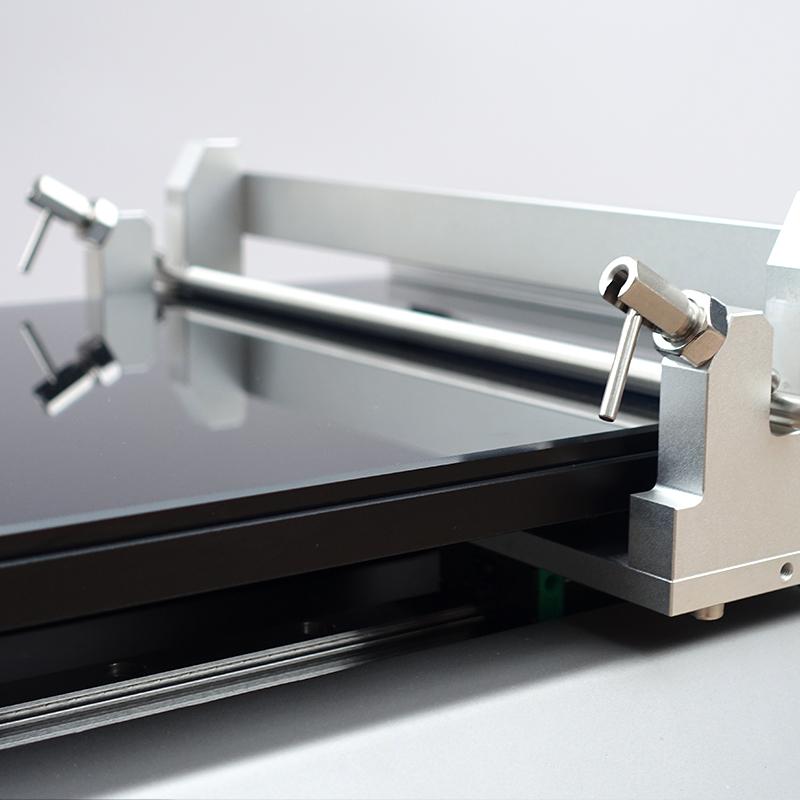

Bar coating, with heating function, simple bar groove design, bar installation is simple, Smoothness hardened aluminum alloy baseplate, wear resistance and scratch resistance.

$3830.00/set

PromotionLoading...

Coupon

Model:

