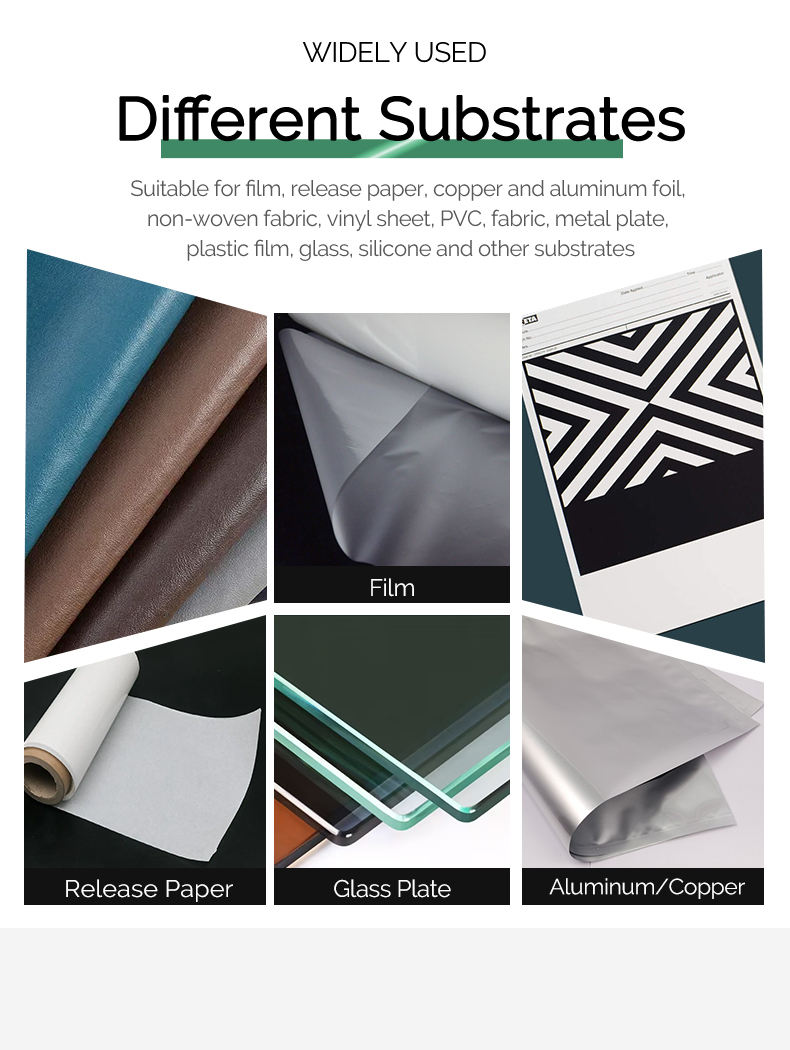

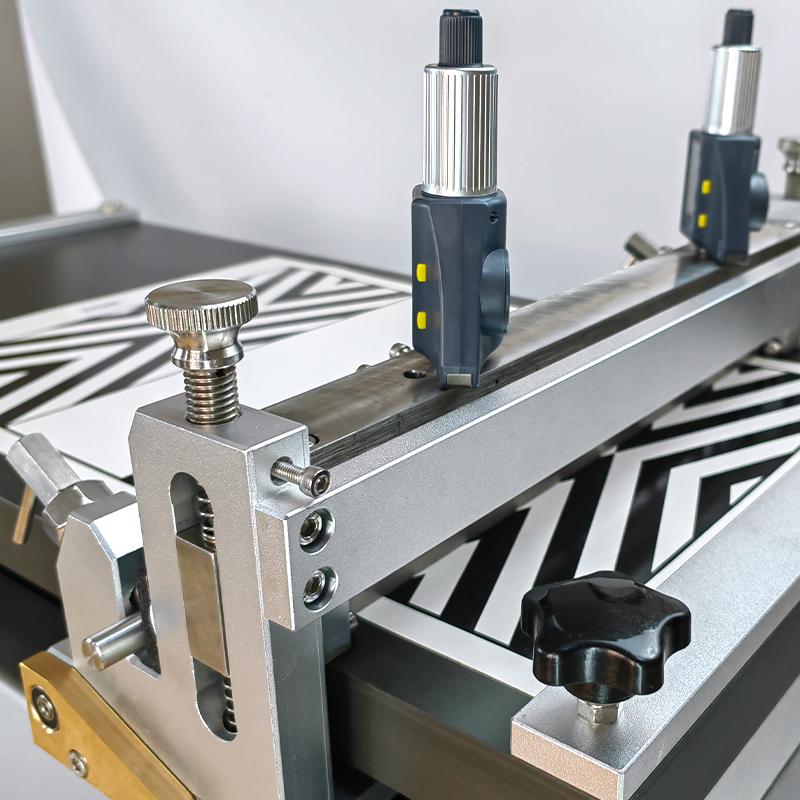

Drawdown blade + Vacuum chuck function, clamshell Drawdown blade design, easy and fast cleaning, corrosion resistance and wear resistance Drawdown blade material, effective coating area 400 * 300mm, suitable for high viscosity sample scraping.

