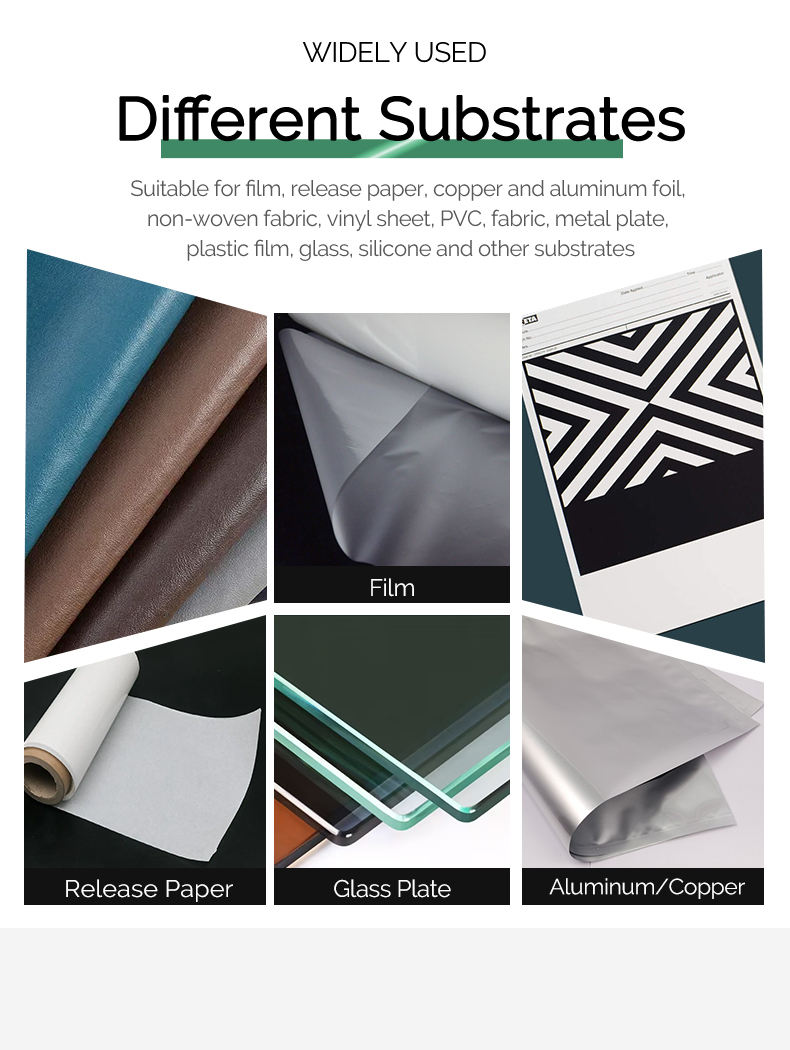

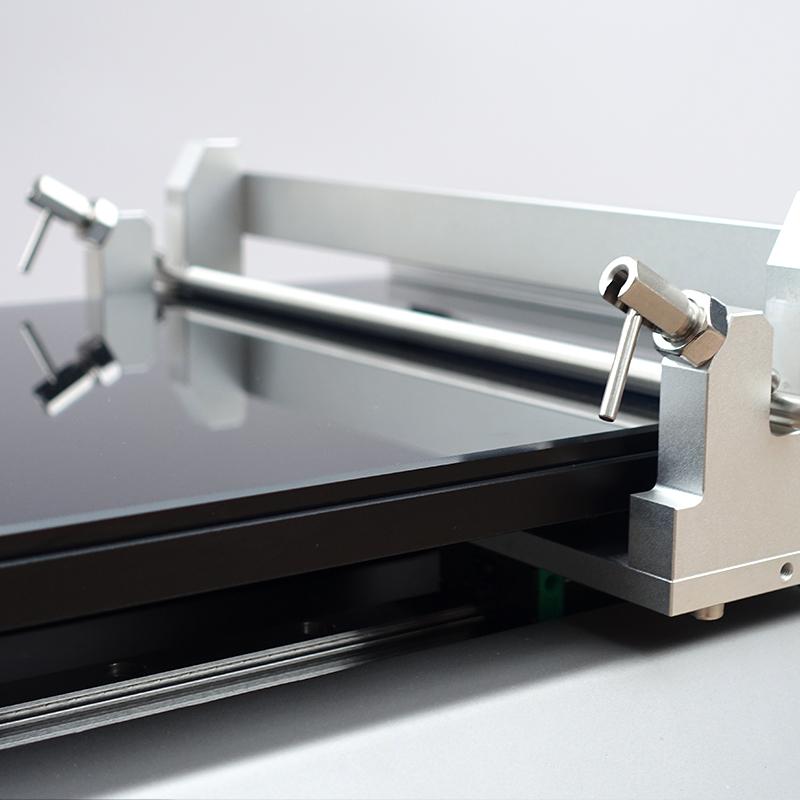

Wire rod Spreader, with heating function, servo motor, simple wire rod groove design, wire rod installation is simple, Smoothness hardening treatment aluminum alloy baseplate, wear resistance and scratch resistance.

$3987.00/set

PromotionLoading...

Coupon

Model:

