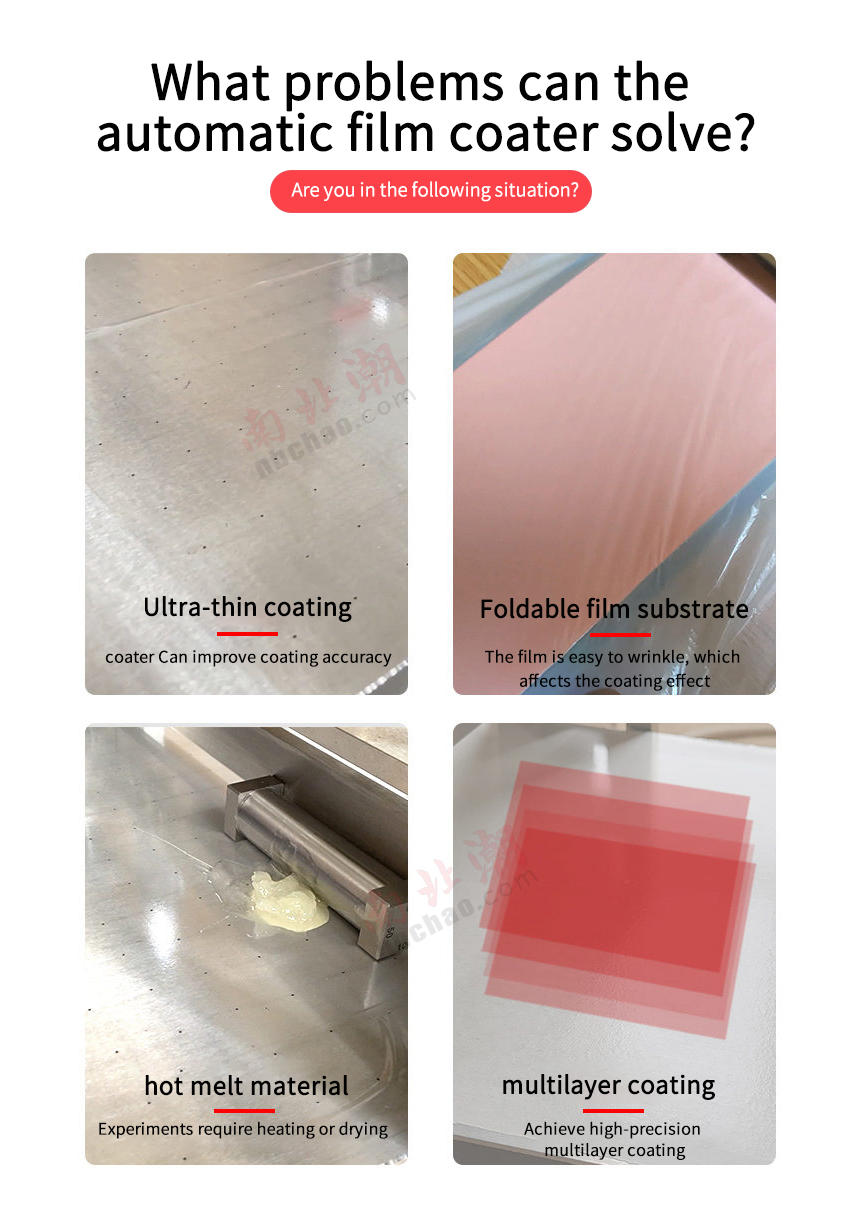

Since the main factors affecting the coating film are the coating speed and the pressure applied to the Film Applicator, the coating produced by manual coating often appears inconsistent, especially the difference between different people is even greater, which makes it difficult to compare the test results between samples. Our company's automatic Film Applicator is carefully designed to enable the operator to easily apply accurate wet films on different substrates, greatly improving the reproducibility of the coating film.

Optional

- 1Application of Vacuum adsorption Spreader Technique in Preparative Fluorescence Film on Release Membrane

- 2Brief analysis of the preparation technology of ionic liquid polymer composite electrolysis and anode pole piece

- 3Application of Film Applicator in Reticulated Lacquer film

- 4Film Applicator for amide film

- 5What are the functions of Perovskite Film Applicators?

- 6Application of coating bar in automatic film machine

- 7NBchao Film Applicator for Thermal Paper Preparative Adhesive

- 8Lab Film Applicator Application of Fluorescence Agent on Ceramic Silicon Wafers [Video Demonstration]

NBCHAO

- 9Experimental Demonstration of Automatic Film Applicator Coating High Viscosity Silica Gel on Nonwoven Fabrics

- 10Application of Lab Film Applicator to Lubricating Material on Aramid Fiber Cloth [Video Demonstration]

TBJ-X3-DJ14

TBJ-X3-DJ14