CHINA QXD-500 Zirconia Ceramic Fineness gauge double-channel Fineness gauge 0~500μm

HuiNuo QXD-500 Double-channel Fineness Meter of zirconia ceramicsSPEC

HuiNuo QXD-500 Double-channel Fineness Meter of zirconia ceramicsDetails

HuiNuo QXD-500 Double-channel Fineness Meter of zirconia ceramicsPacking list

- SKU

- NB045139

- scraper material

- zirconia ceramics

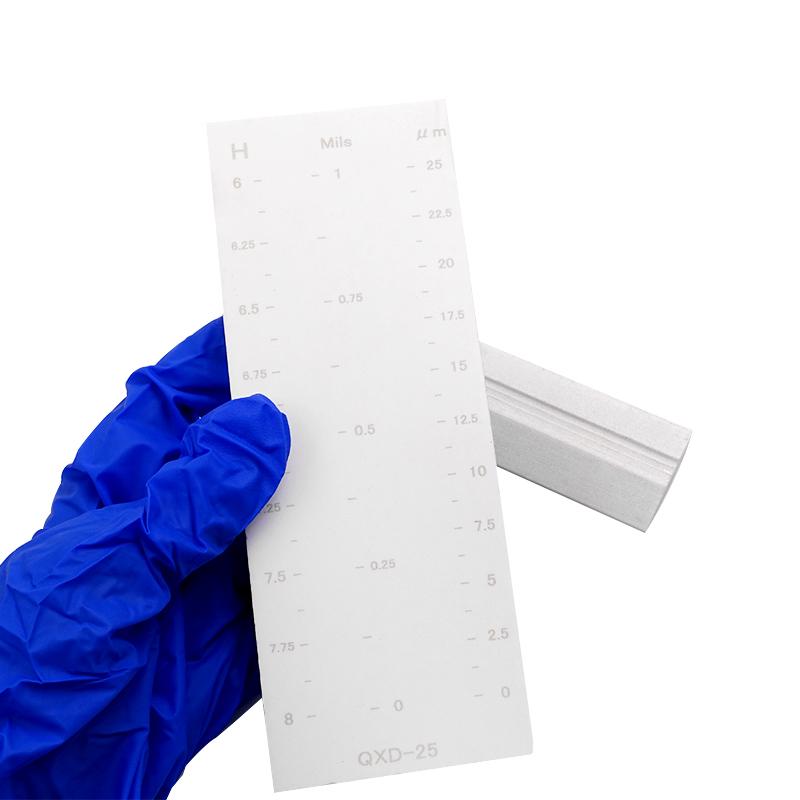

- range

- 0~500μm

- Graduation

- 25μm

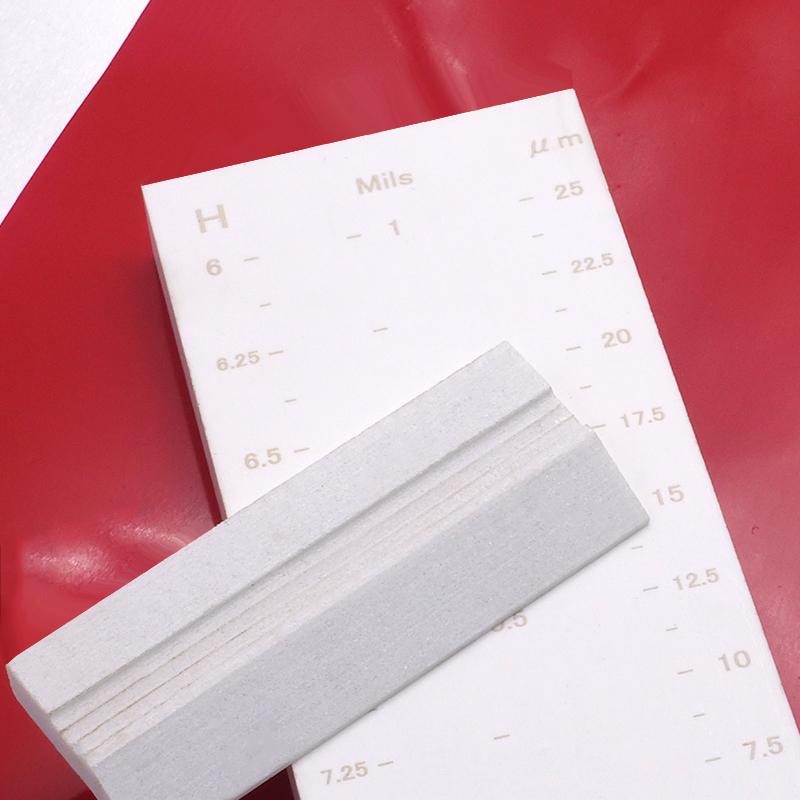

- Number of grooves

- Article 2

- Groove size

- 140*12.5mm