Similar products

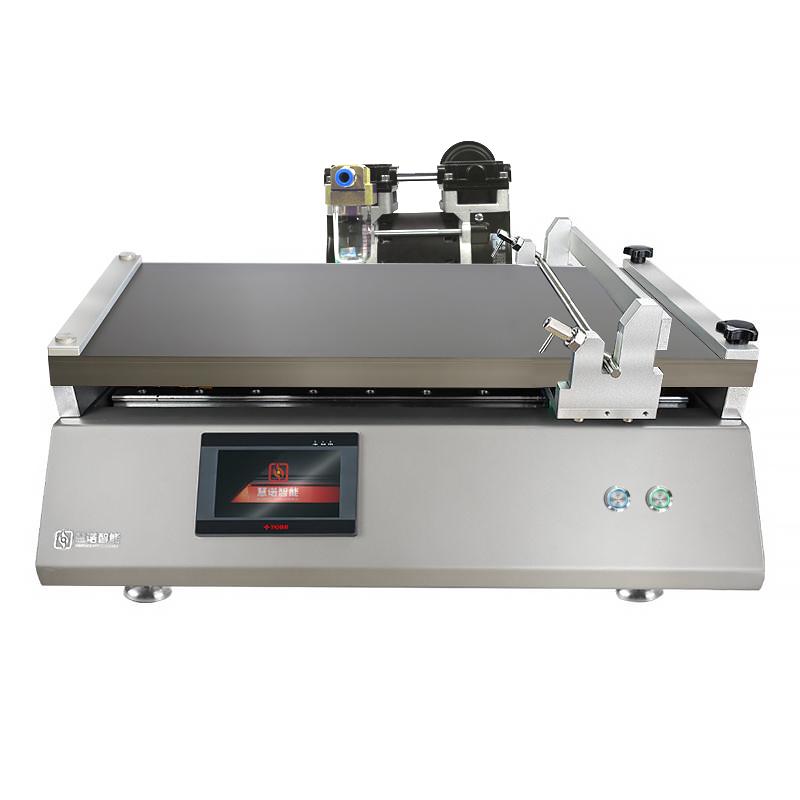

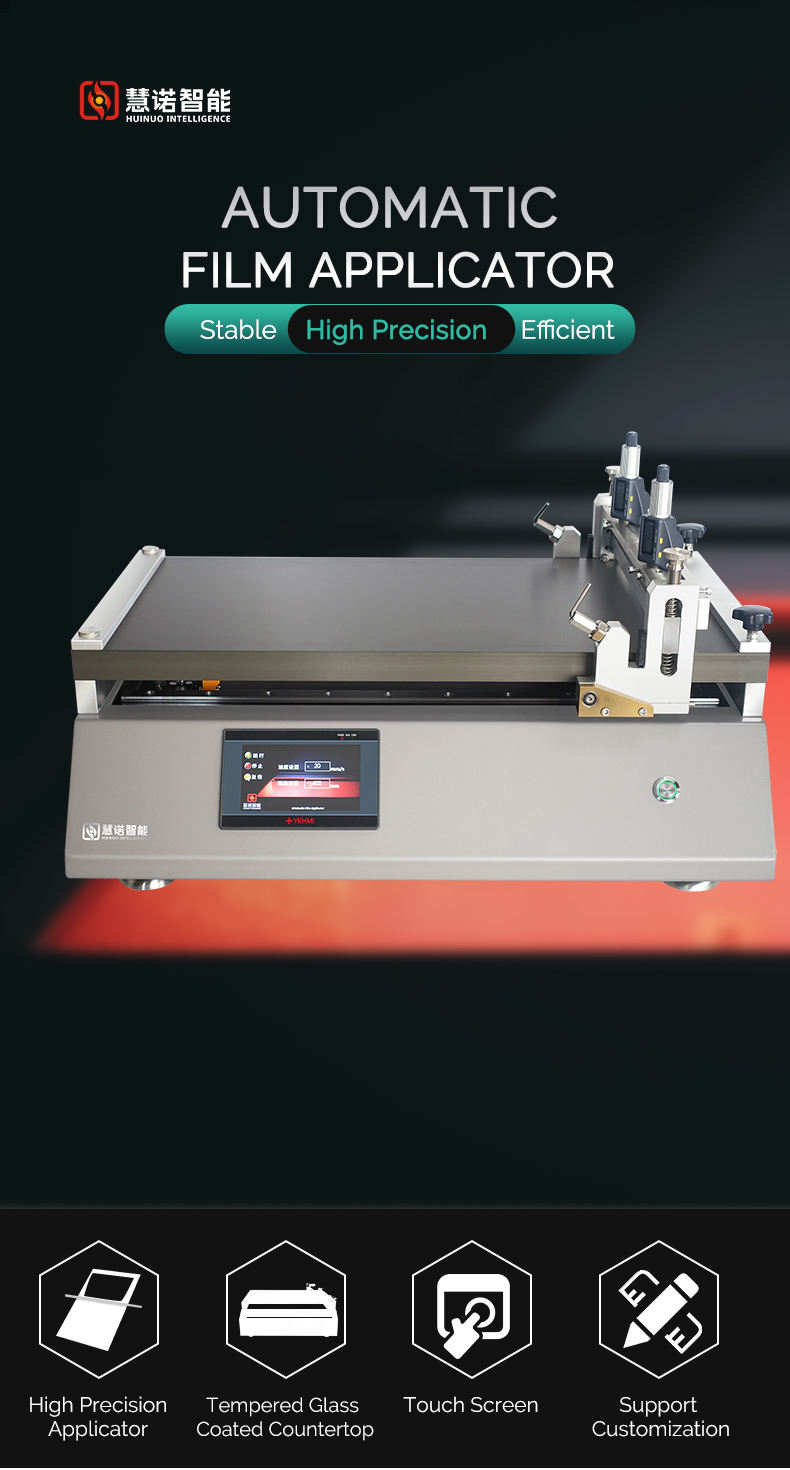

HuiNuo TM1300pro Automatic Film ApplicatorSPEC

HuiNuo TM1300pro Automatic Film ApplicatorDetails

