Wire rod + heating function, suitable for heating and drying samples, temperature control up to 180 ℃, Spreader countertop is made of hard aluminum alloy, Smoothness, Spreader uniform.

$2264.00/set

PromotionLoading...

Coupon

Model:

Similar products

-

China Heating Automatic Film Applicator TBJ-A2-XB Glue Coater bar type, with imported bar$ 1951.00SE

China Heating Automatic Film Applicator TBJ-A2-XB Glue Coater bar type, with imported bar$ 1951.00SE -

CHINA TBJ-A2-DJ1 Upper heating rod Coater Heating Film Applicator$ 2734.00SE

CHINA TBJ-A2-DJ1 Upper heating rod Coater Heating Film Applicator$ 2734.00SE -

HUINUO TM1100/02 Wire Bar Heating Film Applicator 260 ℃ High Temperature Coater$ 4770.00SE

HUINUO TM1100/02 Wire Bar Heating Film Applicator 260 ℃ High Temperature Coater$ 4770.00SE -

HUINUO TM1100 Wire Bar Heating Film Applicator 260 ℃ High Temperature Film Applicator$ 3674.00SE

HUINUO TM1100 Wire Bar Heating Film Applicator 260 ℃ High Temperature Film Applicator$ 3674.00SE -

China TBJ-A2 Heating Wire Rod Lab Film Applicator with Heating Scraping Machine$ 1794.00SE

China TBJ-A2 Heating Wire Rod Lab Film Applicator with Heating Scraping Machine$ 1794.00SE