$3830.00/set

PromotionLoading...

Coupon

Model:

Similar products

-

China TBJ-X1-DJ4 Removable Drawdown blade Vacuum chuck Film Applicator Laboratory Draw-Down Applicator$ 3047.00SE

China TBJ-X1-DJ4 Removable Drawdown blade Vacuum chuck Film Applicator Laboratory Draw-Down Applicator$ 3047.00SE -

China Experimental Drawdown blade Coater TBJ-GDO Vacuum chuck Film Coater$ 2421.00SE

China Experimental Drawdown blade Coater TBJ-GDO Vacuum chuck Film Coater$ 2421.00SE -

China TBJ-X1 Vacuum chuck Drawdown blade Film Applicator Lithium battery small Coater$ 2812.00SE

China TBJ-X1 Vacuum chuck Drawdown blade Film Applicator Lithium battery small Coater$ 2812.00SE -

China TBJ-X1-DJ2 Experimental Drawdown blade Coater automatic feeding + Vacuum chuck + Drawdown blade Multifunctional Film Applicator$ 5083.00SE

China TBJ-X1-DJ2 Experimental Drawdown blade Coater automatic feeding + Vacuum chuck + Drawdown blade Multifunctional Film Applicator$ 5083.00SE -

China TBJ-X1 Vacuum chuck Drawdown blade Lab Film Applicator Size 330 * 400mm$ 2984.00SE

China TBJ-X1 Vacuum chuck Drawdown blade Lab Film Applicator Size 330 * 400mm$ 2984.00SE