HuiNuo TM1300pro Automatic Film ApplicatorPacking list

- SKU

- NB045716

- Coating method

- Rod

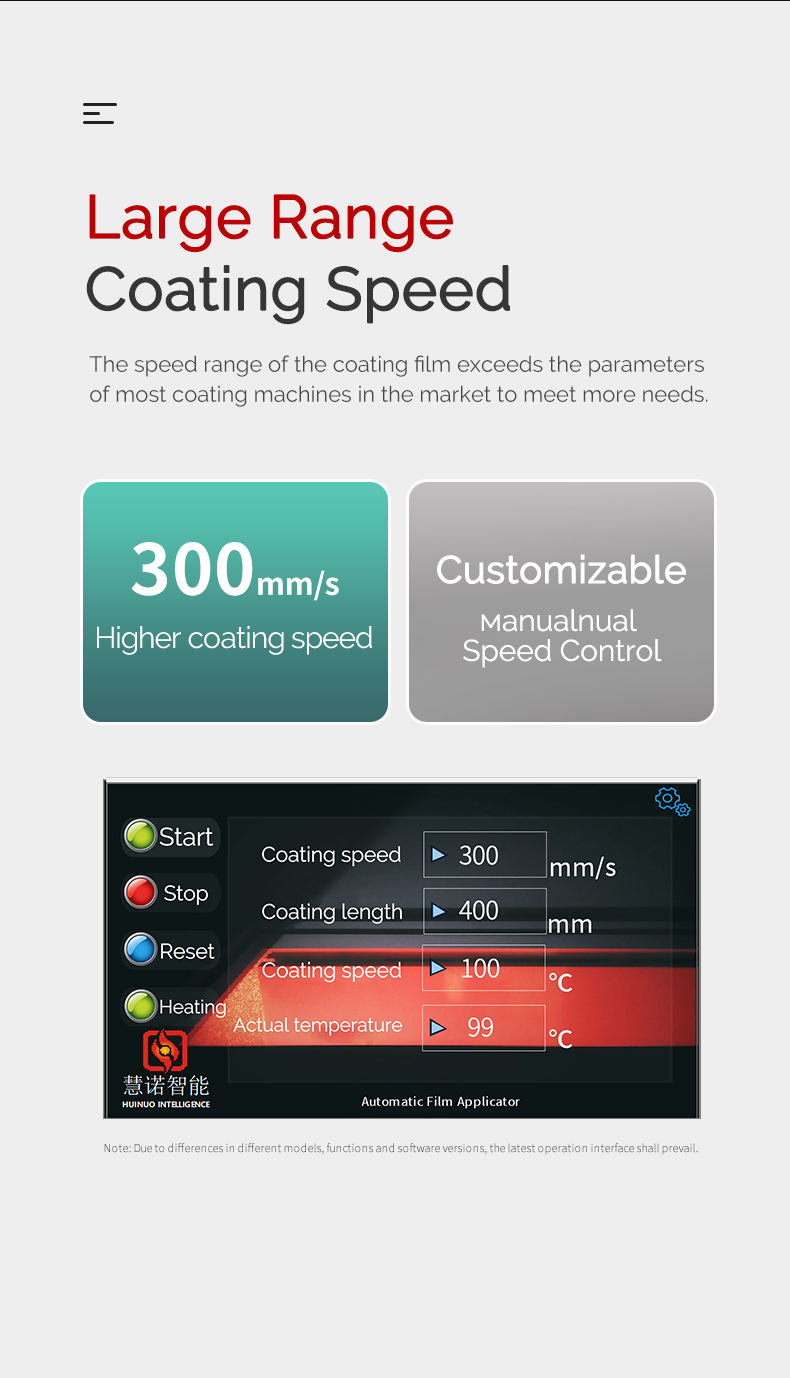

- Coating speed

- 1~ 300Mm/s stepless speed regulation (can be customized)