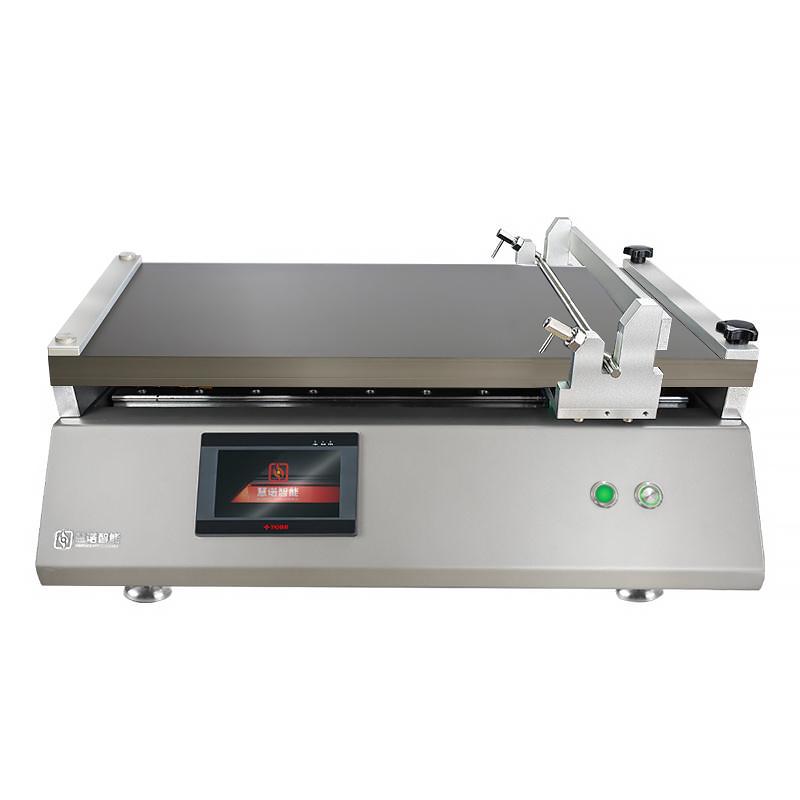

HuiNuo TM1100 Automatic Film ApplicatorSPEC

HuiNuo TM1100 Automatic Film ApplicatorDetails

HuiNuo TM1100 Automatic Film ApplicatorPacking list

- SKU