Similar products

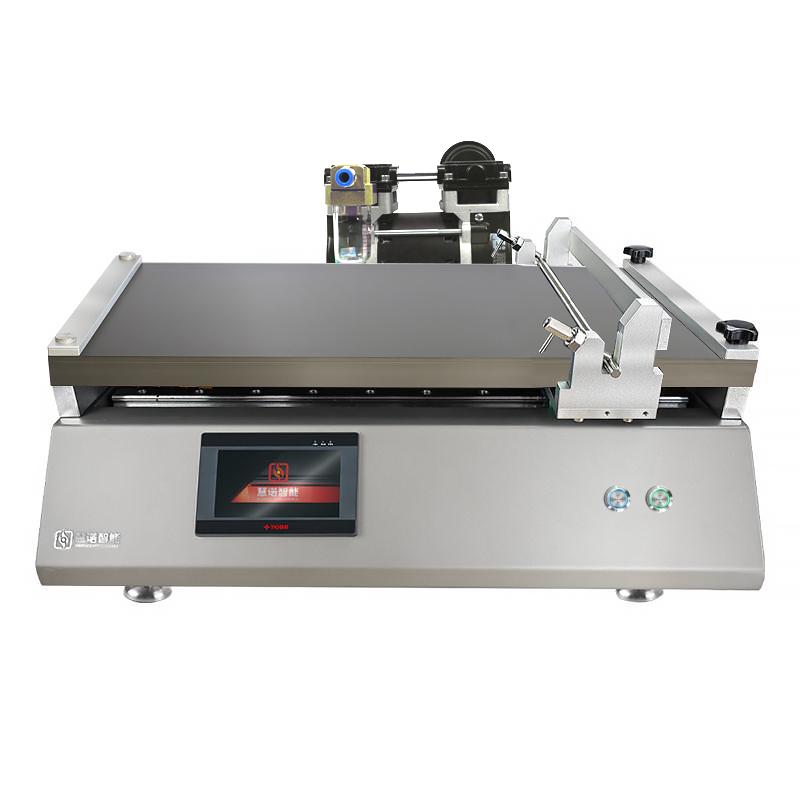

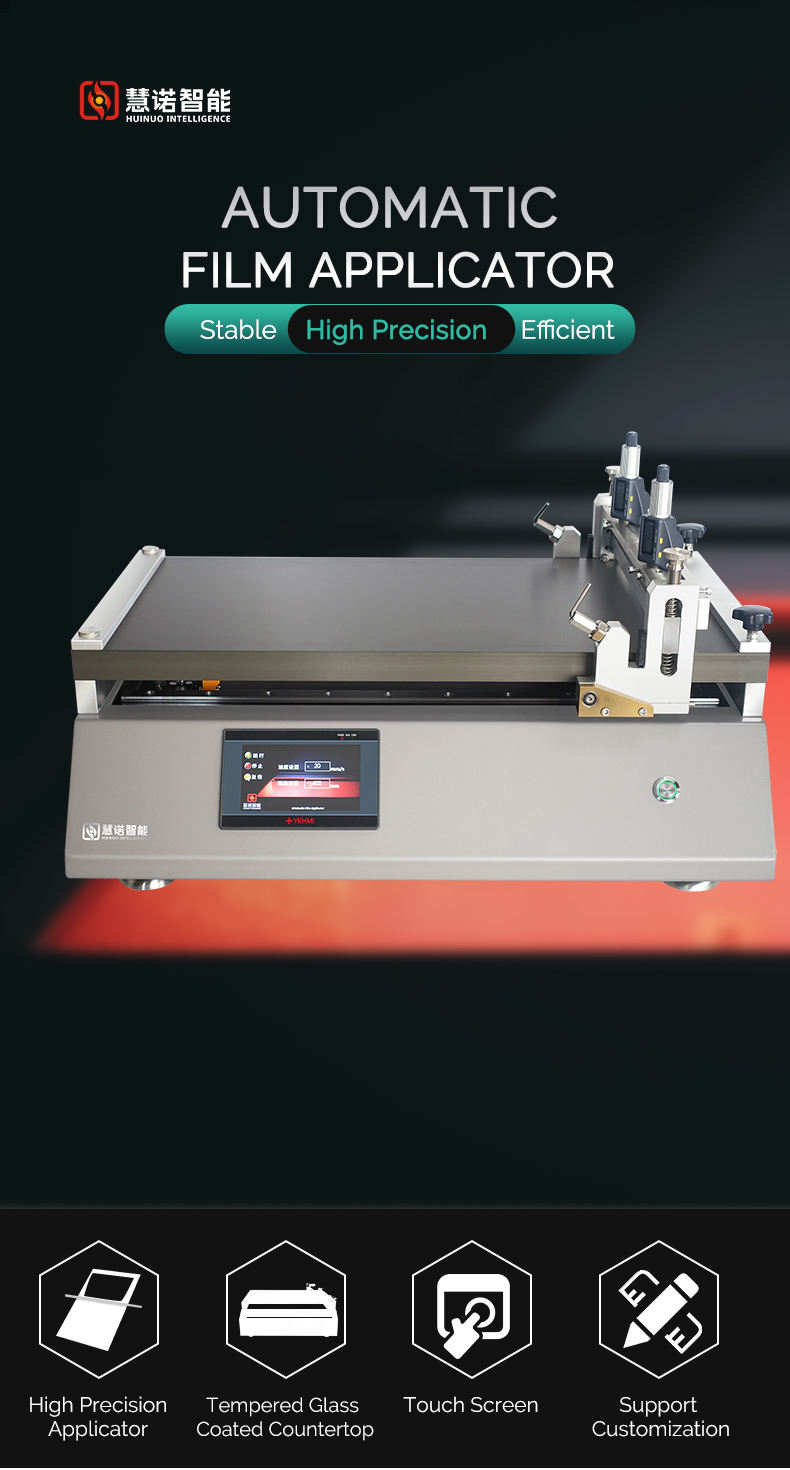

HuiNuo TM1300 Automatic Film ApplicatorSPEC

HuiNuo TM1300 Automatic Film ApplicatorDetails