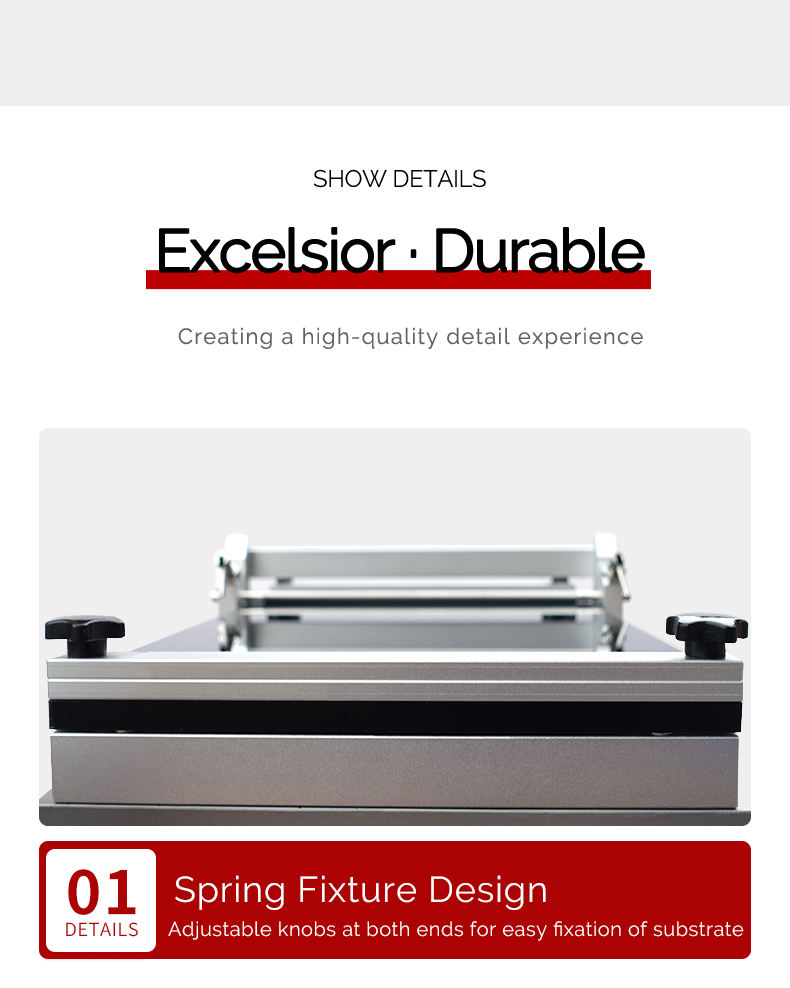

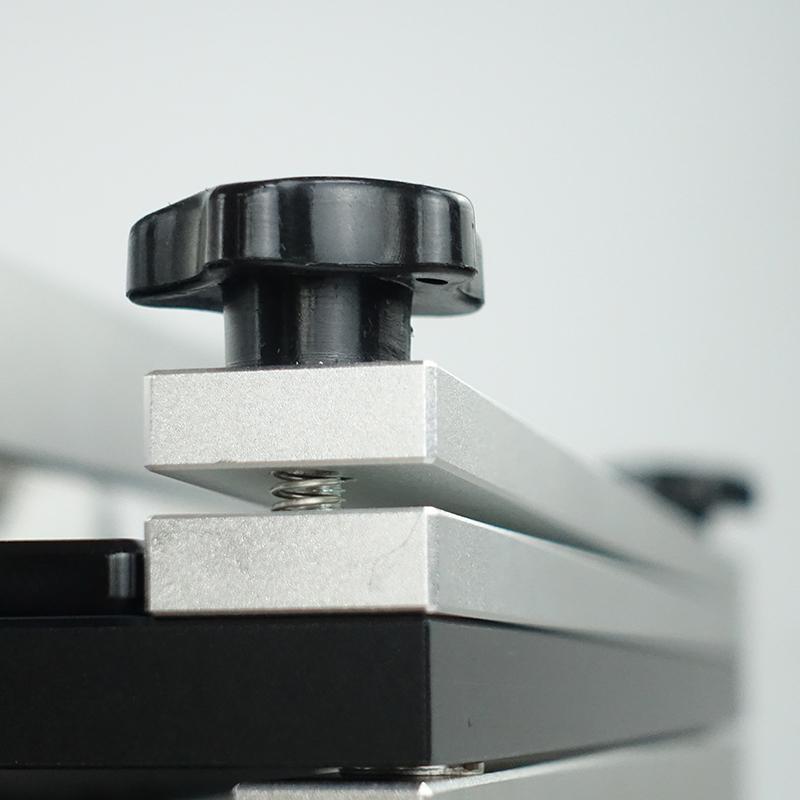

- Substrate clamping method

- Vacuum adsorption + fixture

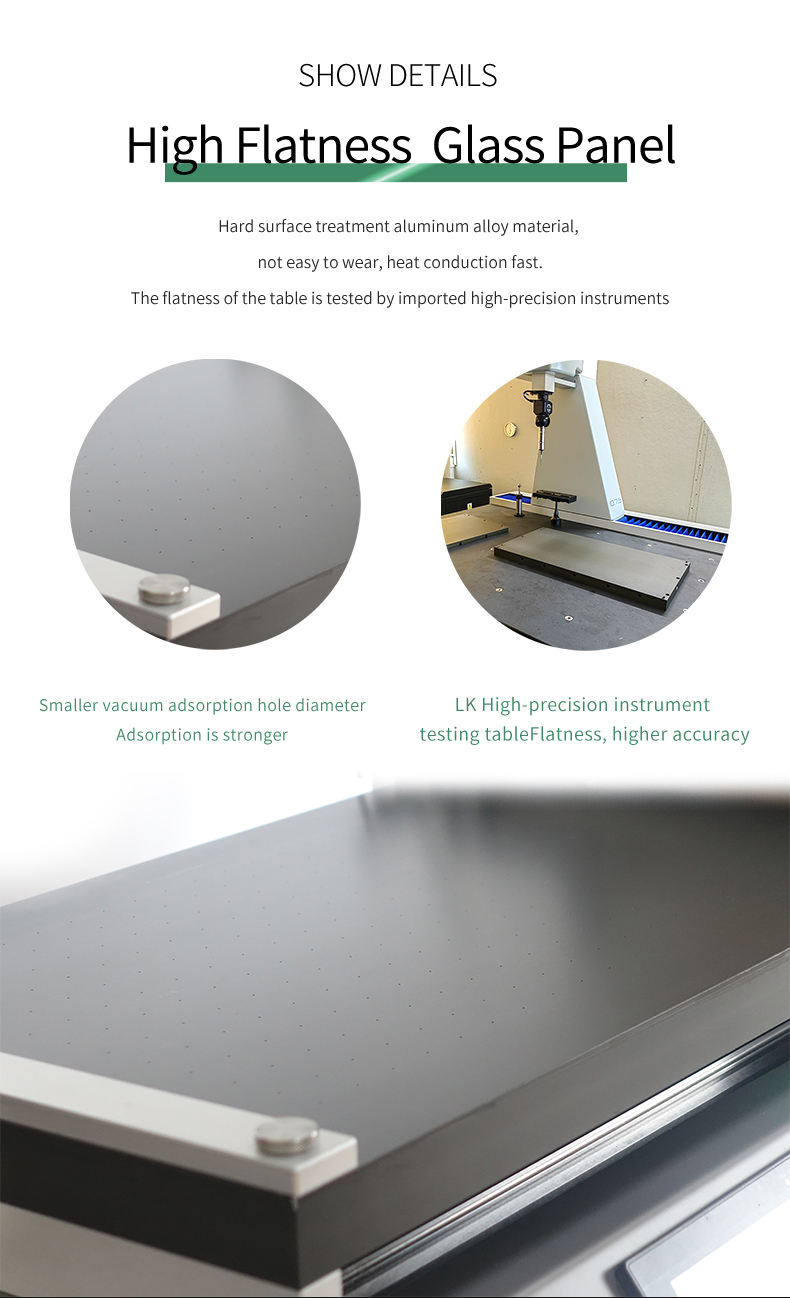

- Coating table material

- Surface hard treatment aluminum alloy

- Coating table size

- 600*300mm

- Effective coating Area

- 400 * 300Mm (can be customized)

