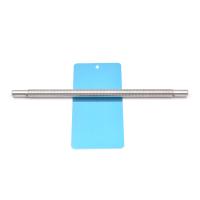

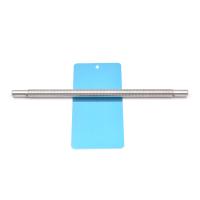

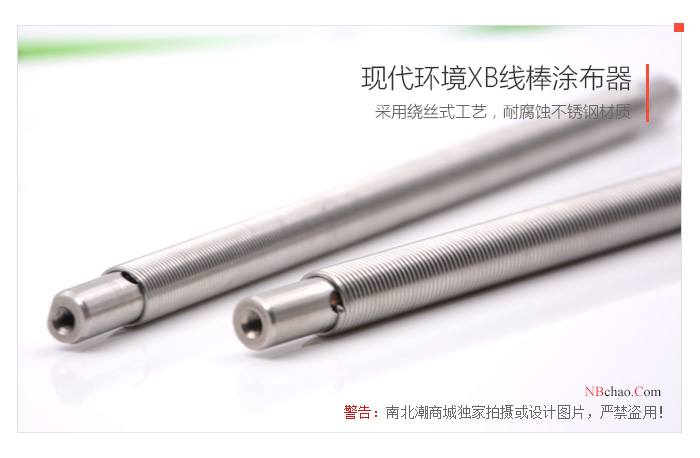

MODERNER XB-25 Wire bar WFT 25μm

-

Japan OSP-25/400 Paint Film Applicator WFT 25μm length 400mm$ 173.00SE

Japan OSP-25/400 Paint Film Applicator WFT 25μm length 400mm$ 173.00SE -

Japan OSP-25/250 Wet Film Applicator WFT 25μm Length 250mm$ 153.00SE

Japan OSP-25/250 Wet Film Applicator WFT 25μm Length 250mm$ 153.00SE -

Japan OSP-25/60 formed Applicator rod WFT 25μm length 60mm$ 116.00SE

Japan OSP-25/60 formed Applicator rod WFT 25μm length 60mm$ 116.00SE -

Japan OSP-22/60 Applicator rod WFT 22μm length 60mm$ 116.00SE

Japan OSP-22/60 Applicator rod WFT 22μm length 60mm$ 116.00SE -

Pushen XB-I 25μm XB rod, length 240mm$ 98.00SE

Pushen XB-I 25μm XB rod, length 240mm$ 98.00SE

Moderner XB-25 Mayer RodSPEC

Moderner XB-25 Mayer RodDetails

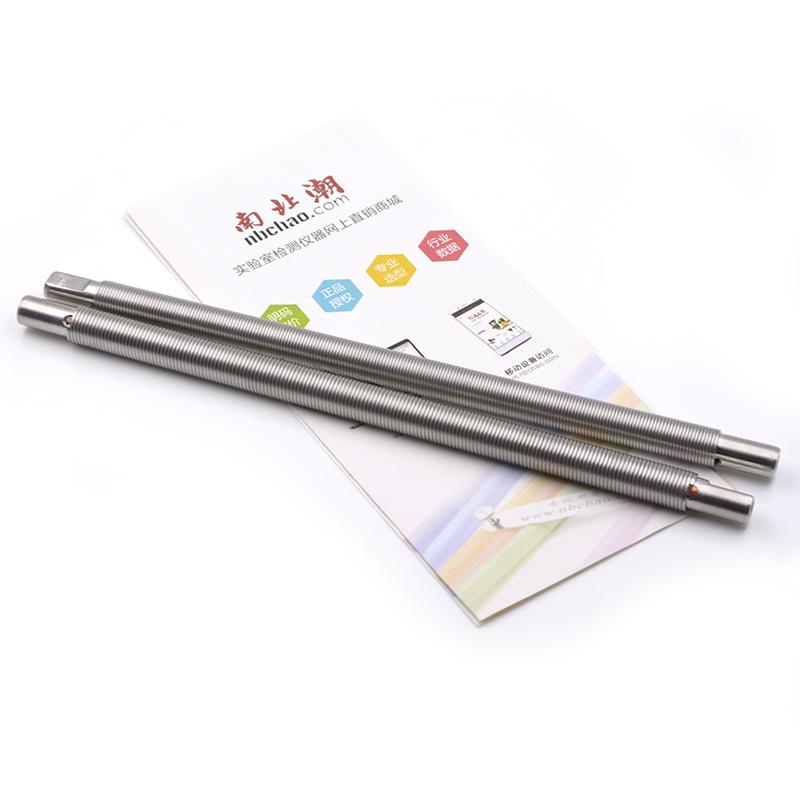

Moderner XB-25 Mayer RodPacking list

- SKU

- NB004558

- Production process

- Wire-wound

- WFT

- 25μm

- Total length

- 240mm

- Application width

- 200mm

- grip width

- 20+20mm

- material

- stainless steel

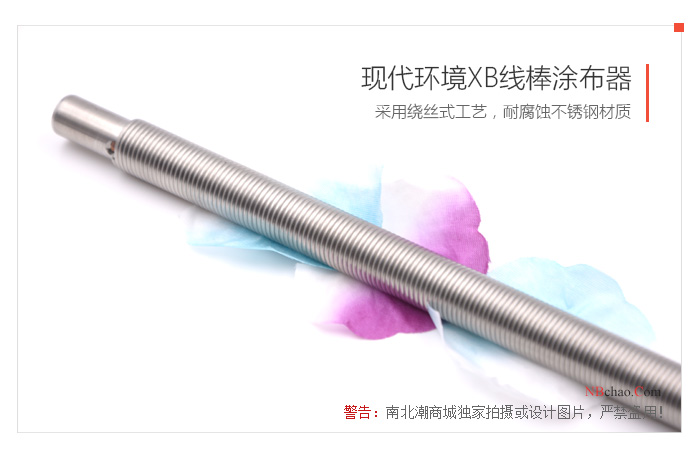

Introduction to XB-25 wire rod

MODERNER XB-25 wire bar is a wire-wound wire bar applicator used in laboratories to prepare coating films of specific thickness. The XB-25 wire bar coating film thickness is 25 microns and the coating width is 200mm. XB-25 wire rod is made of stainless steel and has good corrosion resistance. It can be used with a handle (sold separately) to make coating easier and more effective.

Specifications

| model | XB-7 | XB-10 | XB-12 | XB-15 | XB-20 | XB-25 | XB-30 | XB-40 | XB-50 | XB-60 | XB-80 | XB-100 | XB-120 | XB-150 | XB-200 | XB-250 | XB-300 |