HuiNuo TM1300 Automatic Film ApplicatorPacking list

- SKU

- NB045715

- coating method

- Bar Spreader

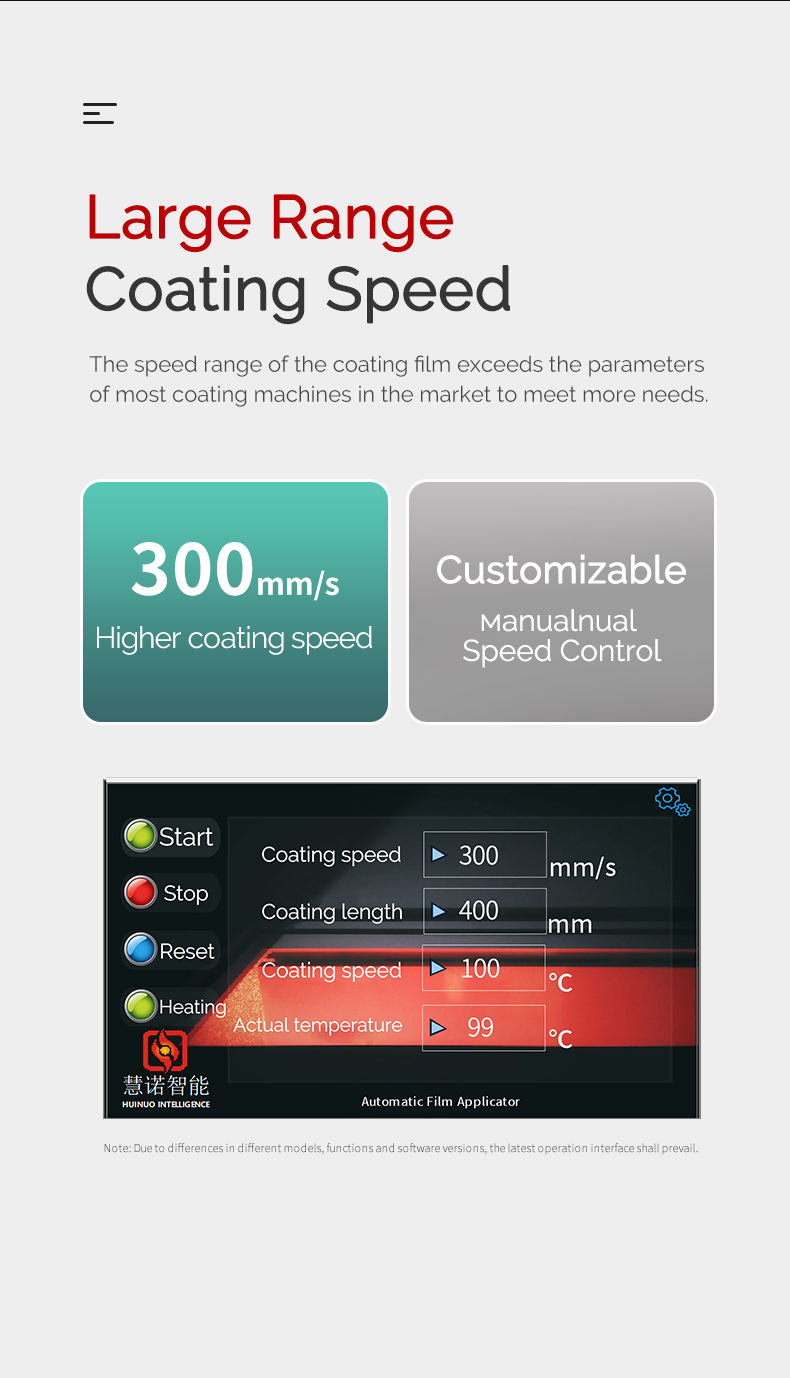

- coating speed

- 1~ 300Mm/s stepless speed regulation (can be customized)