- NB045733

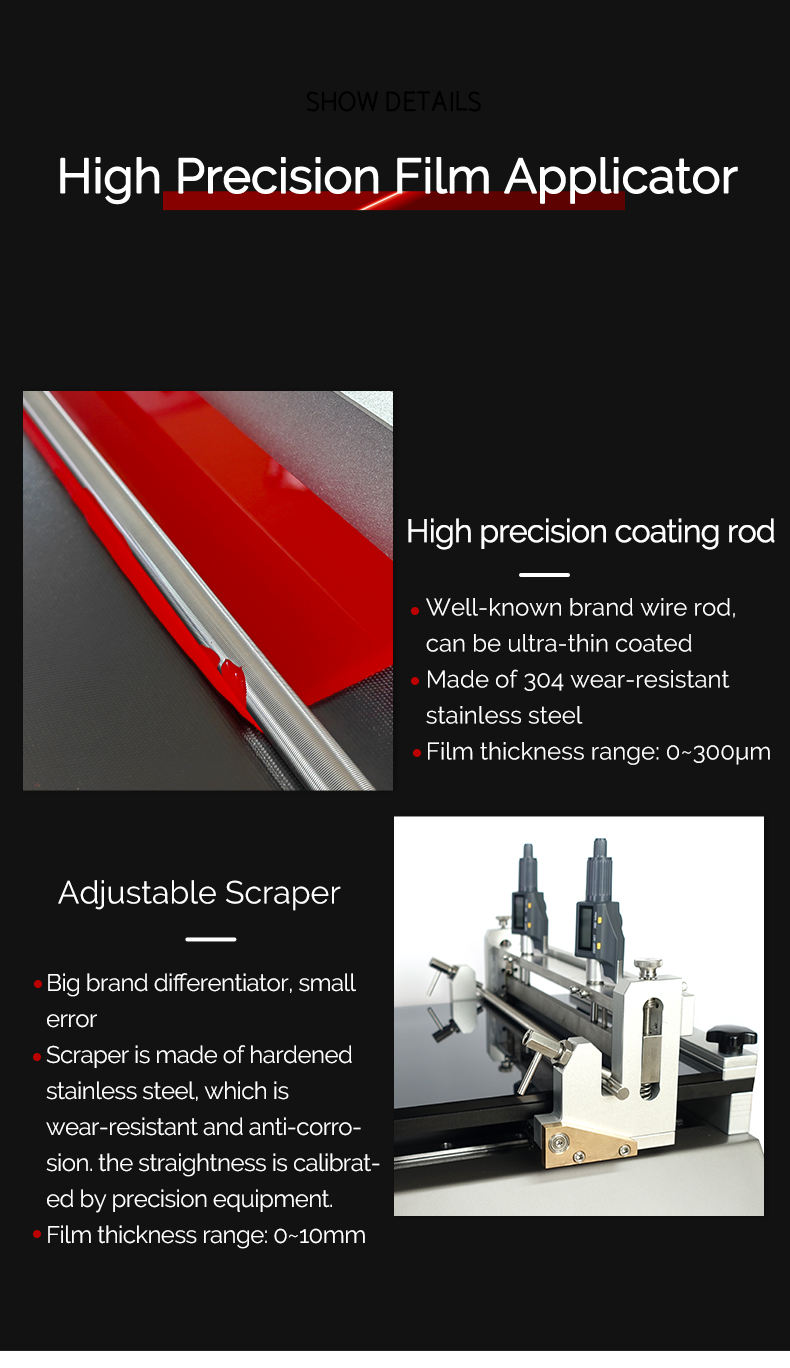

- Coating method

- Rod

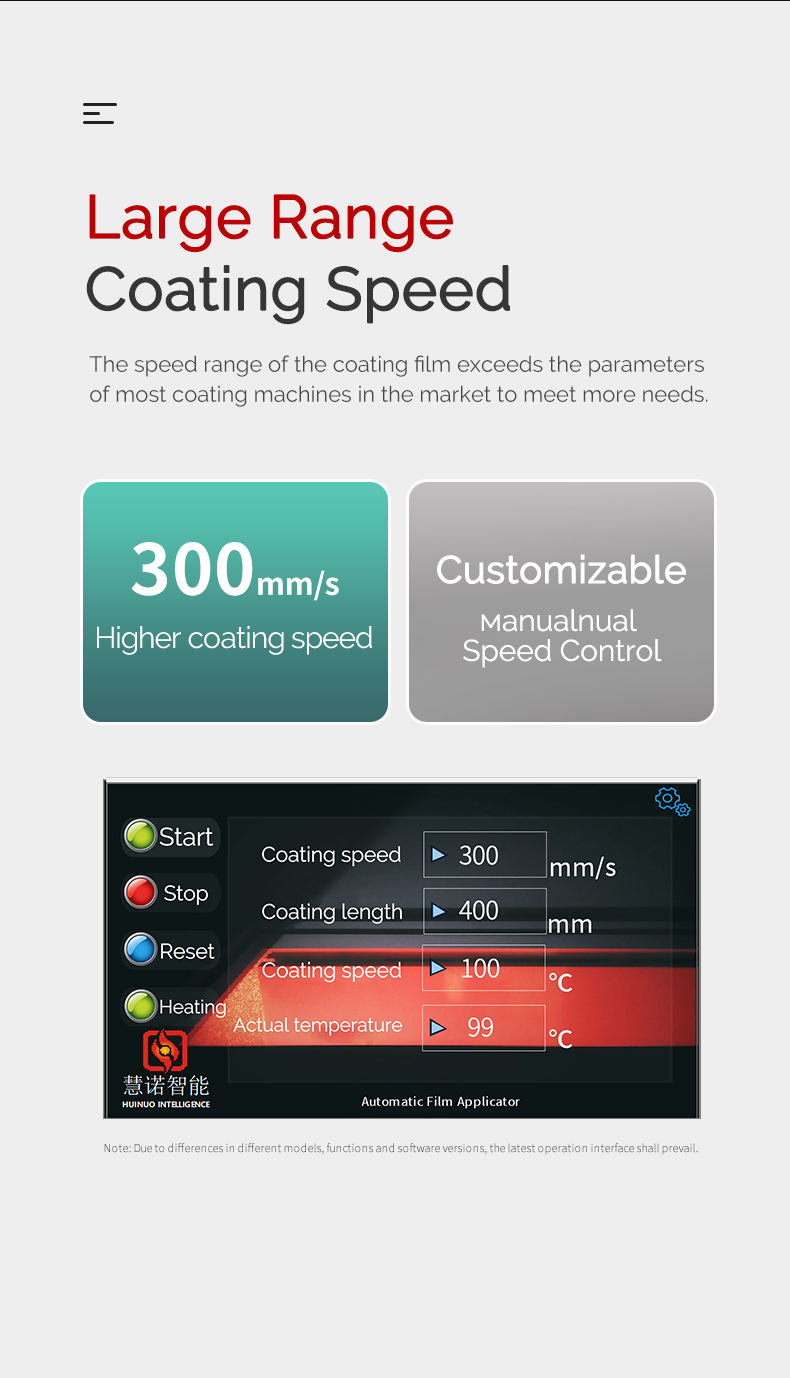

- Coating speed

- 1~ 300Mm/s stepless speed regulation (can be customized)