| Wet film thickness (μm) | 7 | 10 | 12 | 15 | 20 | 25 | 30 | 40 | 50 | 60 | 80 | 100 | 120 | 150 | 200 | 250 | 300 |

| Total length (mm) | 240 | 240 | 240 | 240 | 240 | 240 | 240 | 240 | 240 | 240 | 240 | 240 | 240 | 240 | 240 | 240 | 240 |

| Coating width (mm) | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 |

Note: XB wire rod applicator needs to purchase an additional handle

Instructions

First, place the sample on the platform and fix it to ensure that the sample cannot move when the XB coating scraper passes over it.

Second, select the appropriate XB coating scraper according to the required wet film thickness and place it at the position specified on the sample.

Third, pour an appropriate sample in front of the xb coating scraper, hold the handle (need to be purchased separately) with your hand, and slide it at a constant speed of 150 mm/second, that is, apply a wet film with the required thickness.

Note: The XB coating scraper must be washed and dried with an appropriate solvent immediately after use to prevent the paint from drying out after too long and making it difficult to clean, causing blockage and affecting subsequent experiments.

Product actual pictures

Optional

- 1ASTM D4147-2023《Standard Practice for Applying Coil Coatings Using Wire-Wound Drawdown Bars》

- 2GB/T 13217.1-2009《Test method for colour of liquid ink》

- 3GB/T 13217.7-2009《Test method for adhesion to substrate of liquid ink with tape》

- 4GB/T 13217.1-2009《Test method for colour of liquid ink》

- 5ASTM D4147-2023《Standard Practice for Applying Coil Coatings Using Wire-Wound Drawdown Bars》

- 6ASTM D823-2018《Paints, varnishes and related products of uniform thickness on the test board》

- 7GB/T 9270-1988《Paints - Determination of contrast ratio (polyester membrane method) (EQV ISO 3906; 1980)》

XB-25

XB-25