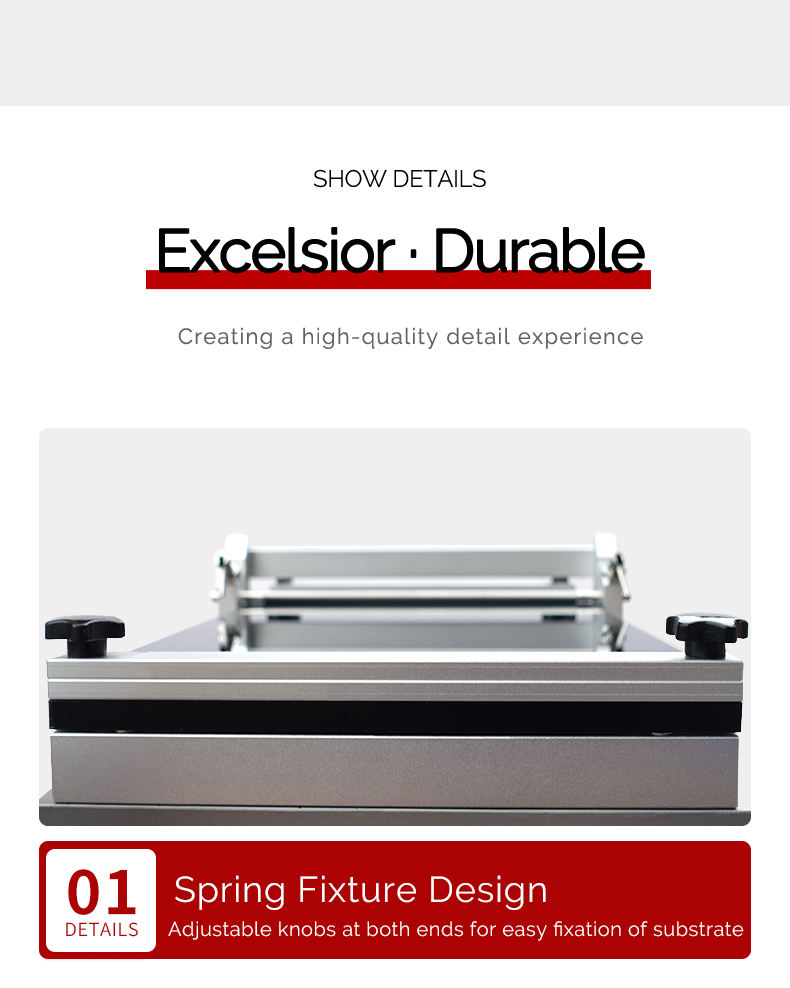

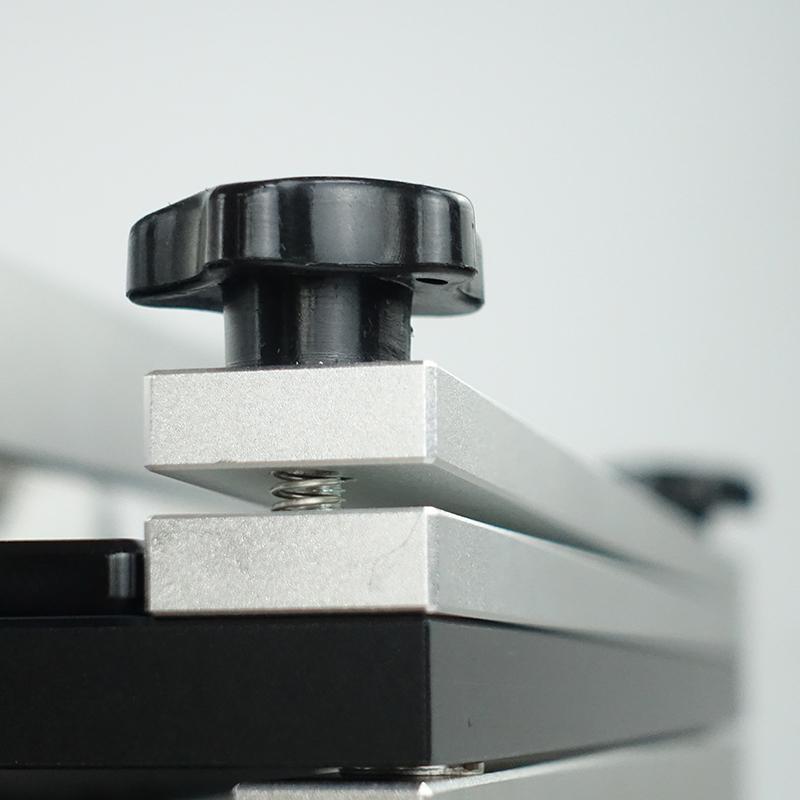

- Substrate clamping method

- Vacuum chuck + fixture

