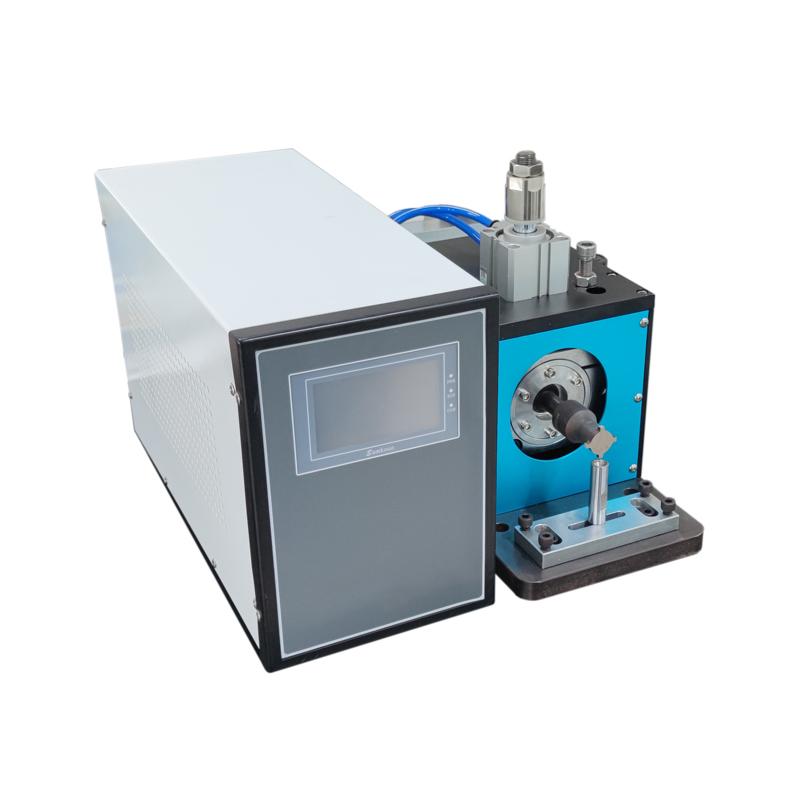

CHINA NBC-UWL11A Ultrasonic metal spot welding machine 40KHz

SE

Factory NBC-UWL11A(40K) Ultrasonic metal spot welding machineSPEC

Factory NBC-UWL11A(40K) Ultrasonic metal spot welding machineDetails

Factory NBC-UWL11A(40K) Ultrasonic metal spot welding machinePacking list

- SKU

- NB045132

- application

- General purpose for welding copper and aluminum

- Operating Voltage

- AC220V/50Hz

- Operating Pressure

- 0.5~0.7Mpa

- Ultrasonic Frequency

- 40KHz

- Power

- 800W

- welding time

- 0~1S

- solder layer

- Within 20 floors

- Drive form

- Pneumatic

- Device Weight

- About 60Kg

- Control box size

- L450×W200×H280mm

- Generator size

- L350×W280×H350mm

Introduction

Ultrasonic metal spot welding machine is generally used for metal welding in coiling and lamination processes. It has the characteristics of small size, beautiful appearance, easy operation, solid structure, stable and safe use.

Principle

The principle of ultrasonic high-frequency vibration friction is used to convert the energy of ultrasonic vibration into friction energy and transmit it to the metal surface to be welded. When friction generates heat and applies pressure to it, the metal structure molecules are fully activated to form between molecular layers. Fusion of new equipment.

main feature

Touch screen interface, intuitive and convenient, with automatic frequency tracking.

There are no traces of oxidation. Ultrasonic waves have a cleaning function. Even if there are contaminants or oxides on the metal surface, it can be welded well without surface treatment.

All workpieces do not need to be pre-processed and can be welded without soldering tin or soldering oil additives, which is economical and convenient.

The welding head is made of wear-resistant materials for long-lasting durability.

The internal resistance of the solder joint is small. After welding, the conductivity is good, and its resistivity is extremely low, close to zero.

The welding time is very short, and welding can generally be completed instantly within 0.01-2 seconds.

The solder joints are firm, the working temperature does not exceed its annealing temperature, and the metallographic structure of the workpiece is not changed. Its melting strength is stronger than other welding methods, and the welding interface is neat and clean.

Welding has low cost, fast speed, easy operation and convenient maintenance.

No sparks are produced during welding, so the operator is safe and secure. There is no smoke smell and no air pollution.

Applicable welding range

*Battery pole pieces: single point, multi-point, single layer, multi-layer, nickel strip + copper foil, nickel strip + aluminum strip, aluminum strip + aluminum foil, aluminum strip + aluminum cover, aluminum shell + aluminum-nickel composite strip and other materials Welding of square, strip and other processes.

*Welding of automobile wiring terminals, automobile wiring harness, motor terminals, relay sheets, electrolysis, capacitor pole pieces, carbon brush sheets, heat sink sheets, copper tubes, copper tubes + aluminum sheets, copper tubes + copper sheets and other processes.

Weldable materials

1: 0.2mm nickel bar + 120 layers of copper foil battery core negative electrode multi-point welding;

2: 0.2mm aluminum strip + 120 layers of aluminum foil battery positive electrode multi-point welding;

3.: 0.2mm copper nickel plating + 120 layers copper foil battery core negative electrode spot welding

Welding process

Aluminum strip and aluminum cover welding; Nickel strip and copper foil welding (multi-point); Aluminum strip and aluminum foil welding (strip); Aluminum strip and aluminum foil welding (strip); Aluminum strip and aluminum foil welding (multi-point); Nickel strip and aluminum strip; nickel strip and copper foil; nickel strip and copper foil multi-layer; aluminum strip and aluminum foil multi-layer; aluminum shell and aluminum-nickel composite strip welding; nickel strip and copper foil multi-layer; aluminum strip and aluminum foil multi-layer; copper Pipe sealing; automobile wiring harness; motor terminal welding, etc.

NBC-UWL11A(40K)

NBC-UWL11A(40K)