HuiNuo TM2200 Automatic Film ApplicatorSPEC

HuiNuo TM2200 Automatic Film ApplicatorDetails

HuiNuo TM2200 Automatic Film ApplicatorPacking list

- SKU

- NB045736

- Coating Method

- Drawdown blade Spreader

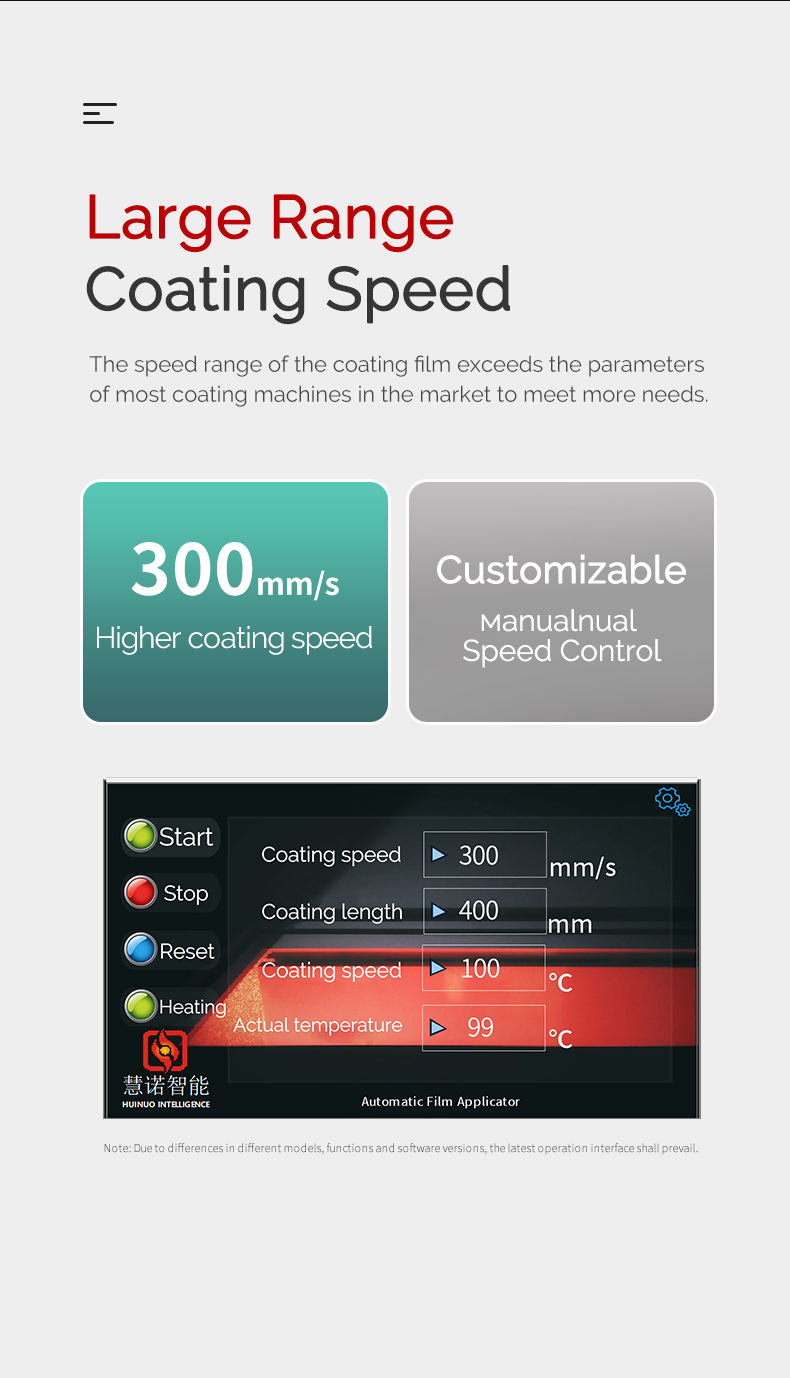

- Coating Speed

- 1~ 300Mm/s stepless speed regulation (can be customized)

