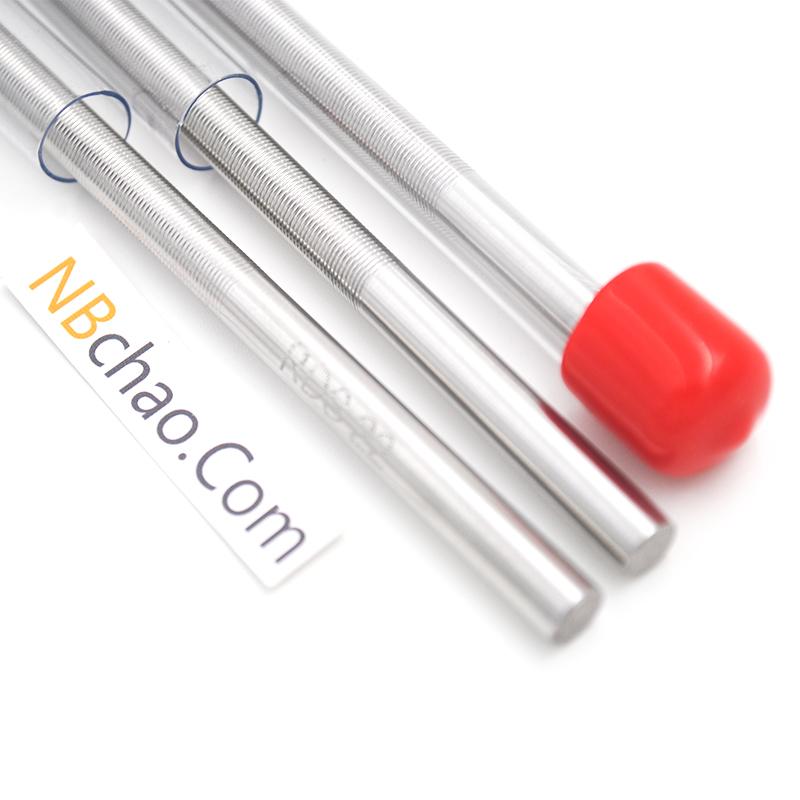

US RDS 3 #1/4 "inks coating bar film thickness 6.9μm rod diameter 6.35mm

SE-

RDS 3 #1/4 "wire-wound Applicator rod film thickness 6.9μm Wire diameter 0.08mm$ 156.00SE

RDS 3 #1/4 "wire-wound Applicator rod film thickness 6.9μm Wire diameter 0.08mm$ 156.00SE -

UK RK KHC.11.1 long coating rod WFT 6μm yellow rubber head No. 1 rod$ 168.00SE

UK RK KHC.11.1 long coating rod WFT 6μm yellow rubber head No. 1 rod$ 168.00SE -

UK RK KHC.10.1 short coating rod WFT 6μm yellow rubber head No. 1 rod$ 153.00SE

UK RK KHC.10.1 short coating rod WFT 6μm yellow rubber head No. 1 rod$ 153.00SE -

