JINPUTE JPT-2023 Intelligent Ink Proofer Double Station Discharge

SE

JinPuTe JPT-2023 Intelligent Ink ProoferSPEC

JinPuTe JPT-2023 Intelligent Ink ProoferDetails

JinPuTe JPT-2023 Intelligent Ink ProoferPacking list

- SKU

- NB045118

- Voltage

- 220V +/- 10% (foreign 110V +/- 10% + conversion plug)

- Rotation speed

- 300 rpm (allow reset +)

- Swirl/spin specified number of turns

- 1/2 or can be set arbitrarily

- Swirling/spinning Accuracy

- 0.1 ° (degrees)

- LCD content

- Rotation speed, lap accumulation and other technical indicators

- Host Weight

- About 150Kg (export standard wooden box)

- Embossing roller

- Standard EPDM (silicone roller/polyurethane, etc./optional), hardness 75 ° (universal hardness of rubber roller selected by printing factory)

- Proofer packing size

- 750x600x500mm

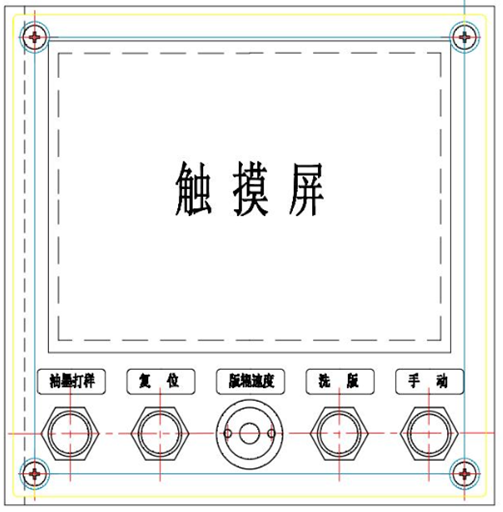

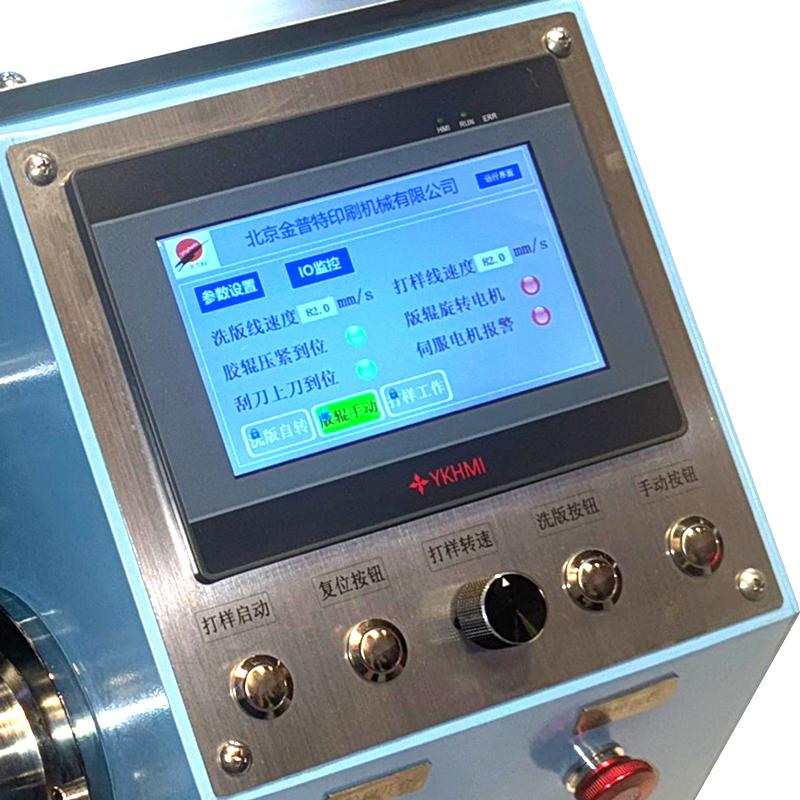

- Panel function settings

- emergency stop, proofing speed gear adjustable, plate roller cleaning, manual, reset, rubber roller opening and closing button