- Scraper type

- double-channel

- Dimensions

- 175 x65 x 13mm

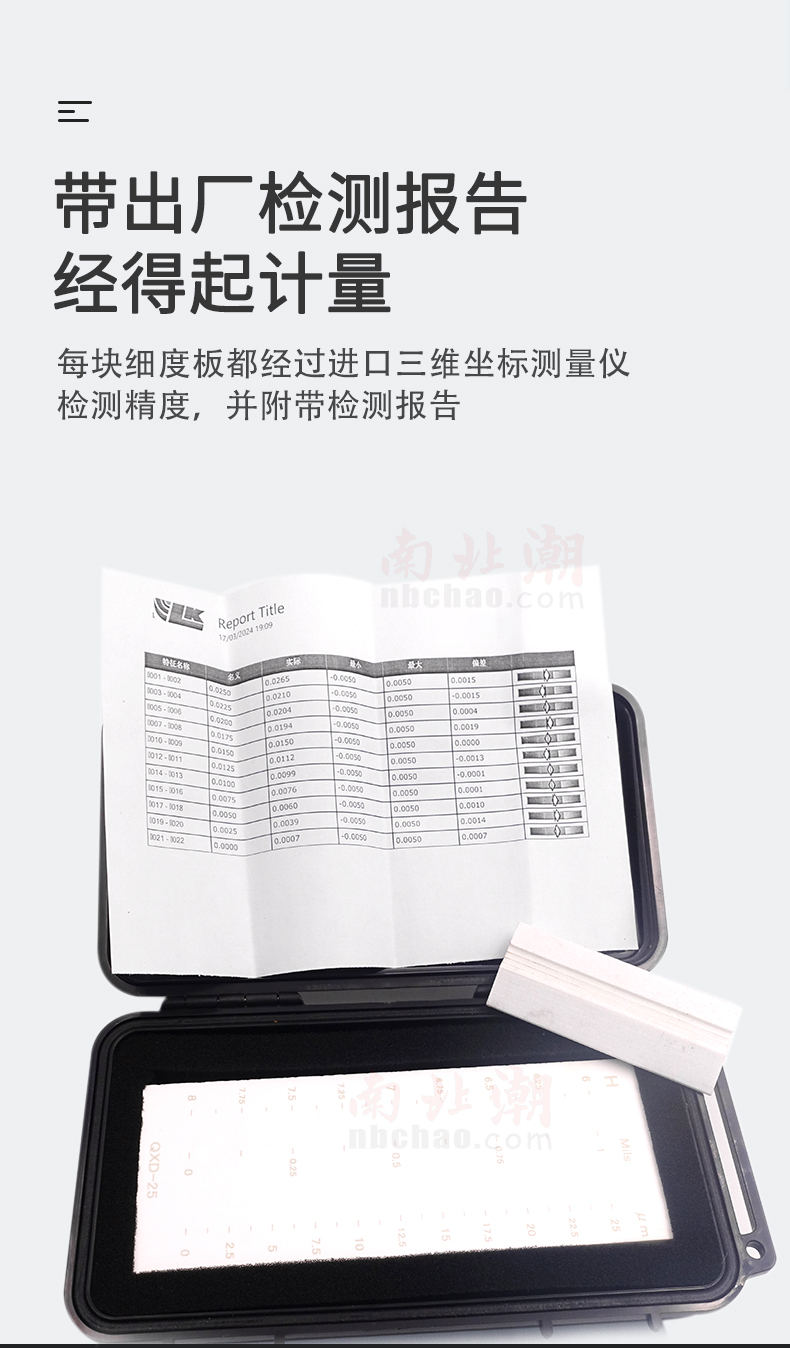

Introduction

A scraper Fineness Meter is an instrument used to measure the particle size distribution or particle size of substances such as paints, inks, pigments, cosmetics, etc. It is done by coating the sample on a flat substrate and then using a scraper to scrape the material flat, assessing the particle size and dispersibility of the sample based on the thickness of the remaining material on the scraper or the distribution of particles.