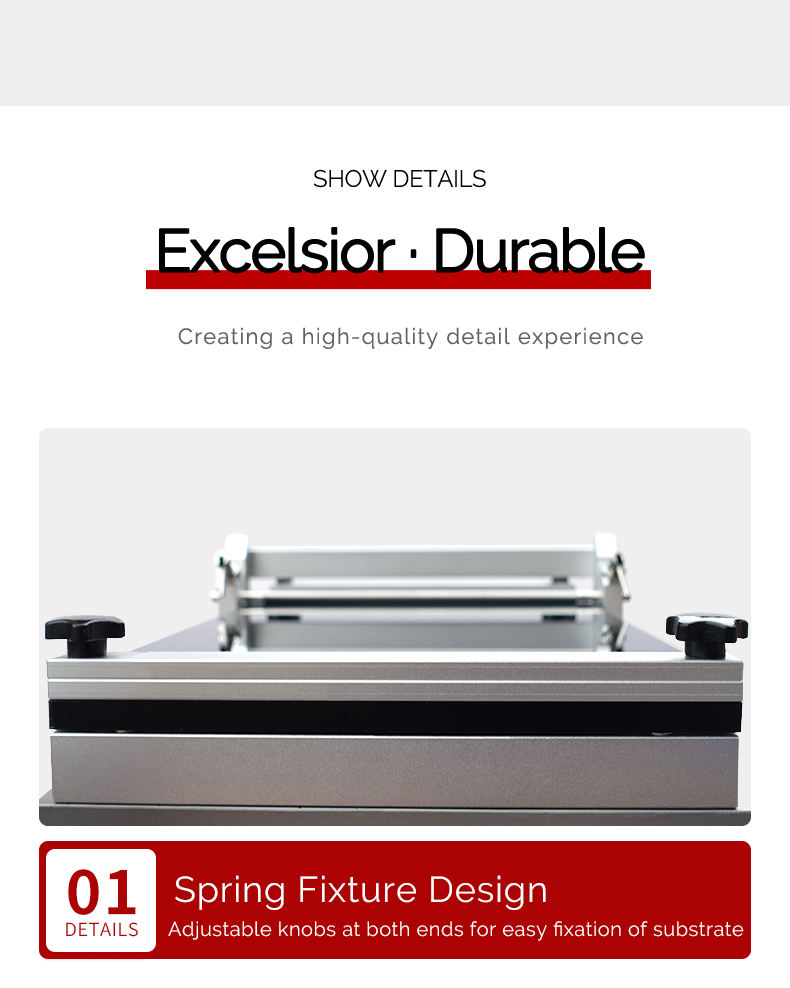

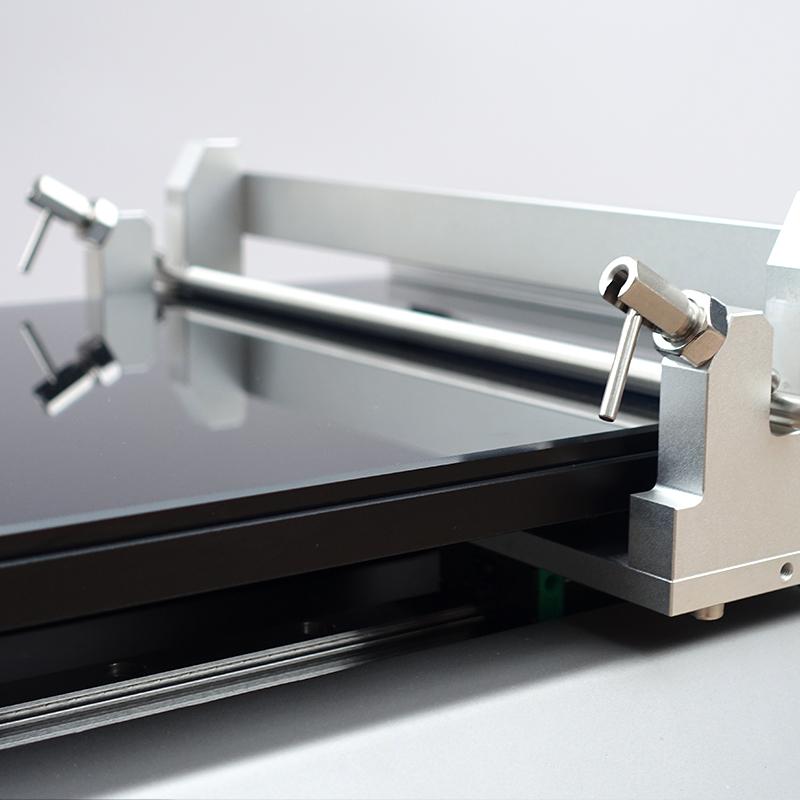

- Substrate clamping method

- fixture

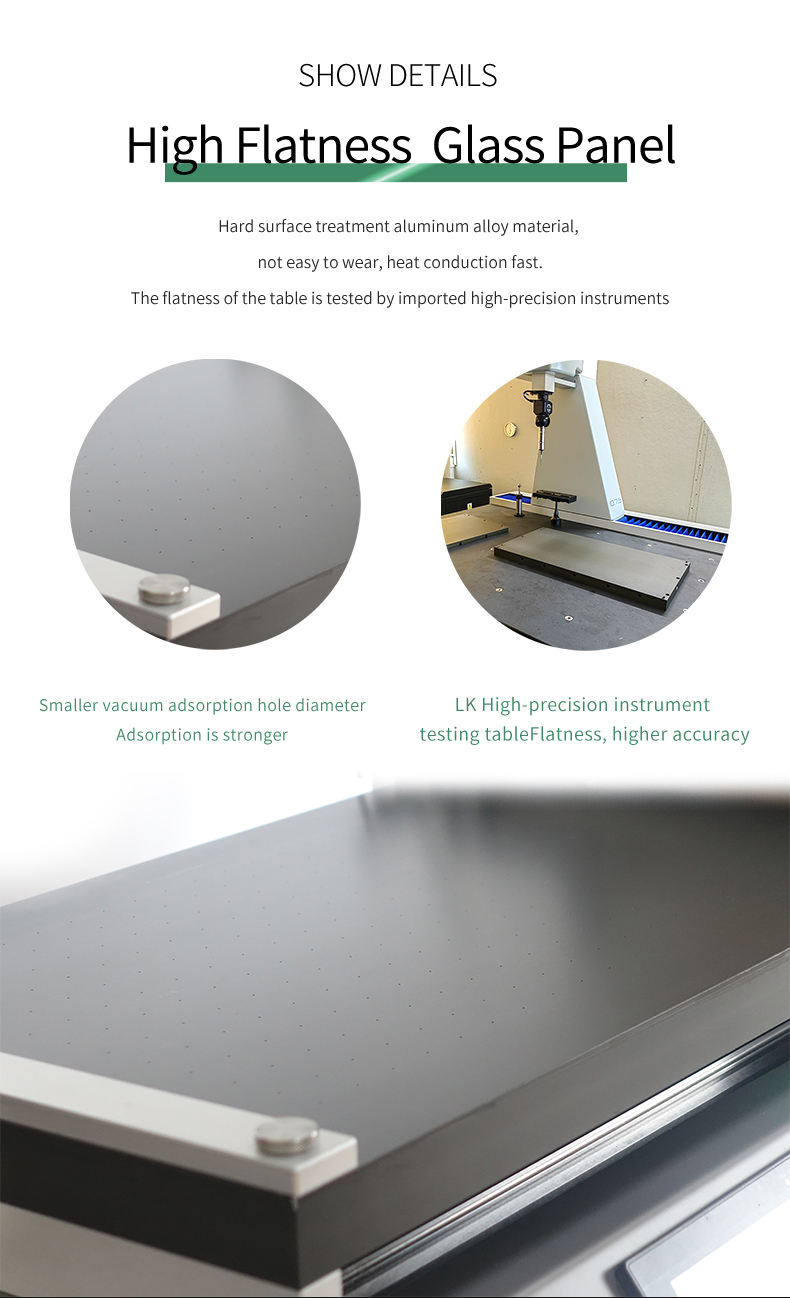

- Coating table material

- Surface hard treatment aluminum alloy

- Coating table size

- 600*300mm

- Effective coating Area

- 400 * 300Mm (can be customized)

- Mayer Rod Thickness Range

- Different bar numbers have different thicknesses, with high-precision imported bars

- Mayer Rod Accuracy

- ±0.001mm

- Power

- 1800w

- Heating mode

- Mica sheet heating (optional graphene heating, faster thermal conductivity)

- Heating Temperature range

- RT +~ 180 ℃ (higher temperature can be customized)