Introduction

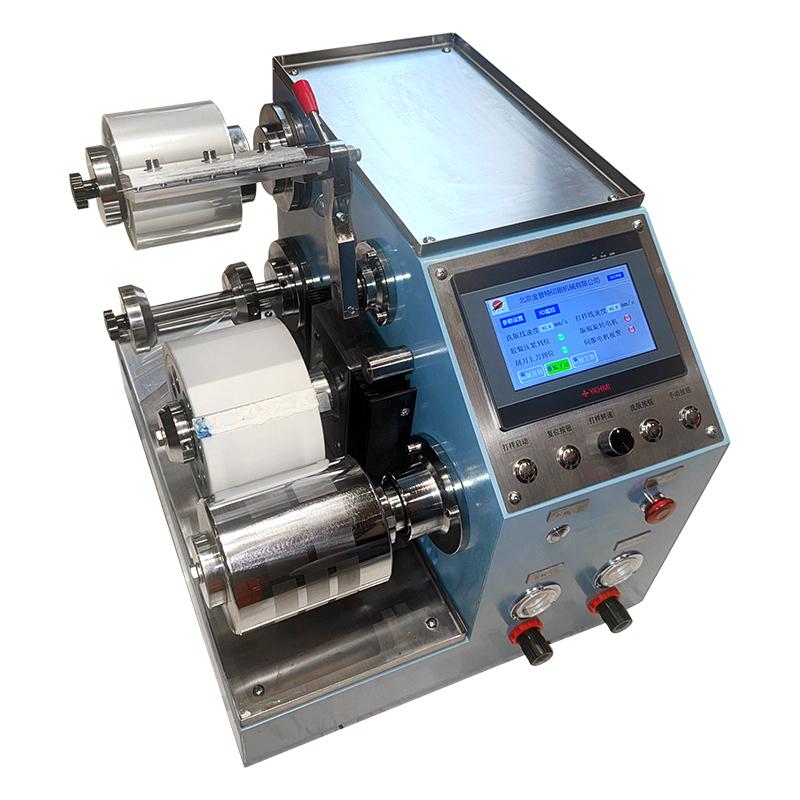

The intelligent proofing machine adopts fully intelligent LCD display, servo CNC motor drive, servo control system integrated structure, and synchronous belt driven plate roller spindle mechanism. All control parameters and measurement data can be displayed and adjusted in real time on the LCD, and It has functions such as reliable and precise repeat positioning.

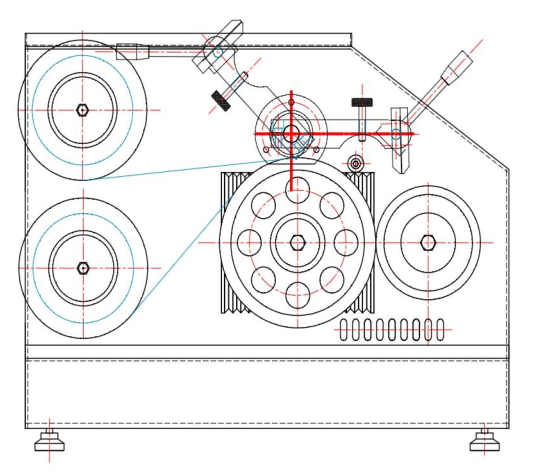

Appearance structure diagram

Operating Conditions of the proofing machine

1. Within the room temperature range of 10℃-35℃, the Relative Humidity should not be greater than 80%.

2. Install correctly and check the level on a stable foundation or workbench.

3. Use in a vibration-free environment.

4. There is no corrosive medium around.

5. The fluctuation range of the 220V power supply Voltage should not exceed ±10% of the rated Voltage.

6. The power supply needs to have strict grounding protection.

Agency presentation

The intelligent proofing machine consists of a host computer, an electrical controller and accessories. See the attached figure for details.