The domestic (CN) QXD-500 zirconia ceramic fineness plate is a double-groove Grindometer that meets the standard, with a range of 0~500μm and a groove size of 140×12.5mm.

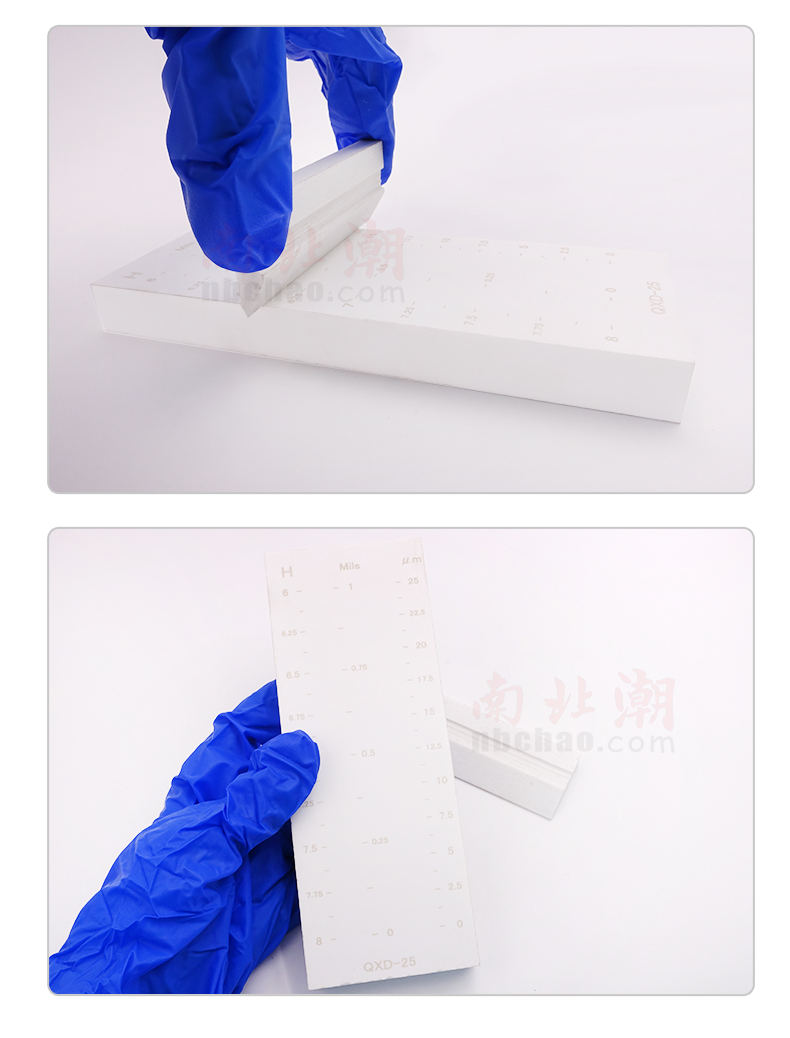

Advantages of zirconia ceramic

Hardness and wear resistance: Zirconia ceramics have high hardness and wear resistance, which allows them to keep the surface flat and stable during the measurement process, thereby improving the accuracy and repeatability of the measurement.

Chemical Stability: Zirconia ceramics have good stability to many chemicals and are not susceptible to corrosion or chemical reactions, which gives them an advantage in measurements involving chemical samples.

High temperature stability: Zirconia ceramics have good stability and resistance in high-temperature environments, making them suitable for applications that require measurements at high temperatures.

Insulation properties: Zirconia ceramics have good insulation properties and can be applied in the field of electrical and electronics.

Applications

It is used to determine the corrosive material test in the fields of coatings, paint pastes, plastics, inks, paper, etc.

QXD-500

QXD-500