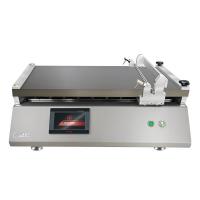

China NBC-A3-DJ6 Automatic Film Applicator with automatic feeding system

SEBar + Vacuum chuck + automatic feeding system, using pneumatic feeding system, effective coating area 850mm * 1000mm, standard 3L volume barrel.

$15734.00/set

PromotionLoading...

Coupon

Model:

zy

Manufacturer authorization

Similar products

zy NBC-A3-DJ6 Automatic Film ApplicatorSPEC

zy NBC-A3-DJ6 Automatic Film ApplicatorDetails

zy NBC-A3-DJ6 Automatic Film ApplicatorPacking list

- SKU

- NB045238

- Spreader Accuracy

- ±0.003mm

- Spreader thickness range

- 0~10mm

- Coating speed

- 5~ 180Mm/s (< 5mm/s can be customized)

- Coating size

- 850mm*1000mm

- Spreader speed

- Digital display, different speeds

- Coating rod specification

- Accuracy 0.001mm (Spreader thickness is determined according to the rod model)

- Host Power

- 220V 50Hz

- Dimensions

- Non-standard customization, subject to the actual order.

- speed control

- Infinitely variable speed

- Bottom plate material

- aluminum alloy

- Spreader Accuracy

- 0.001mm

- Customizable function

- Automatic inking system

- Customizable function

- Jet system device, UV solid inclusion device

- Feeding principle

- Air source pressure flows out

- Feed Sport Mode

- Reciprocating linear motion

- Feeding back and forth traverse speed

- 2-150mm/s

- spit Volume

- Adjustable (by adjusting the air pressure and the operating speed of the discharge port)

- Shaft drive mode

- Timer belt

- Feeding system air source

- 0.6Mpa, can be connected to the trachea of φ 8 (self-matching)

- Power Voltage of feeding system

- 220V,50Hz

- Tank pressure

- Maximum withstand 8Mpa

- Material of feeding barrel

- 304 stainless steel with a wall thickness of 4mm

- Feeding drum configuration

- Safety valve, pressure regulating valve, pressure gauge, relief valve

- Optional

- Leakage tank, substrate fixing fixture, trimming horizontal height support foot device, Glass plate, Silicone pad and Weight (for applications with uneven thickness of Spreader substrate), application width control baffle

- Speed regulation Accuracy

- 1mm/s

- Heating temperature range

- RT+~180℃

- Temperature Accuracy

- ±3℃

- Feeding drum Volume

- 3L

NBC-A3-DJ6

Automatic Film Applicator

Bar + Vacuum chuck + automatic feeding system, using pneumatic feeding system, effective coating area 850mm * 1000mm, standard 3L volume barrel.

NBC-A3-DJ6 floor-standing automatic coating machine with automatic feeding system is a wire rod scraper heating coating machine with an effective coating area of ââ850mm*1000mm. It comes standard with a 3L volume material barrel and a heating temperature of 180℃. It is often used in laboratories to make films, and is suitable for film making in coatings, inks, polymer materials, films, glues, pressure-sensitive adhesives and other industries.

Optional

FAQ

QIs the price listed on the website the final cost for overseas purchases?

ANo, it isn't. This is the ex-factory price of the product in the Chinese Mainland. In addition to this price, buyers from different countries need to account for additional costs such as shipping fees, tariffs, and others. For specific regional quotes, please consult our customer service or fill out a quotation form.

QWhat is the specific process for purchasing the product?

AFirst, please click on the quotation form on the website and fill in detailed information. Our customer service personnel will then send you a quotation based on your specific country and region, confirming payment and delivery methods. Following this, we proceed with contract signing, payment, and shipment. You can then await delivery.

QWhat should I do if the instrument I purchase needs repair?

AAfter-sales repair for overseas instruments is an unavoidable issue. Our repair terms stipulate that the sender is responsible for the shipping and insurance costs incurred for the repair. Repairs within the warranty period are free, while repair costs beyond the warranty period are determined based on the actual situation.

Knowledge

- 1Scraping machine selection case: film substrate large size high accuracy scraping solution

- 2How to install the wire rod applicator in the laboratory automatic coating machine?

- 3Automatic coating machine _ vacuum adsorption small coating machine how to install Vacuum Pump?

- 4Hot melt adhesive is applied on the film, how to choose the film coating machine?

- 5Selection skills of laboratory small automatic coating machine

- 6Laboratory automatic coating machine selection considerations

- 7Application of Film Applicator in electrode prepative

- 8Laboratory Film Applicator Drive Selection: Servo Motor and Stepper Motor

- 9Automatic Film Applicator Technology Introduction and Application

- 10Review of laboratory film coater technology and selection method

Standard

NBC-A3-DJ6

NBC-A3-DJ6