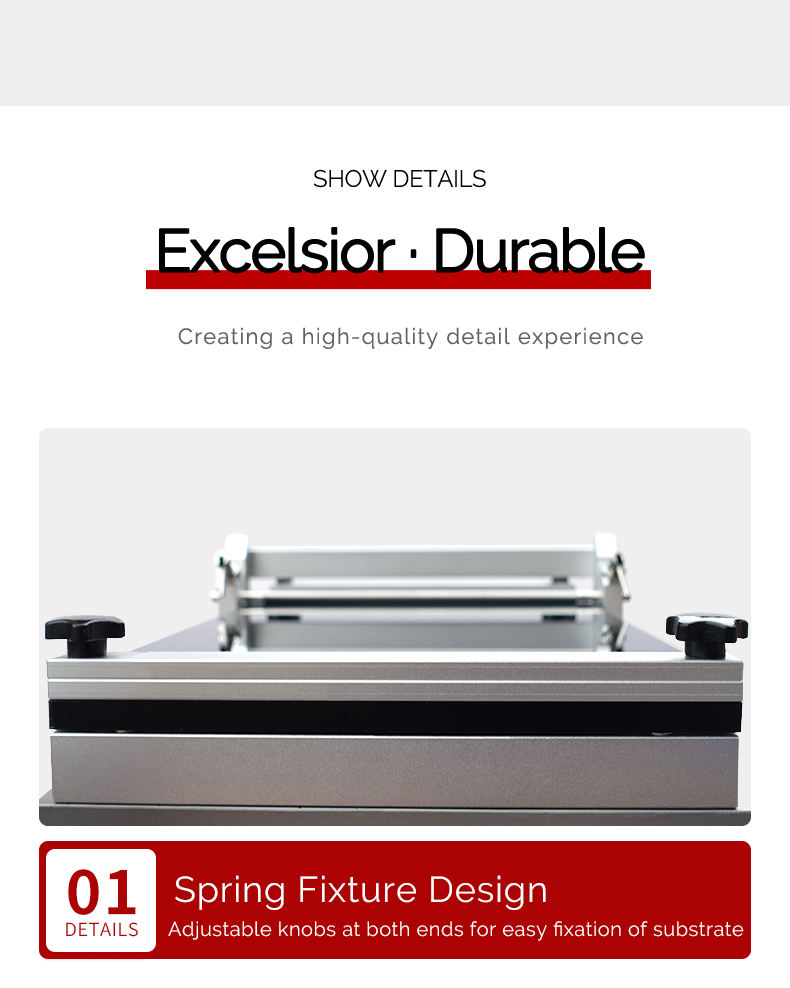

- Substrate clamping method

- Vacuum chuck + fixture

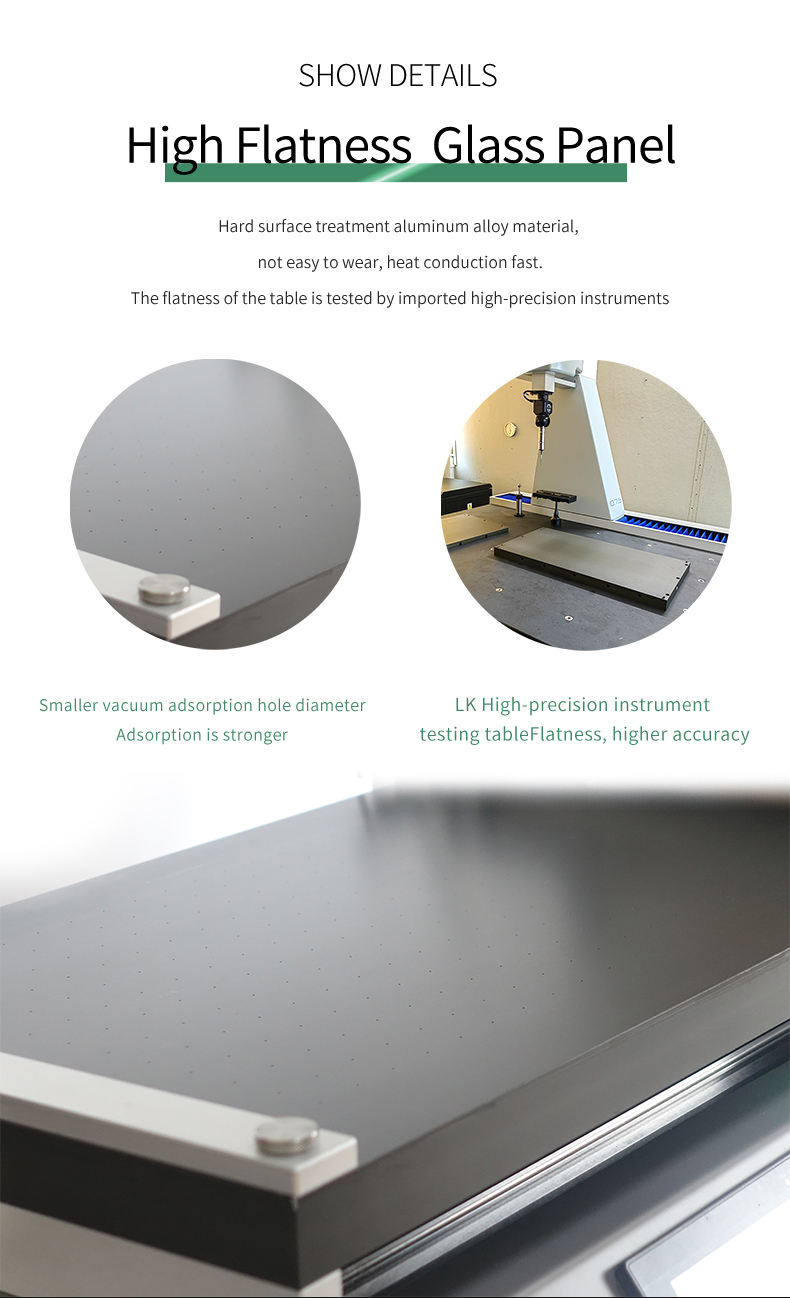

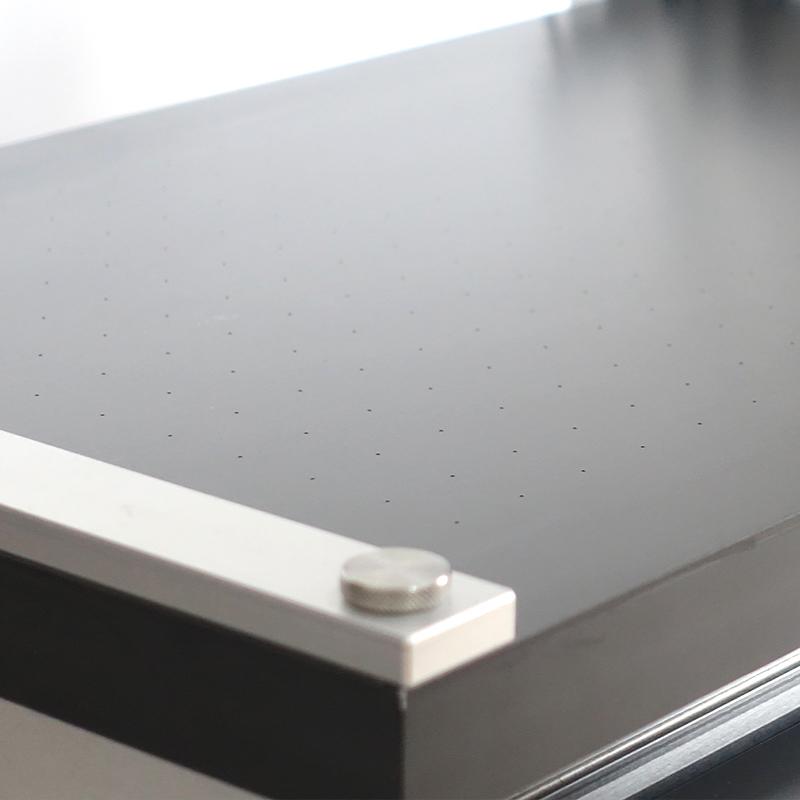