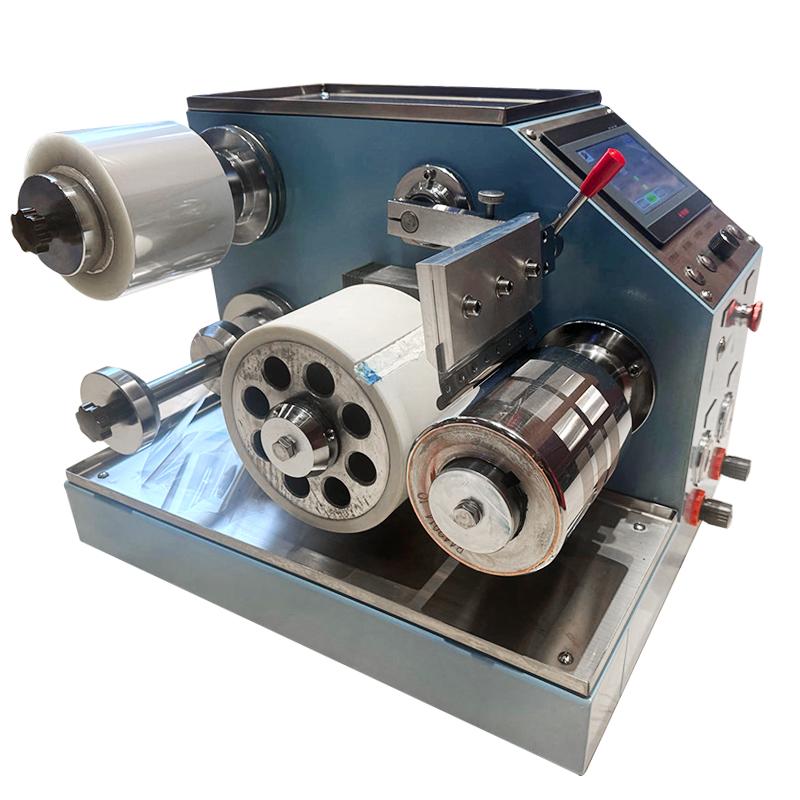

1. Host part

The main machine is divided into five parts: double unwinding part, pressure roller part, ink scraping part, plate roller part , and exhaust gas centralized storage and emission part.

A. The unwinding part uses a combination of friction plates and springs to form an effective constant tension, thereby ensuring that the unwinding tension can be adjusted and maintained.

B. The pressure roller part adopts silicone rubber roller, which effectively extends the life of the rubber roller.

C. The scraper part adopts a combination of aluminum alloy splint, Swiss imported combination knife holder, and Swiss ZOC-LL long-life small gold knife, which reduces the loss of the scraper and improves the convenience .

D. The plate roller part adopts customized high-precision plate rollers (made by Shangyun Plate Making Company) and professional layout design, which highlights the professional level and craftsmanship of the company.

E. The exhaust gas centralized storage part (optional) uses a high-speed fan to effectively store and discharge the solvent during proofing, and can be connected to the exhaust pipe.

2. Electrical control part

The electrical part of the intelligent proofing machine adopts a CNC servo-control integrated machine and a servo CNC motor to form a system with high speed, large torque and high rotation accuracy.

- 1Application of Manual Ink Proofer

- 2Printing ink suitability and paper surface strength

- 3Preparation of plastic water-based gravure ink by ink proofer

孙伟 - 《北京化工大学》

- 4Preparation of fluorescent anti-counterfeiting gravure ink with ink proofing machine

向华,龚逸仙,李军,林木雄,欧建志 - 《《用于塑料薄膜的荧光凹印油墨的制备与性能研究》》

- 1CY/T 104.2-2014《Graphic technology. Test methods for printability of paper and board. Part 2: Basic requirements on printabifity tester》

- 2CY/T 104.1-2014《Graphic technology. Test methods for printability of paper and board. Part 1:Terms》

- 3QB/T 1020-2018《Standard inks for testing printability of paper and board》

- 4CY/T 104.9-2014《Graphic technology- -Test methods for printability of paper and board -Part 9: Missing dot of recess (gravure) printing》

- 5CY/T 104.7-2014《Printing technology paper and board test methods for printability part 7: roughness of printing》

- 6CY/T 104.8-2014《Printing technical paper and board printability test method part 8: set-off》

- 7CY/T 104.6-2014《Printing technology paper and board printability test method part 6: print through》

- 8CY/T 104.4-2014《Graphic technology-Test methods for printability of paper and board Part 4: Printing uniformity》

- 9CY/T 104.3-2014《Printing technical paper and paperboard - Test methods for printability - Part 3: Printing permeability》

- 10CY/T 104.5-2014《Printing technology paper and board printability test methods part 5: ink transfer》

JPT-2023

JPT-2023