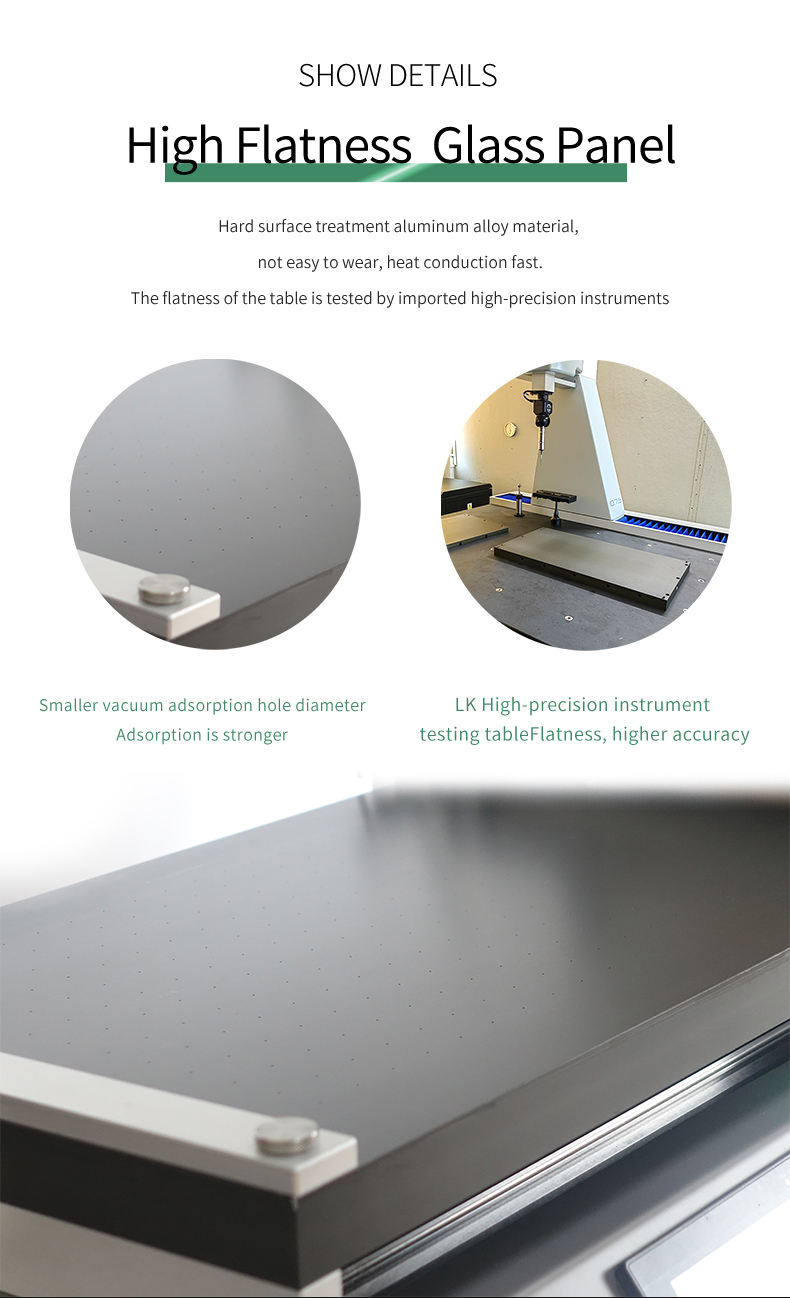

- Coating table material

- Surface hard treatment aluminum alloy