- Temperature Uniformity

- ±1℃

- Operating language

- Chinese (can be customized in English)

- Display

- Color LCD touch screen

- Host Power Supply

- 100V~220V/50~60HZ

- Dimension

- 658*438*400mm

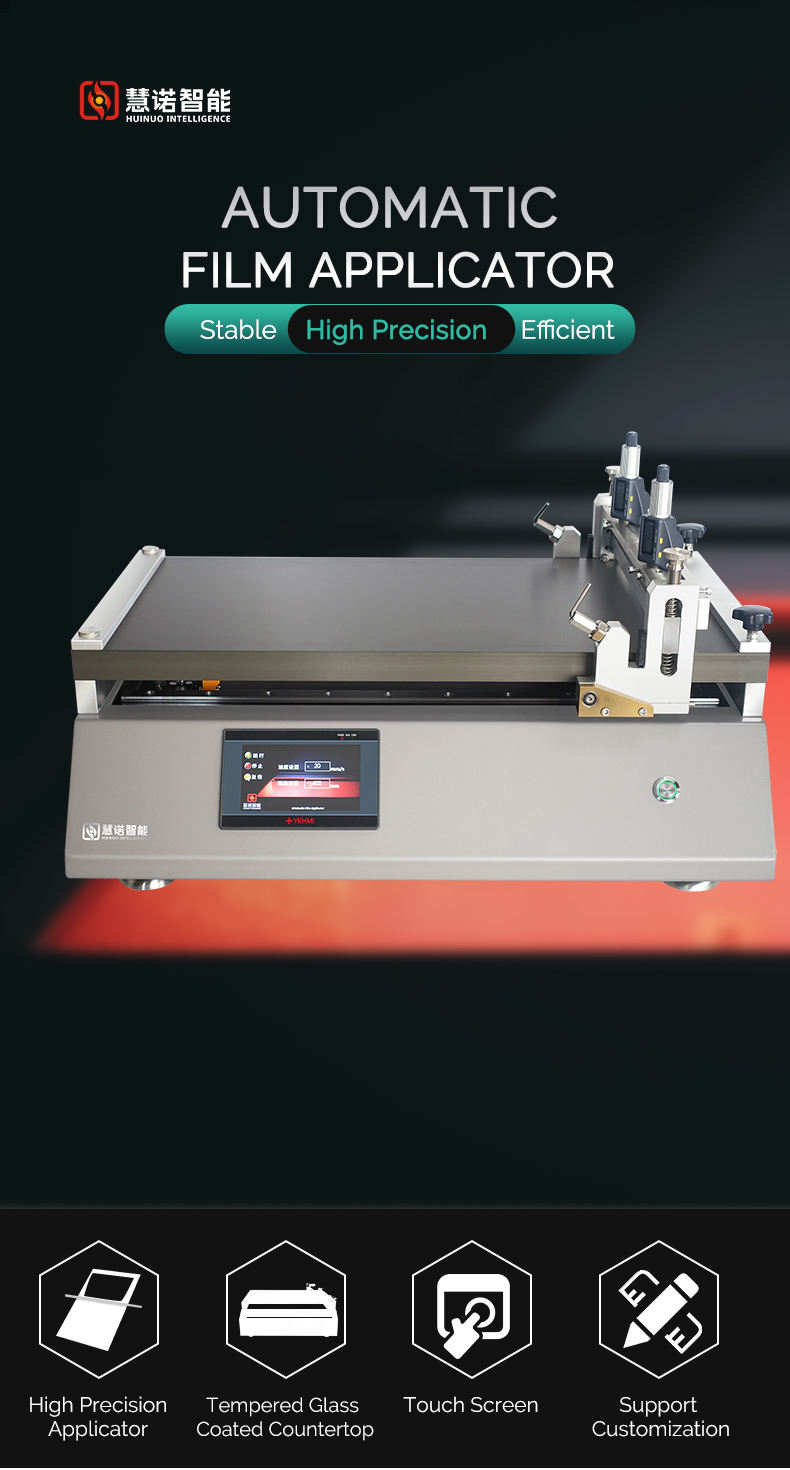

TM1100

Automatic Film Applicator

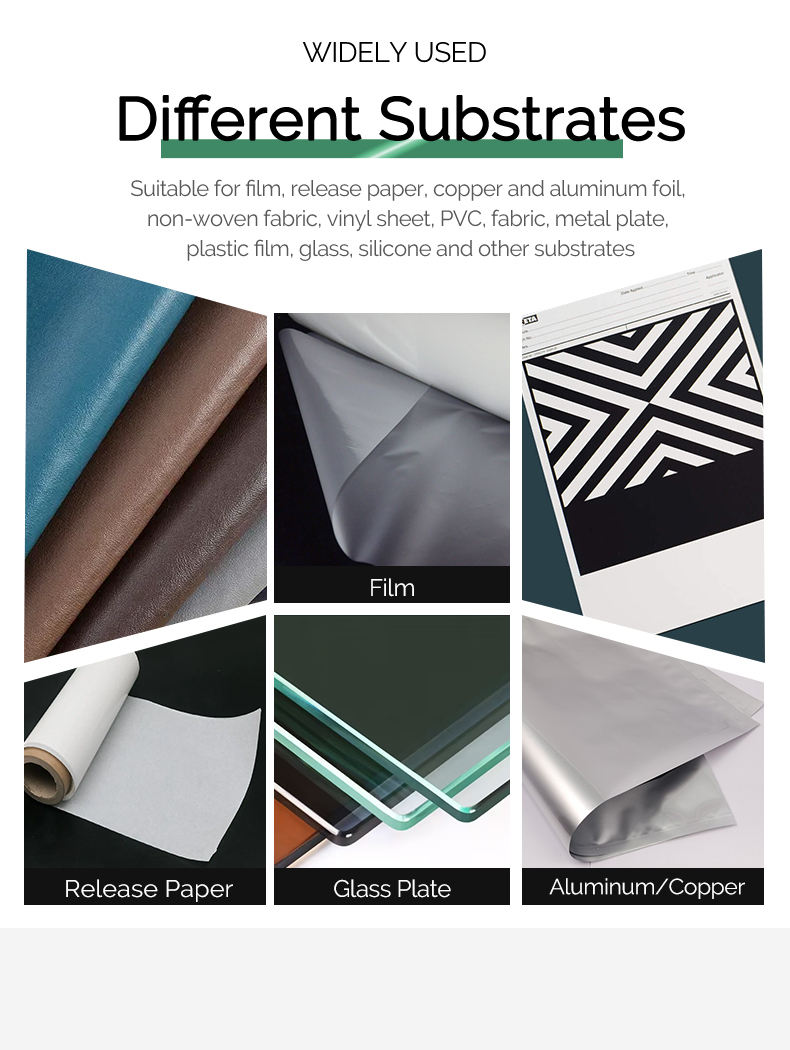

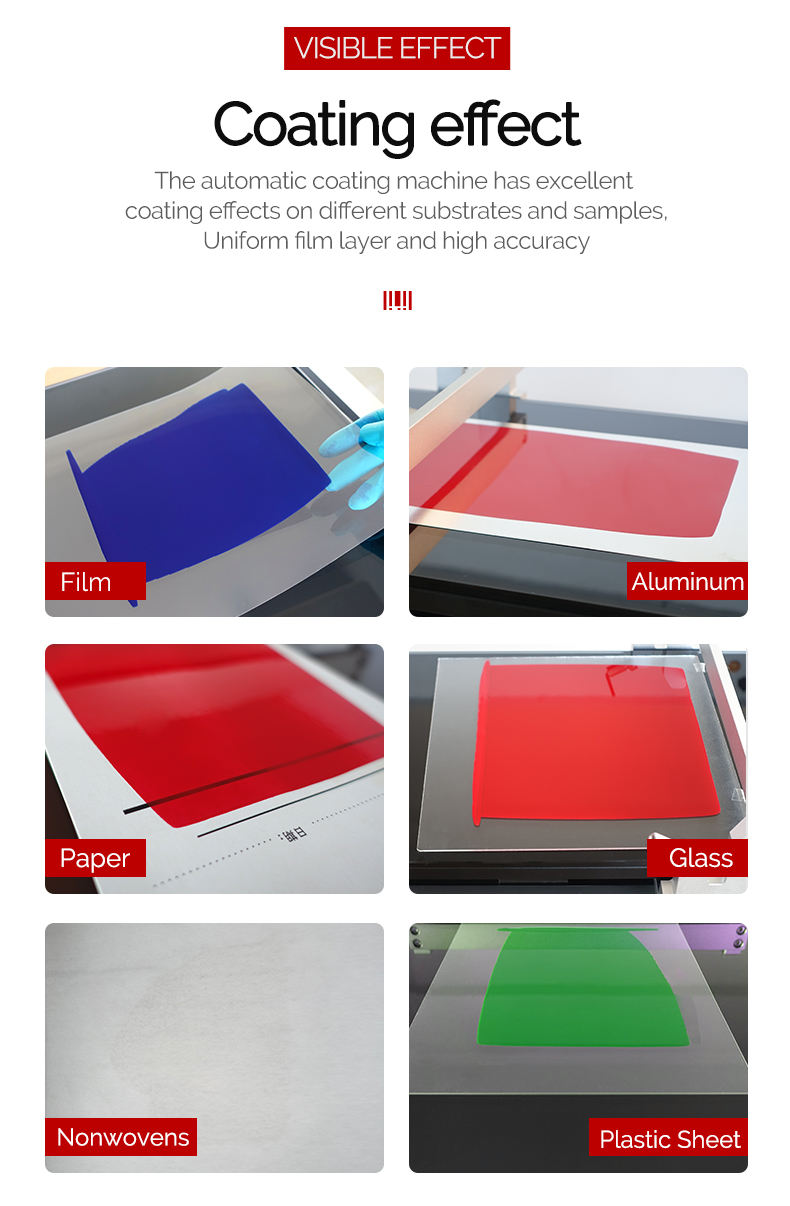

Wire rod + heating function, suitable for heating and drying samples, temperature control up to 180 ℃, Spreader countertop is made of hard aluminum alloy, Smoothness, Spreader uniform.

FAQ

QHello, I would like to consult the laboratory Automatic film applicator, with a thickness of about 1-10 microns, coated on stainless steel.

A

Can use wire rod heating coater, support heating drying, standard imported high-precision wire rod.

