UK RK KHC.01.S short coating rod Drawdown Plate set, choose 8 models from 0 to 9 wire rods

SERK KHC.01.S Applicator rod Drawdown Plate SetSPEC

RK KHC.01.S Applicator rod Drawdown Plate SetDetails

RK KHC.01.S Applicator rod Drawdown Plate SetPacking list

- SKU

- NB000453

- Wire rod type

- RK short rod

- Number of bars

- 8 sticks

- Application width

- 140mm

- Drawdown Plate Model

- S.KHC.01(11*18cm)

- Number of Drawdown Plates

- 1

- Number of proofing paper

- 500 sheets (white)

- bracket

- KHC.30 (for cleaning and storing wire rods)

- Number of brackets

- 1

- Remarks

- The wire rod is from No. 0 to No. 9 wire rod, choose 8 models.

RK short wire rod set contains the following products

| product | quantity | Model specifications | Remark |

| RK short rod | 8 roots | Coating width 14cm | Choose from 8 models from wire rod sizes 0 to 9 |

| Imprinting bed | 1 | S.KHC.01 (11*18cm) | |

| Proofing paper | 500 sheets | ** | White |

| Bracket | one | KHC.30 | For cleaning and storing wire rods |

RK short wire rod set short wire rod model selection refer to the table below

Please select any 8 wire rod numbers from the following

| Product number | Product Description |

| KHC.10.0 | No. 0 short squeegee, with a white rubber tip at one end of the handshake, and the wet film thickness applied is 4 microns. |

| KHC.10.1 | No. 1 short scraper stick, with a yellow rubber tip at the handshake end, and the wet film thickness applied is 6 microns. |

| KHC.10.2 | No. 2 short squeegee, with a red rubber tip on one end of the handshake, and the wet film thickness applied is 12 microns. |

| KHC.10.3 | No. 3 short scraper stick, with a green rubber tip at the handshake end, and the wet film thickness applied is 24 microns. |

| KHC.10.4 | No. 4 short squeegee, with a black rubber tip at the handshake end, and the wet film thickness applied is 40 microns. |

| KHC.10.5 | No. 5 short squeegee, with a golden brown rubber tip at the handshake end, and the wet film thickness of the coating is 50 microns. |

| KHC.10.6 | No. 6 short squeegee, with an orange rubber tip on one end of the handshake, and the wet film thickness applied is 60 microns. |

| KHC.10.7 | No. 7 short scraper stick, with a brown rubber tip at the handshake end, and the wet film thickness of the coating is 80 microns. |

| KHC.10.8 | No. 8 short squeegee, with a blue rubber tip on one end of the handshake, and the wet film thickness of the coating is 100 microns. |

| KHC.10.9 | No. 9 short squeegee, with a brown rubber tip at one end of the handshake, and the wet film thickness applied is 125 microns. |

| The Total length of the short squeegee rod is 24.50cm, and the coating width is 14cm; the diameter of the short squeegee rods No. 0~4 is 0.3cm, and the diameter of the short squeegee rods No. 5~9 is 0.9cm. | |

How to use RK short wire rod set

1. First prepare a substrate of appropriate size for proofing.

RK company can provide two types of proofing paper for proofing (500 sheets per package, half of the proofing paper is coated with varnish, and the other half is without varnish) RK model list

â For small imprinting beds, the specification is 12Ã21cm

â For large imprinting beds, the specification is 18Ã31cm

2. Place the substrate on the imprinting bed and clamp it with clamps.

3. Select a suitable type of short squeegee rod (please refer to relevant information) and place it on the imprinting bed, close to the clamp.

4. Place the paint or varnish used for proofing near the clamp, about 1cm below the ink filament stick. (Please control the dosage yourself)

5. Hold both ends of the short squeegee rod with both hands, and pull the ink wire rod toward the operator at a constant speed and pressure. Please be careful not to rotate the wire rod during the operation.