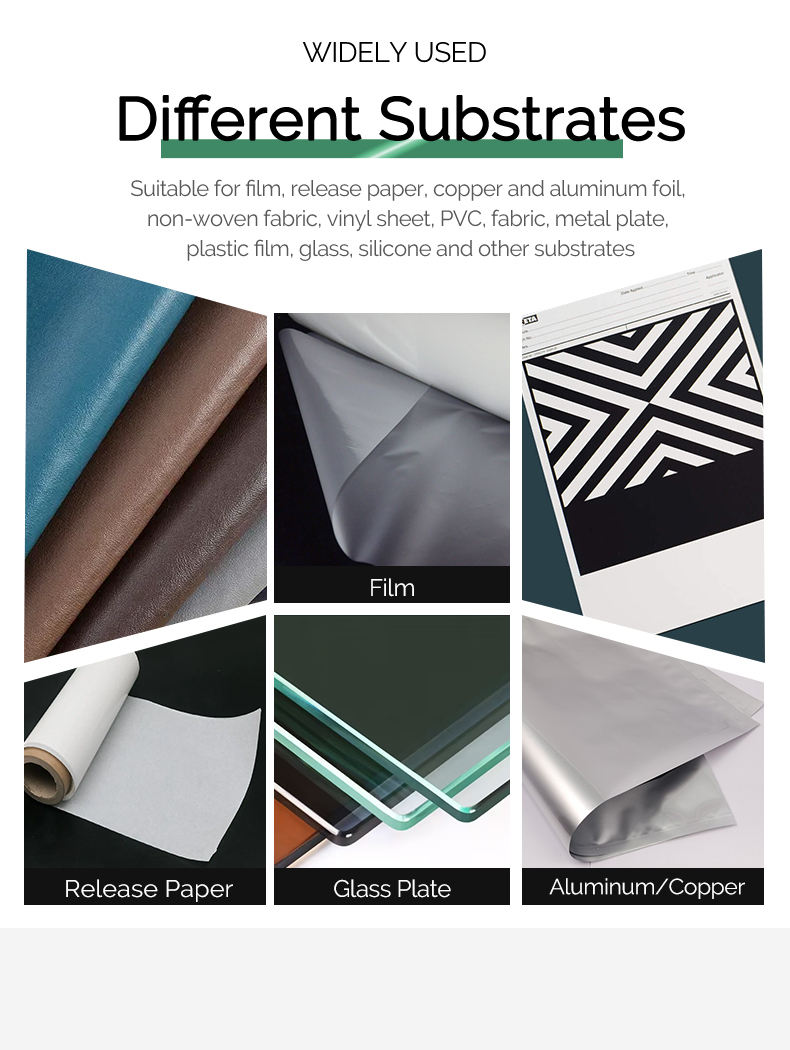

- Coating table size

- 600*300mm

- effective coating area

- 400 * 300Mm (can be customized)