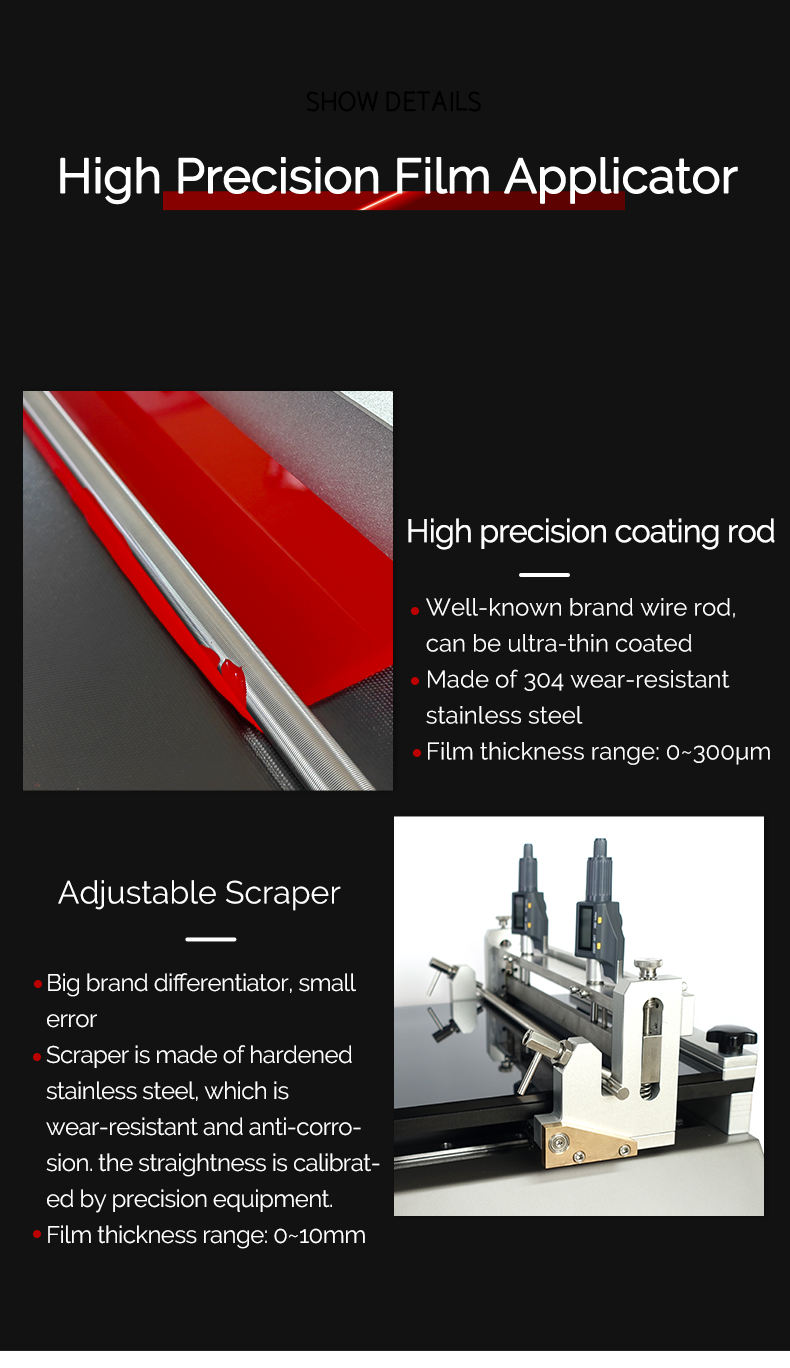

- Mayer Rod Thickness Range

- Different bar numbers have different thicknesses, with high-precision imported bars

- Mayer Rod Accuracy

- ±0.001mm

- Vacuum Area

- 400 * 300Mm (can be customized)