QHow to adjust the Temperature range of the heating coater?

A

Temperature range adjustment of the heating coater can be achieved by the temperature controller on the device, through the touch screen input parameters to adjust the set temperature.

QIn the non-woven fabric coating glue, film thickness 0.045~ 0.055mm, which Film Applicator?

A

Use Wire Bar + Heating Function Automatic Film Applicator.

QWhat is a Wire Spreader? What are the advantages over Miscellaneous Spreaders?

A

Wire Spreader is one of the Spreader methods, suitable for high-precision film needs. The Wire Spreader Installation method of this Automatic Film Applicator improves the efficiency of Spreader and is easy to clean.

QWhat is the heating Temperature range of the heating coater? How does this affect the Spreader of different materials?

A

The heating Temperature range of this heating coater is from room temperature to 180 ° C. The setting of this range can meet the needs of different material Spreaders, improving the flexibility and applicability of Spreaders.

QWhat are the differences in Spreader results between heating coaters and regular coaters?

A

Compared with ordinary coaters in terms of Spreader results, the heating function can better control the viscosity and flowability of the Spreader material, resulting in more uniform and better mass Spreader results.

QWhat laboratory applications is this heating coater suitable for?

A

This heating coater is suitable for various film prepative work in the laboratory, especially in the laboratory of New material, hot-melt adhesive, glue, Resin and other fields.

Standard

TM1100

TM1100