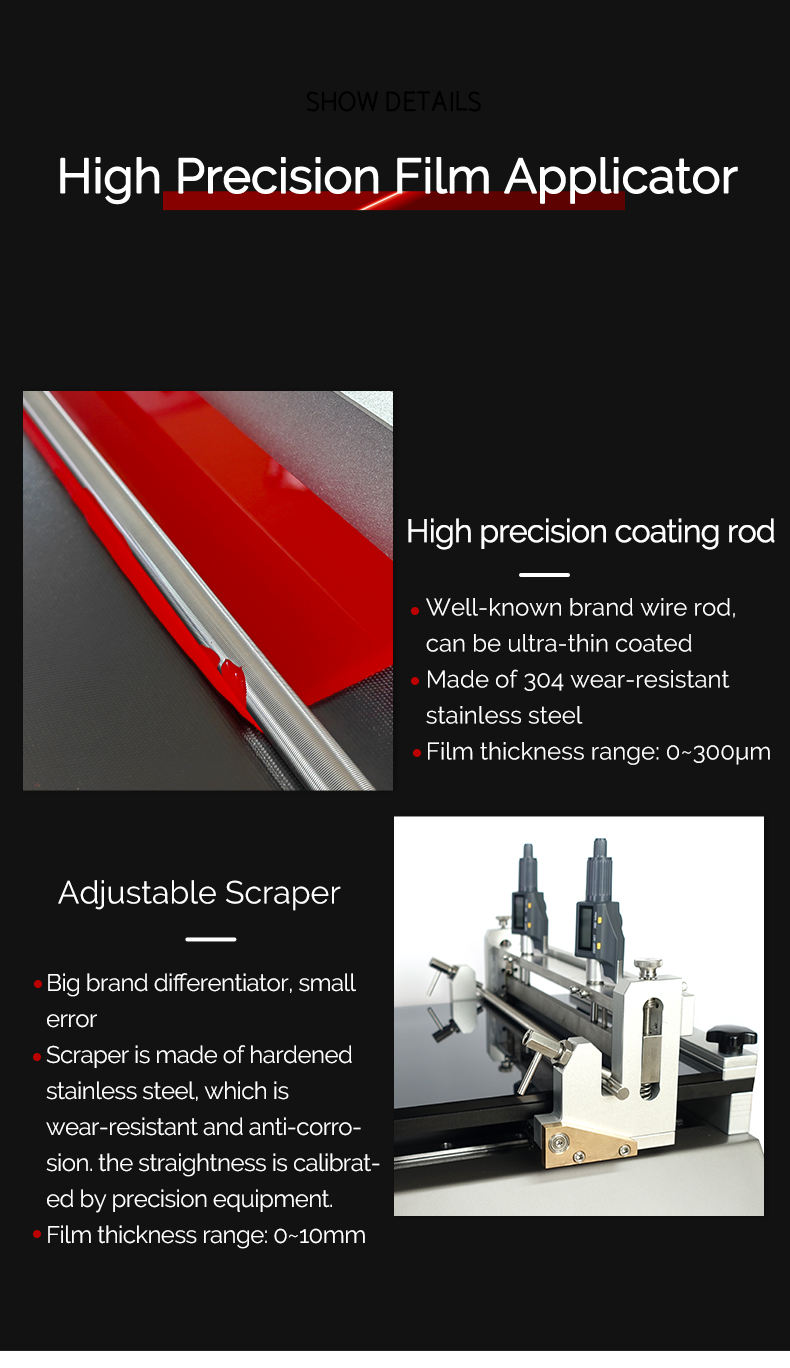

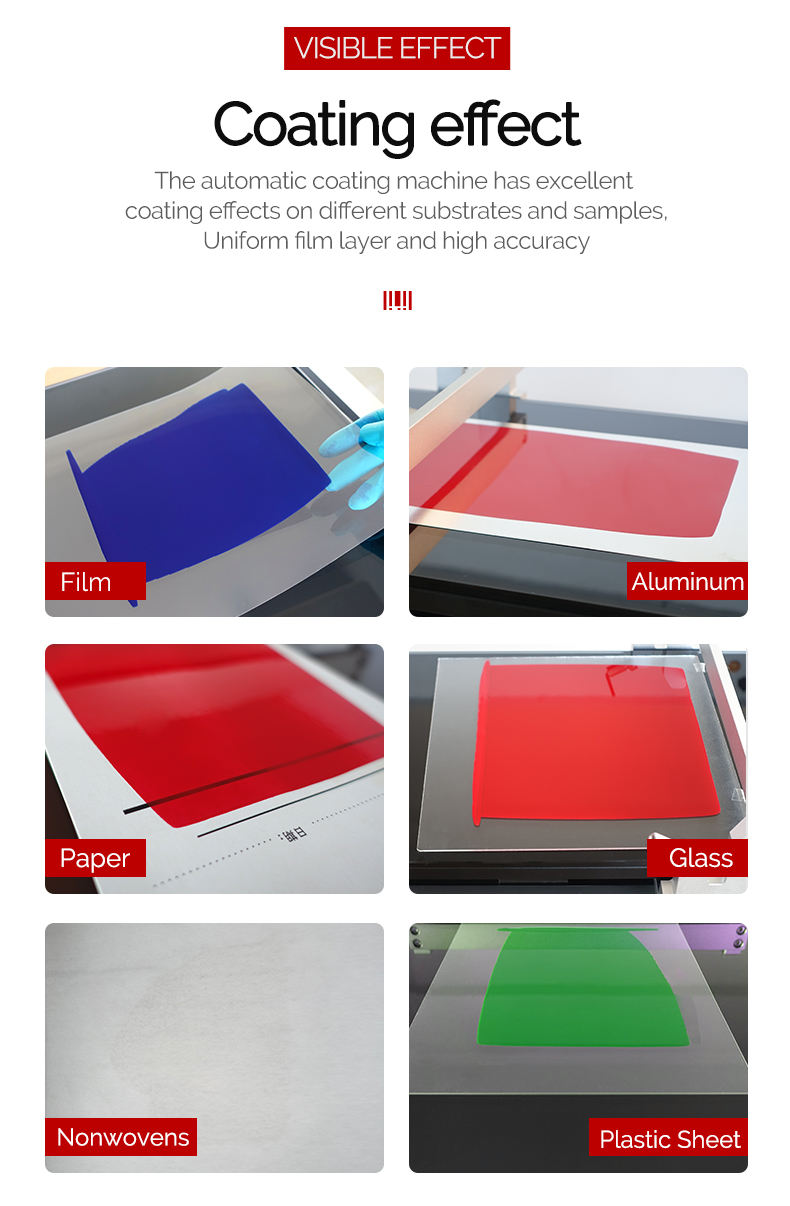

- meyer rod coating thickness range

- Different bar thickness, High Accuracy imported bar

- meyer rod coating accuracy

- ±0.001mm

- Vacuum Area

- 480 * 260Mm (can be customized)

- Vacuum aperture diameter

- Φ0.8mm

- Vacuum hole pitch

- 20*20mm

- Vacuum pump pumping rate

- 5.4m3/h

- Ultimate vacuum degree

- 50KPa

- Vacuum Pump Power

- 180W

- Vacuum pump weight

- 7.1kg

- Heating mode

- Mica sheet heating (optional graphene heating, faster thermal conductivity)

- Heating Temperature range

- RT +~ 180 ℃ (can be customized)

- Temperature Uniformity

- ±1℃

- Operating language

- Chinese (can be customized in English)

- display screen

- Color LCD Touchscreen

- Host power supply

- 100V~220V/50~60HZ

- Power

- 1800W

TM1300

Automatic Film Applicator

Bar coating, with heating function, simple bar groove design, bar installation is simple, Smoothness hardened aluminum alloy baseplate, wear resistance and scratch resistance.

FAQ

QDo proton exchange membrane, film Film thickness 8 microns, to drawdown blade heating Vacuum chuck bar, is this?

A

TM1300 is the bar heated Vacuum chuck model, and TM3300 is the drawdown Bar & Blade heated Vacuum chuck model.

QSilica gel, three layers thickness, 10~ 20μm, substrate release film, which Film Applicator is suitable?

A

Recommended wire rod heating vacuum adsorption, can meet the demand.