Japan OSP-08/400 stainless steel coating bar WFT 8μm length 400mm$ 173.00SE

Japan OSP-08/400 stainless steel coating bar WFT 8μm length 400mm$ 173.00SE -

RDS 3 #3/8 "No. 3 Molded Applicator rod 6.9μm Spreader rod$ 162.00SE

RDS 3 #3/8 "No. 3 Molded Applicator rod 6.9μm Spreader rod$ 162.00SE

RDS 3# 1/4 Applicator rod 1/4SPEC

RDS 3# 1/4 Applicator rod 1/4Details

RDS 3# 1/4 Applicator rod 1/4Packing list

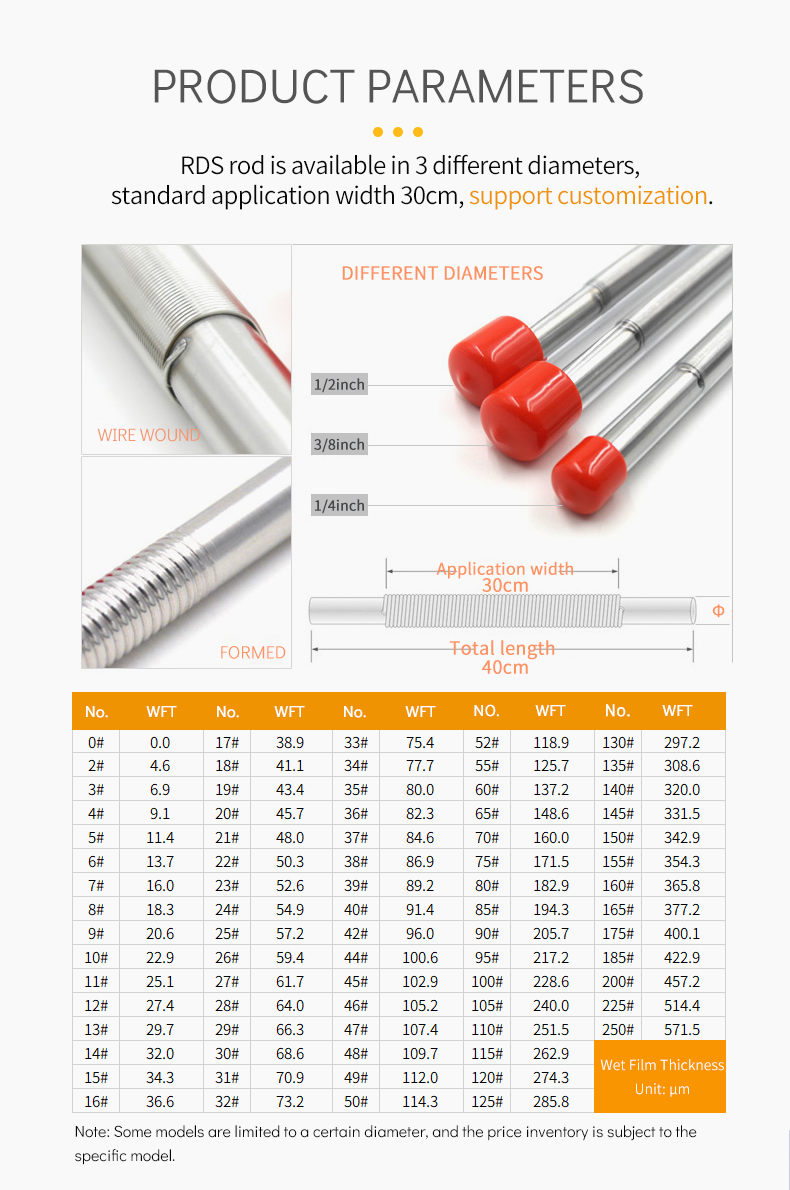

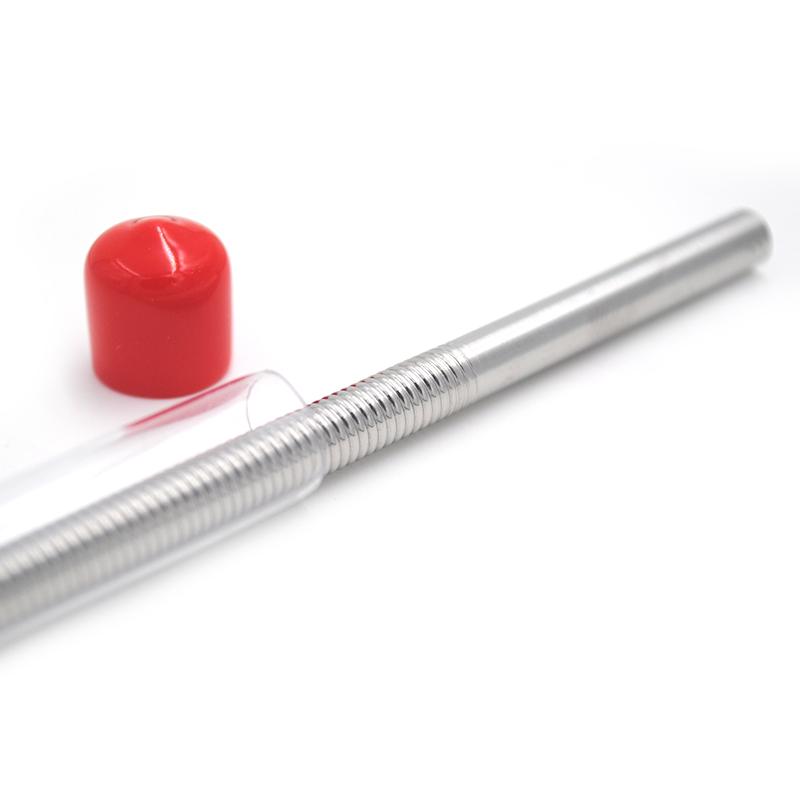

- SKU

- NB004573

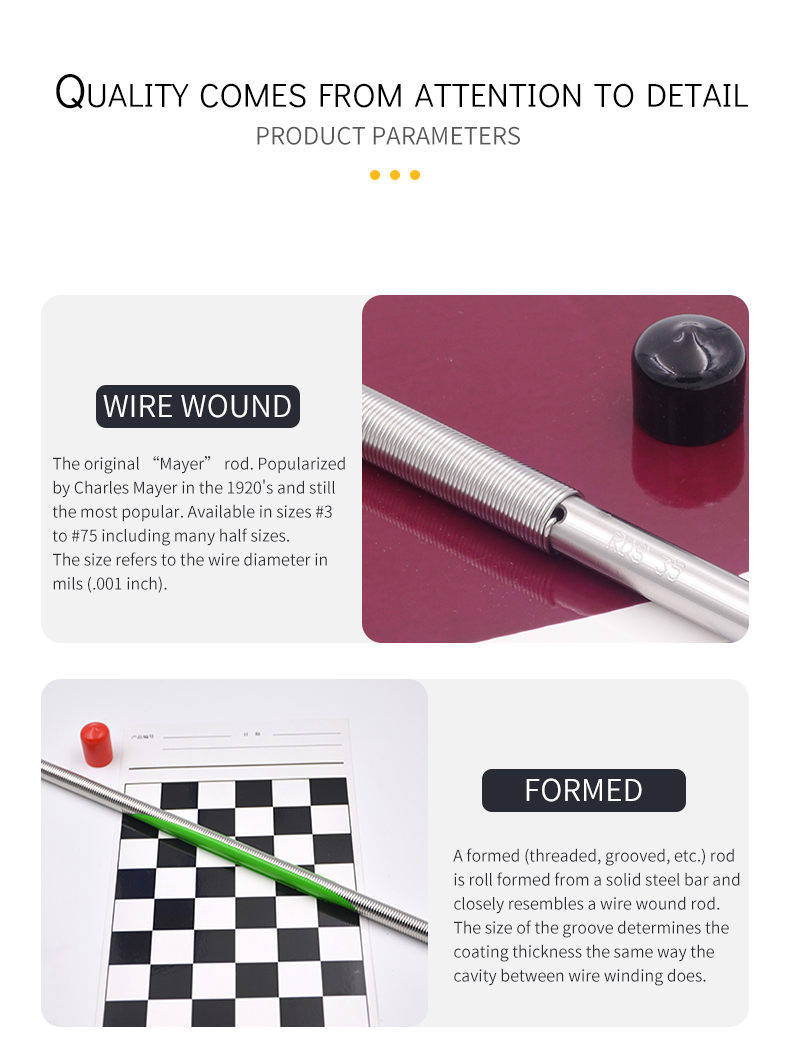

- Production process

- Formed

- WFT

- 6.9μm

- diameter

- 6.35mm