6. After proofing, clean the short wire rods in a suitable solvent and wipe them dry with a cloth. Please note that the wire rod should always be kept dry

Application fields of RK short wire rod set

Short wire rods are used in research, testing and quality control in the testing of inks, coatings, adhesives and various emulsions. Applicable substrates for RK wire rods include paper, cardboard, plastic film, metal foil, etc.

The functions of each product in RK short wire rod set

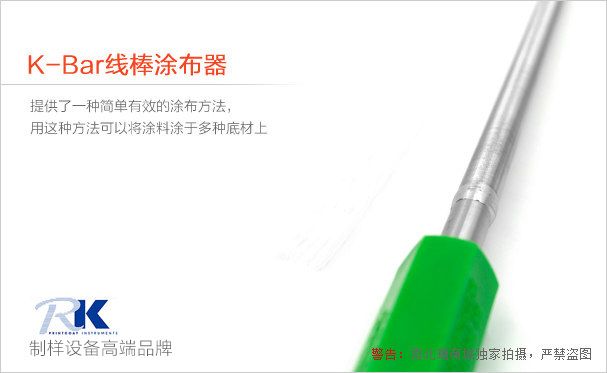

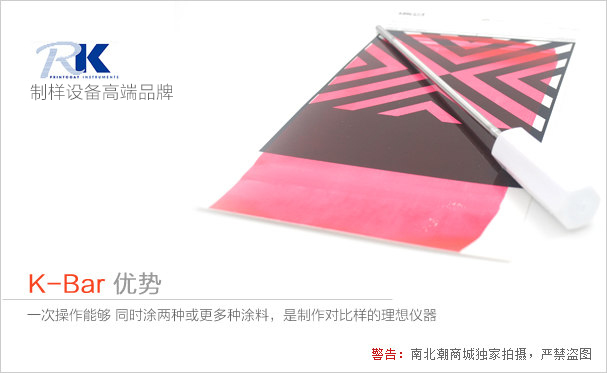

| K Hand Coater short line rod: Provides a simple and effective coating method that can be used to apply coatings to a variety of substrates, including paper, cardboard, plastic film, foil, metal plates, glass plates, wooden boards, etc. Two or more coatings can be applied simultaneously in one operation, making it an ideal instrument for making comparison samples. |

| RK imprinting bed: Used with the RK imprinting bed, compared to proofing directly on hard substrates, proofing on the RK imprinting bed has better repeatability and proofing effects. This is because the soft imprinting bed can absorb the pressure exerted by the operator on proofing to a certain extent, thus making the proofing effect better. |

| RK imprinting bed: Used with the RK imprinting bed, compared to proofing directly on hard substrates, proofing on the RK imprinting bed has better repeatability and proofing effects. This is because the soft imprinting bed can absorb the pressure exerted by the operator on proofing to a certain extent, thus making the proofing effect better. |

- 1Bar Spreader Technology: Principles, Applications and Advantages over Miscellaneous coating methods

- 2Application of Mayer Rods in 2D Single Crystal Copper Nanosheet Films

- 1YS/T 680-2016《Powder for coating aluminium alloy extruded profiles for architecture》

- 2HG/T 2006-2006《Thermosetting powder coatings》

- 3GB/T 22374-2018《Floor coating》

- 4GB/T 1727-2021《General methods for preparation of coating films》

- 5GB/T 23997-2009《Solvent-thinned polyurethane wood coatings for indoor decorating and refurbishing》

- 6HG/T 20720-2020《Construction and acceptance specification of waterborne anti-corrosion coatings for steel structures in industrial buildings》

- 7HG/T 5370-2018《Waterborne coatings for bicycles》

- 8HG/T 3951-2007《Water based colorants for architectural coatings》

- 9GB/T 13217.1-2020《Test method for colour and tinctorial strength of ink》

- 10HG/T 3948-2007《Hot Melt Adhesives for Sanitary napkin & Panty liner》

KHC.01.S

KHC.01.S