TQC VF2175 4-sided Coating Applicator 50/100/150/200µm

SE-

JINGKELIAN SZQ 50/100/150/200 Film Applicator film thickness 50/100/150/200μm$ 142.00SE

JINGKELIAN SZQ 50/100/150/200 Film Applicator film thickness 50/100/150/200μm$ 142.00SE -

MODERNER Frame 50/100/150/200 Large Frame Applicator Stainless Steel Wet Film Applicator 90mm

MODERNER Frame 50/100/150/200 Large Frame Applicator Stainless Steel Wet Film Applicator 90mm -

MODERNER Frame type 50/100/150/200 Large frame type 4-sided Applicator film width 80mm

MODERNER Frame type 50/100/150/200 Large frame type 4-sided Applicator film width 80mm -

MODERNER Frame 50/100/150/200 Large Frame Applicator Groove Width 60mm

MODERNER Frame 50/100/150/200 Large Frame Applicator Groove Width 60mm -

MODERNER Combo - 50/100/150/200 Quadrilateral Preparation 78x100

MODERNER Combo - 50/100/150/200 Quadrilateral Preparation 78x100

TQC sheen VF2175 4-Sided Coating ApplicatorSPEC

TQC sheen VF2175 4-Sided Coating ApplicatorDetails

TQC sheen VF2175 4-Sided Coating ApplicatorPacking list

- SKU

- NB004557

- type

- Frame 4-sided

- WFT

- 50/100/150/200µm

- Application width

- 80mm

- Accuracy

- ±3μm

- material

- High grade stainless steel

- standard

- ASTM D823

- size

- 75*20*25mm/1115*20*20mm

Introduction

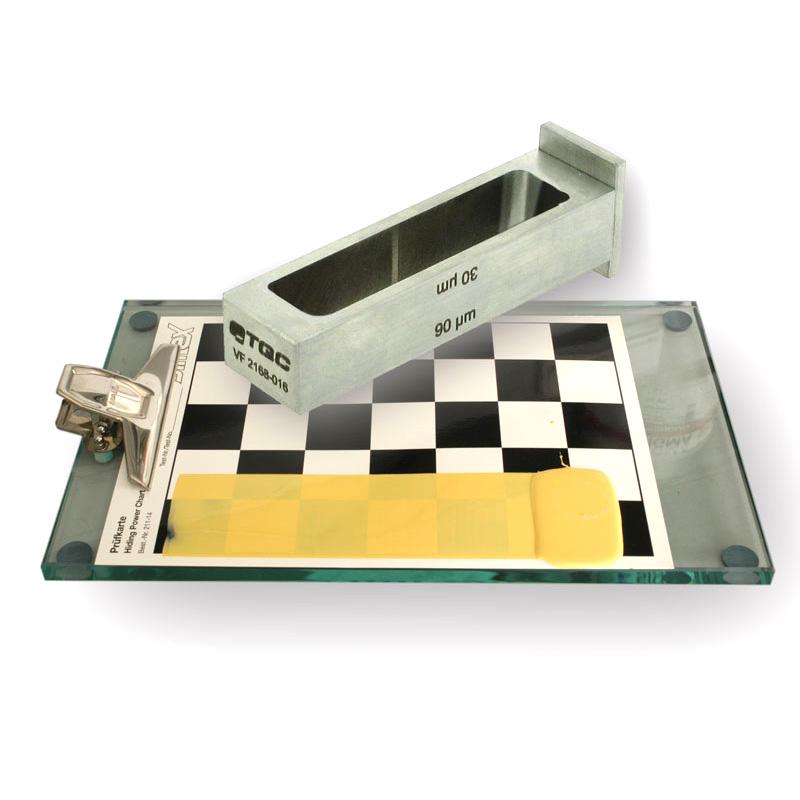

The TQC brand four-sided Film Applicator is made of stainless steel, produced in accordance with international standards, with a strictly controlled production process and engraved with a unique serial number.

●The multi-functional four-sided Film Applicator can prepare 4 kinds of wet film with different thicknesses

●A guide smear is attached to one side of the lacquer applicator, and the guide smear can also be removed.

●The material is stainless steel to ensure that the applicator is not eroded by acidic or alkaline substances in the paint or cleaning agent.

By simply changing the angle, 4 different film thicknesses can be obtained, which is easy to operate.

Parameters

| Model | Coating film thickness | Coating width | precision | size | Material | Meets standards |

| VF2168 | 15/30/60/90 µm | 60mm | ±3μm | 75x20x25mm/1115x20x20mm | stainless steel | ASTM D823 |

| VF2169 | 30/60/90/120 µm | 60mm | ||||

| VF2170 | 50/100/150/200 µm | 60mm | ||||

| VF2173 | 15/30/60/90 µm | 80mm | ||||

| VF2174 | 30/60/90/120 µm | 80mm | ||||

| VF2175 | 50/100/150/200 µm | 80mm |

Product detail drawing

Introduction to paint leveling

Usually the method of direct observation with the naked eye is to compare the sample with the standard sample in parallel to judge the quality of the leveling of the coating film, which varies from person to person and is highly subjective. The essence of leveling refers to the smooth state of the coating film after the construction of the coating, and the surface with good leveling should not have irregular forms such as orange peel, brush marks, corrugations, and shrinkage holes.

Take you to the Dutch TQC

- 1GB/T 17001.3-2025《Anti-counterfeiting printing ink—Part 3:Thermochromic anti-counterfeiting printing ink》

- 2GB/T 1727-2021《General methods for preparation of coating films》

- 3HG/T 20720-2020《Construction and acceptance specification of waterborne anti-corrosion coatings for steel structures in industrial buildings》

- 4HG/T 5065-2016《Finishing varnishes for architectural coatings》

- 5HG/T 3951-2007《Water based colorants for architectural coatings》

- 6GB/T 13217.1-2020《Test method for colour and tinctorial strength of ink》

- 7GB/T 9755-2014《Synthetic resin emulsion coatings for exterior wall》

- 8ASTM D823-2018《Paints, varnishes and related products of uniform thickness on the test board》

- 9GB 1727-1992《Paint film general preparatory method》

VF2175

VF2175