QDo your Film Applicators have any lame plating for steel bars? Steel bars are round.

A

The cylindrical one cannot be painted.

QOn the pi film substrate, a thickness of several microns, with heating function, which Film Applicator is suitable?

A

Vacuum adsorption Film Applicator can be heated with a wire rod, and the wire rod can be scraped thin to 1.5 microns.

QHow to Avoid Bubbles and Wrinkles in Film Applicator Spreader?

A

During the Spreader process, it is necessary to ensure that the Spreader area is clean and air is excluded in time to avoid bubbles and wrinkles.

QHow does the Spreader Stage Size of Film Applicators Affect the Spreader Material Selection?

A

The size of the Spreader stage of the Film Applicator will affect the coverage area of the Spreader material and the Spreader effect. A larger Spreader stage can Spreader a larger size substrate.

QWhat areas are Film Applicators particularly suitable for?

A

Film Applicators are particularly useful in laboratories in the fields of New Materials, Lithium Battery, Glue, Resin, etc. for preparing thin film samples and conducting experimental studies.

QWhat are the advantages of this Film Applicator's servo motor over traditional motors?

A

The advantage of using a servo motor is that it has higher running Stability, which can provide more accurate Spreader control and higher Spreader accuracy, and is suitable for laboratory applications that require high Spreader accuracy.

Standard

TM1300

TM1300