- Total length

- 400mm

- application width

- 300mm

- Grip Width

- 50+50mm

- material

- stainless steel

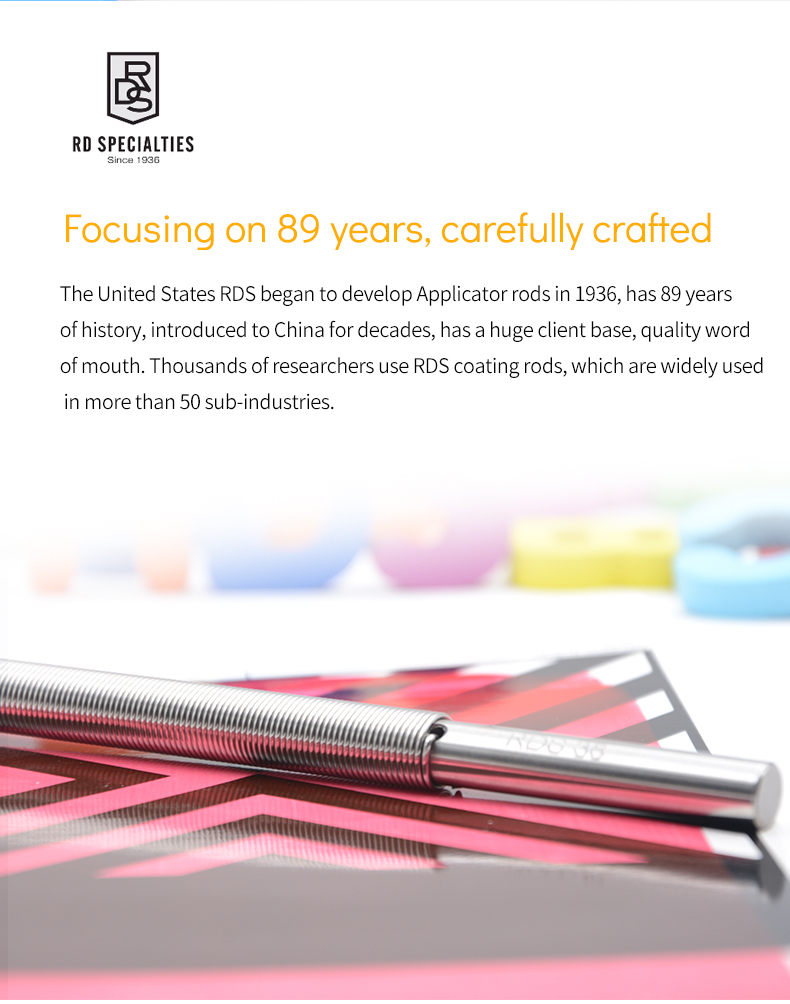

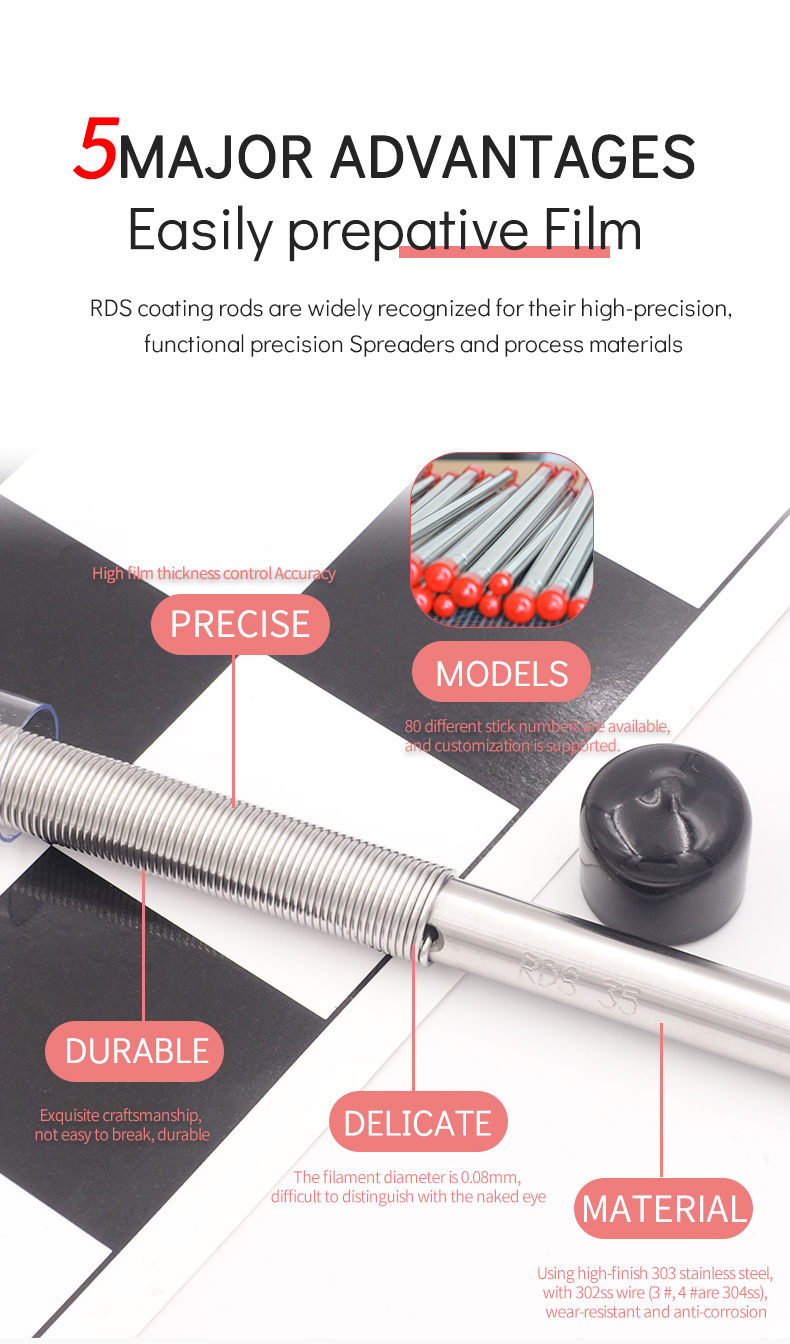

Some customers who bought RDS3 rods for the first time said that there is no steel wire on the rod~, hereby remind you that the diameter of RDS3 steel wire is 0.08mm, which is as thin as a human hair, and it is almost difficult to distinguish with the naked eye through seamless winding , viewing through a magnifying glass is recommended. Such reasons lead to returns and even damage the reputation of NBCHAO, it is really wronged!