- vacuum aperture

- Φ0.8mm

- Vacuum hole spacing

- 20*20mm

- Pumping Speed

- 5.4m3/h

- Ultimate Vacuum

- 50KPa

- Vacuum Pump Power

- 180W

- Vacuum pump Weight

- 7.1kg

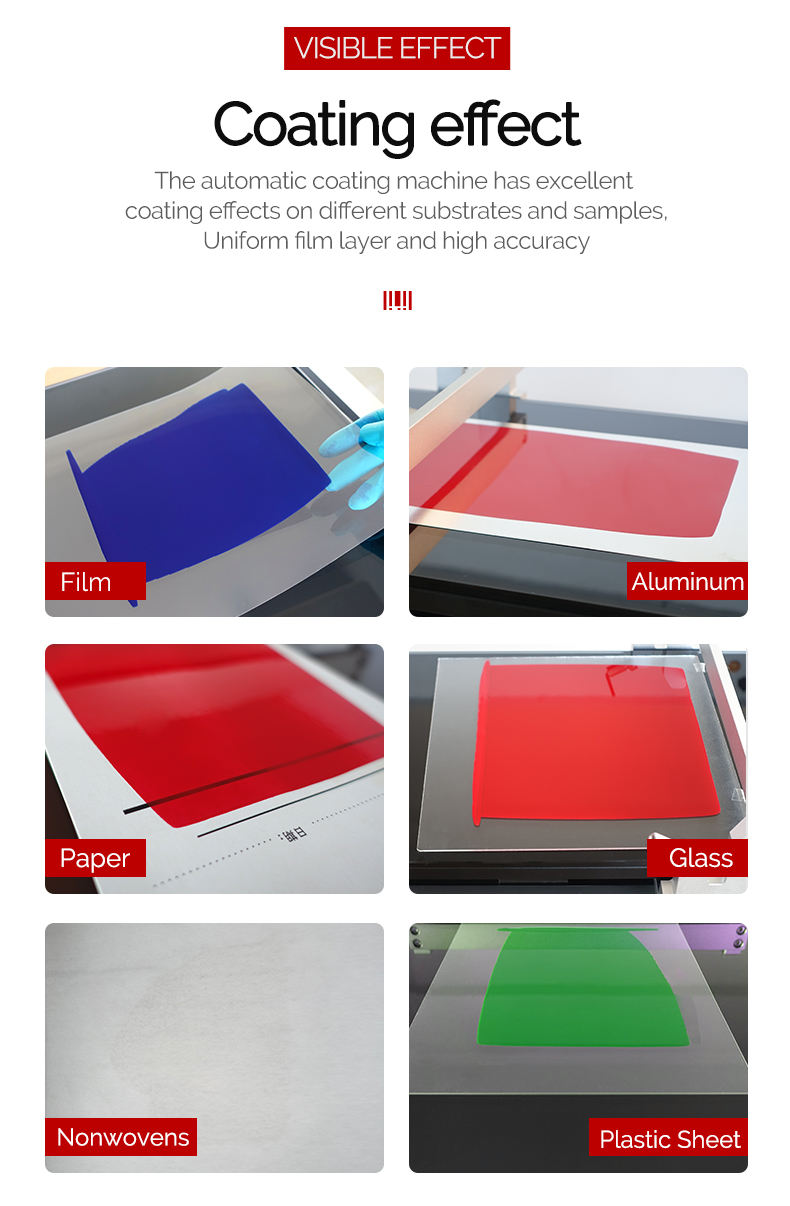

- Heating mode

- Mica sheet heating (optional graphene heating, faster thermal conductivity)

- Heating Temperature range

- RT +~ 180 ℃ (higher temperature can be customized)

- Temperature Uniformity

- ±1℃

- Drive motor

- Servo motor

- Operating language

- Chinese (can be customized in English)

- Display

- Color LCD touch screen

- Host Power Supply

- 220V/50HZ (can be customized 110V/60HZ)

- Power

- 2000W

TM1300pro

Automatic Film Applicator

Wire rod Spreader, with heating function, servo motor, simple wire rod groove design, wire rod installation is simple, Smoothness hardening treatment aluminum alloy baseplate, wear resistance and scratch resistance.

FAQ

QViscosity 500-1000cps, Solid content 30-40%, thickness 1-10 microns. Area 230 ✖ 260 polyimide coated with epoxy glue, substrate is pet, which Film Applicator to use?

A

Wire Bar + Vacuum adsorption + Heating Automatic Film Applicator can be satisfied.

QHow does the heating coater achieve heating of the Spreader material?

A

The heating coater is baseplate heating, which heats the Spreader material through the built-in heating element, usually by controlling the temperature to achieve heating of the material.

QWhat are the advantages of the servo motor used in this Film Coater compared with traditional motors?

A

The advantage of using a servo motor is that it has higher running Stability, which can provide more accurate Spreader control and higher Spreader accuracy, and is suitable for laboratory applications that require high Spreader accuracy.

QHow to operate the touch screen control panel on the film scraper?

A

The touch screen control panel on the film scraper can adjust various parameters, such as Spreader speed, heating temperature, etc., through an intuitive interface and simple operation, which improves the convenience of operation and human-machine interaction.

QThe Spreader stage of the Film Coater is made of aluminum alloy. How important is this for the Spreader process?

A

Spreader table of Film Coater is made of aluminum alloy, which has the characteristics of high Hardness and strong abrasion resistance, which is conducive to improving the service life of Spreader table and Spreader mass.

QWhat is the importance of Temperature uniformity in Film Coaters? How to ensure Temperature uniformity?

A

Temperature uniformity is very important in the Film Coater, which affects the uniform heating of the intermediate coating material in the Spreader process and the mass of the Spreader result. Temperature uniformity can be guaranteed through the temperature Control system on the equipment.

Standard

TM1300pro

TM1300pro