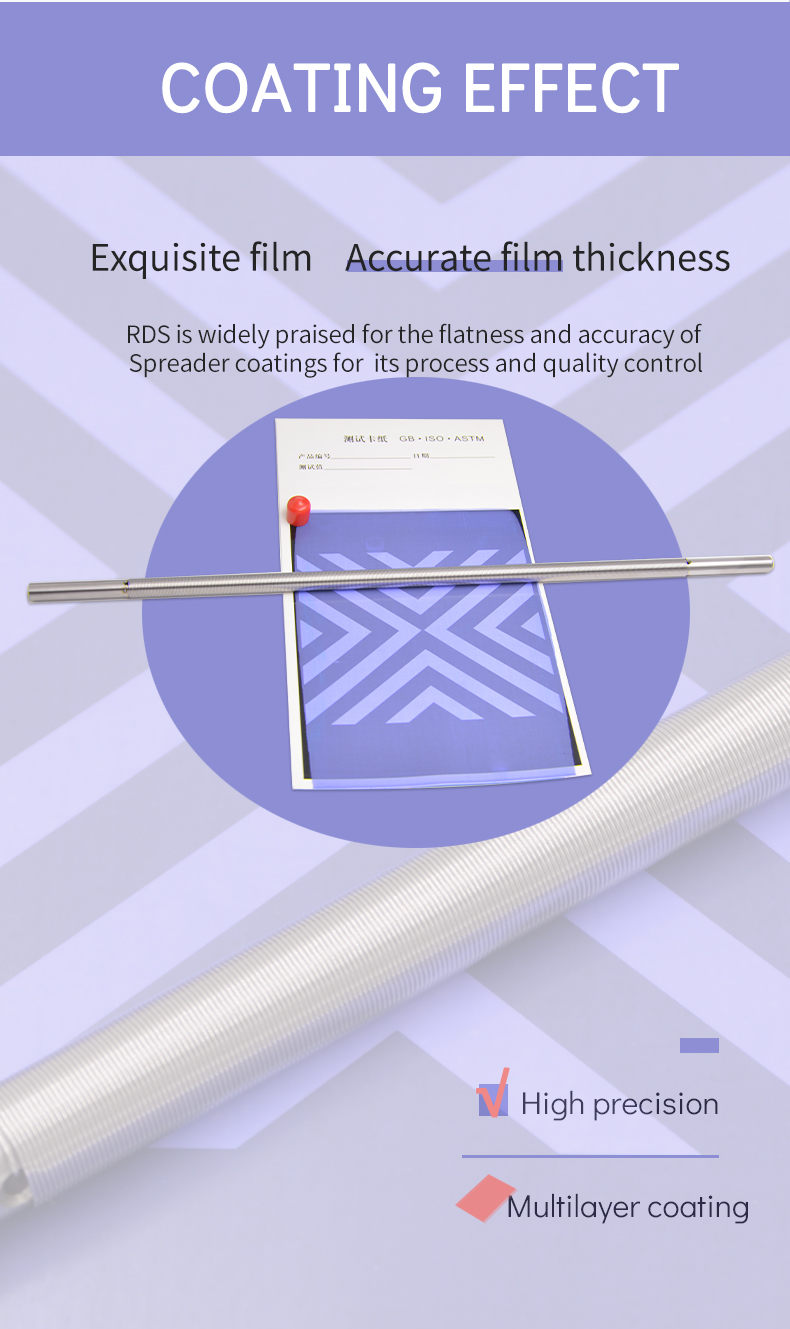

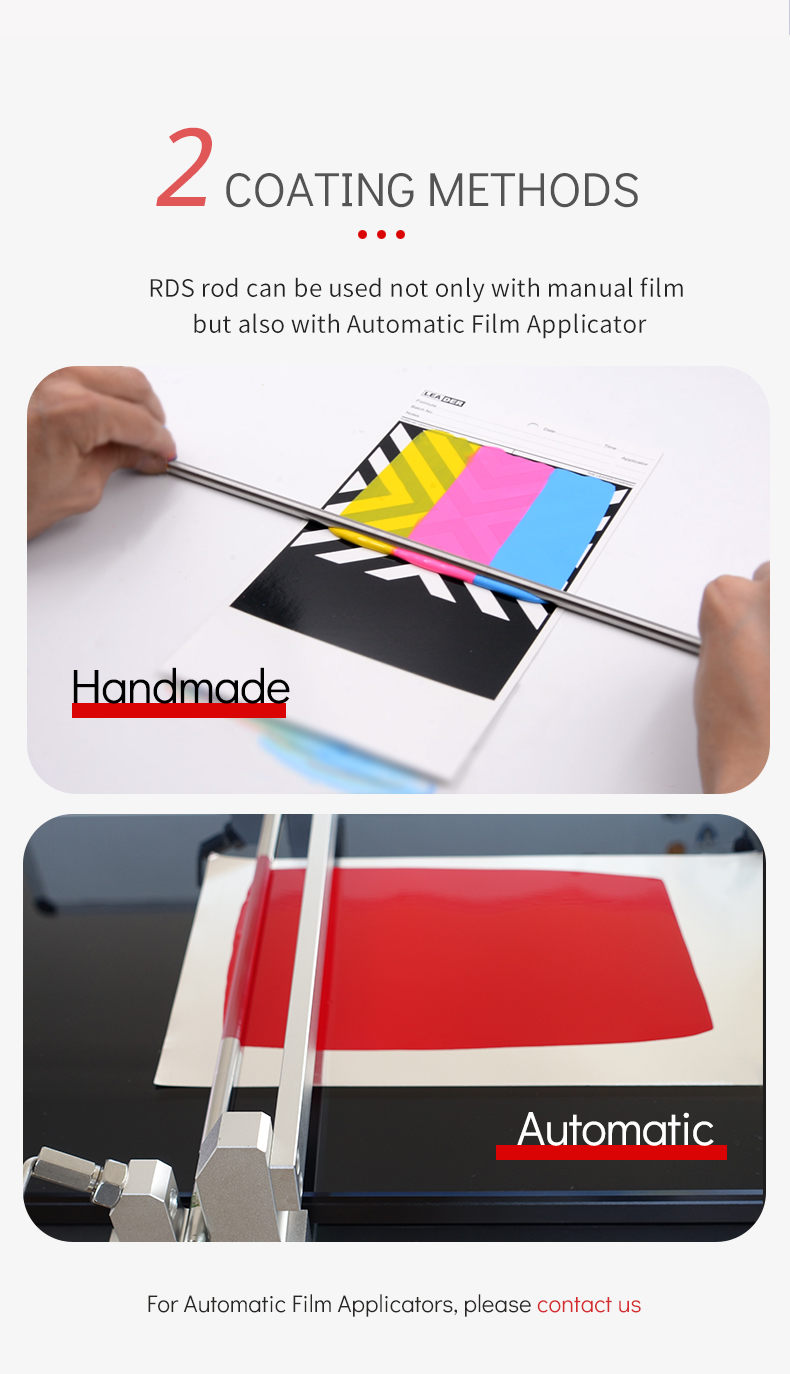

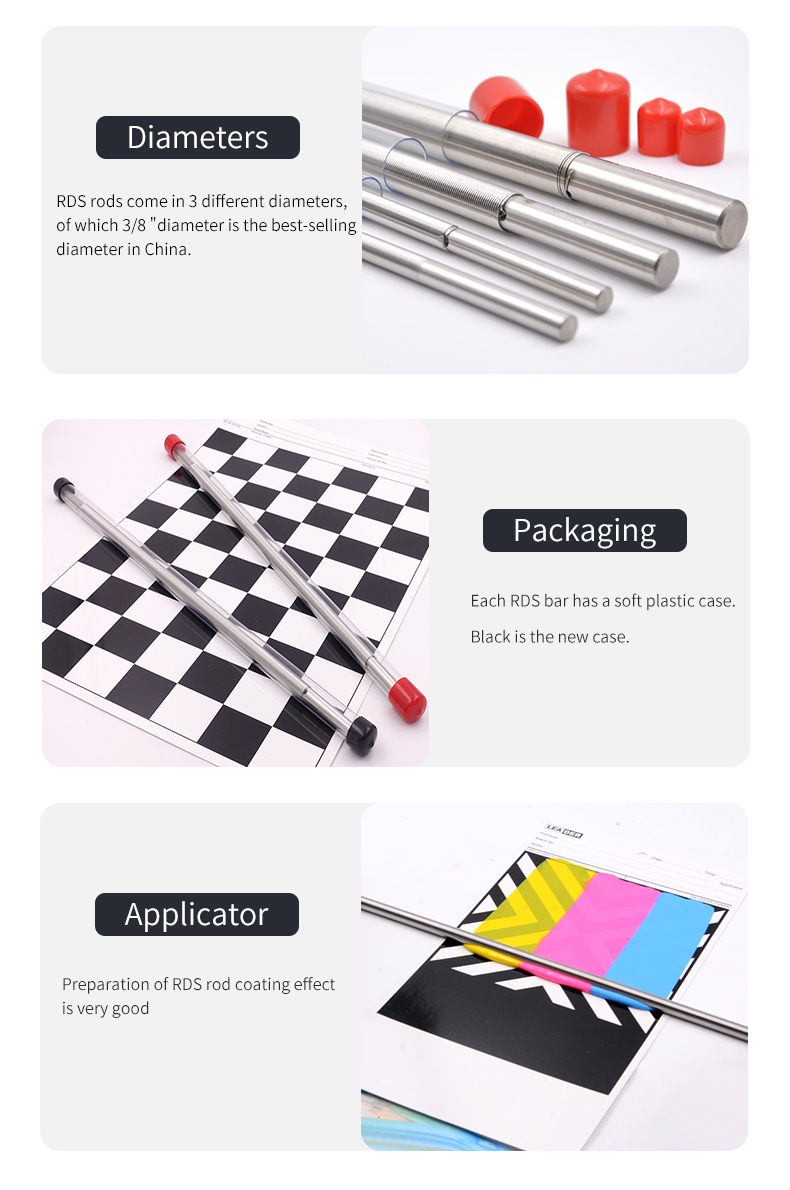

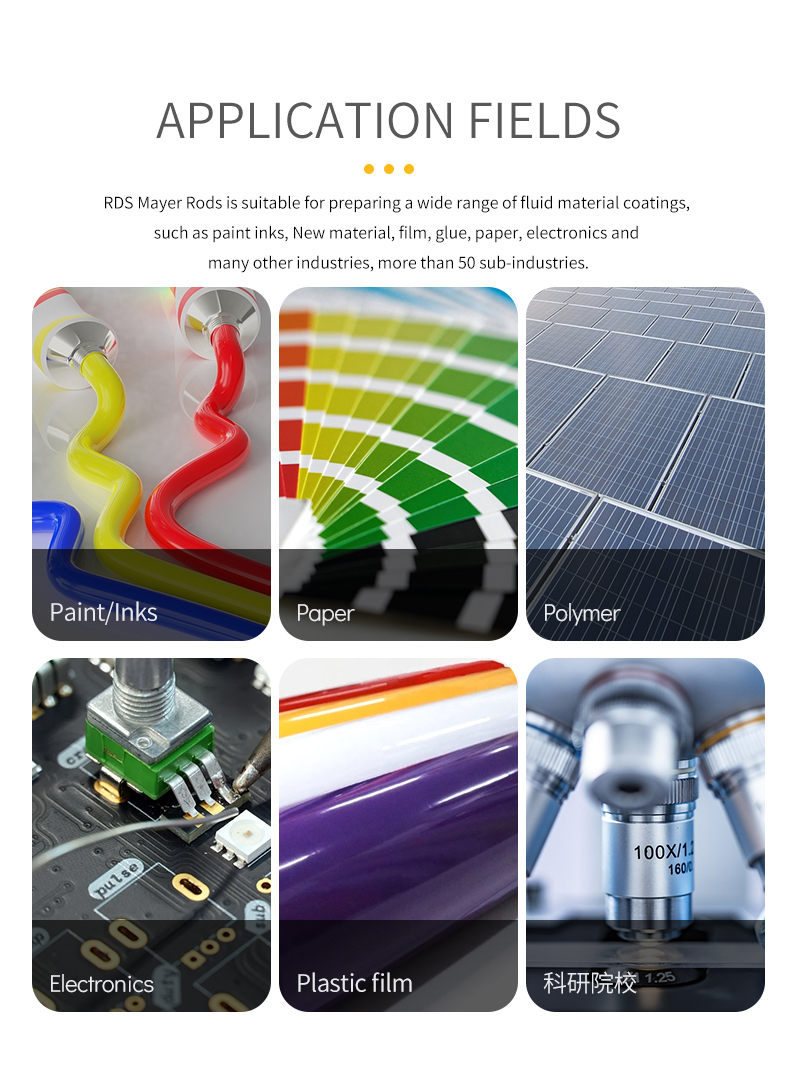

The RDS No. 3 wire Bar Coater is mainly used to prepare coatings of about 7 microns, which is suitable for precise film thickness (wet film) in coatings, inks, and most fluid industries. The No. 3 wire Bar Coater produced by RDS According to different diameters and processes, there are 4 models, namely 6.35mm diameter forming coating rod and wire-wound coating rod, 9.4mm diameter wire-wound coating rod and 12.7mm coating rod. In principle, the coating effect of rods with the same wet film thickness is consistent, but due to different diameters and process grooves, the amount of coating loss may be different. Chineseally, 9.4mm wire winding rods and 6.35mm forming rods are mostly used. The former is mainly a habit, while the latter is due to hardening of some coated substrates or concerns about broken wires caused by misuse, improper cleaning and bumps (probability 2 ‰, north and south tide statistics), users can choose by themselves.

- 1GB/T 1727-2021《General methods for preparation of coating films》

- 2GB/T 7044-2022《Colour carbon black》

- 3HG/T 5370-2018《Waterborne coatings for bicycles》

- 4HG/T 3951-2007《Water based colorants for architectural coatings》

- 5GB/T 13217.1-2020《Test method for colour and tinctorial strength of ink》

- 6HG/T 3948-2007《Hot Melt Adhesives for Sanitary napkin & Panty liner》

- 7GB/T 13217.1-2009《Test method for colour of liquid ink》

- 8GB/T 26461-2011《Gravure ink for paper》

- 9ASTM D823-2018《Paints, varnishes and related products of uniform thickness on the test board》

3# 1/4

3# 1/4