- Coating table material

- Surface hard treatment aluminum alloy

- Coating table size

- 600*300mm

- Effective coating Area

- 400 * 300Mm (can be customized)

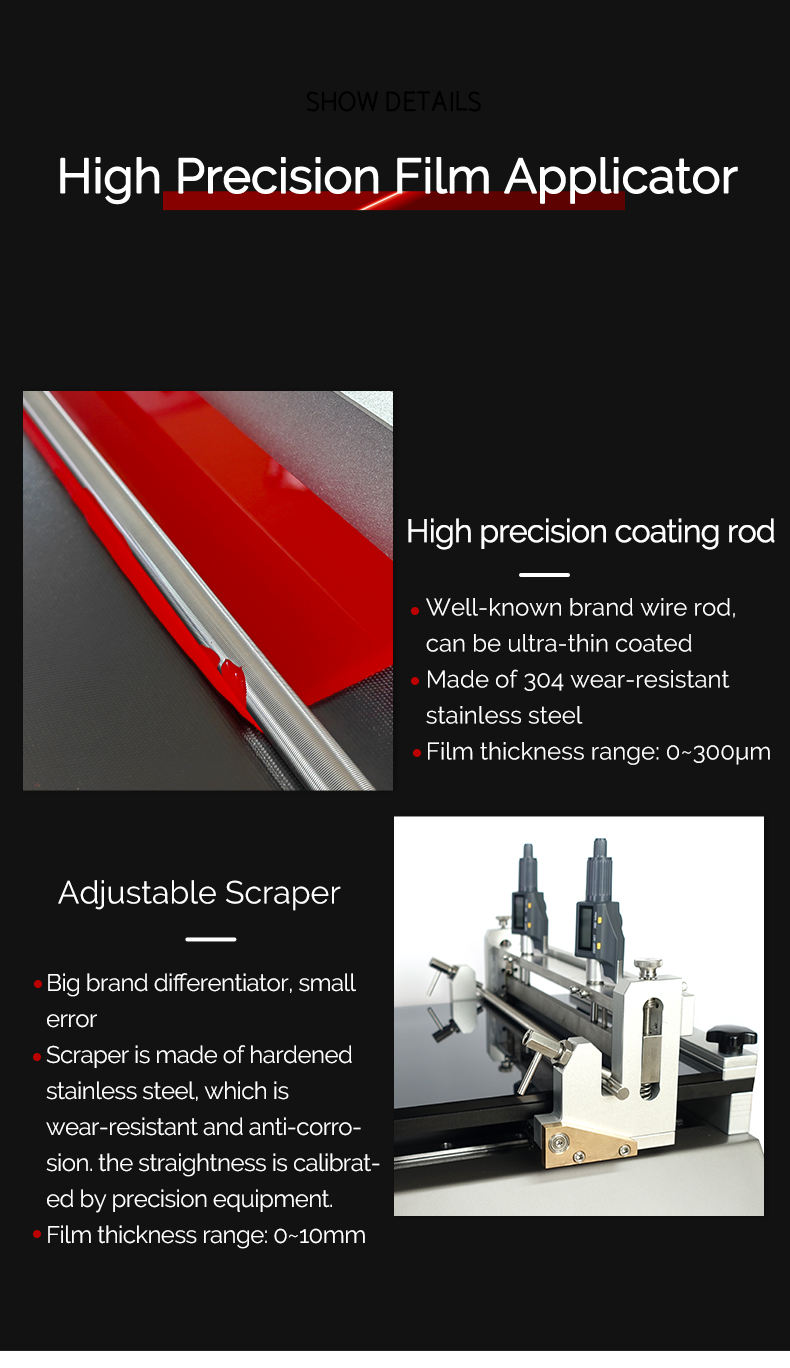

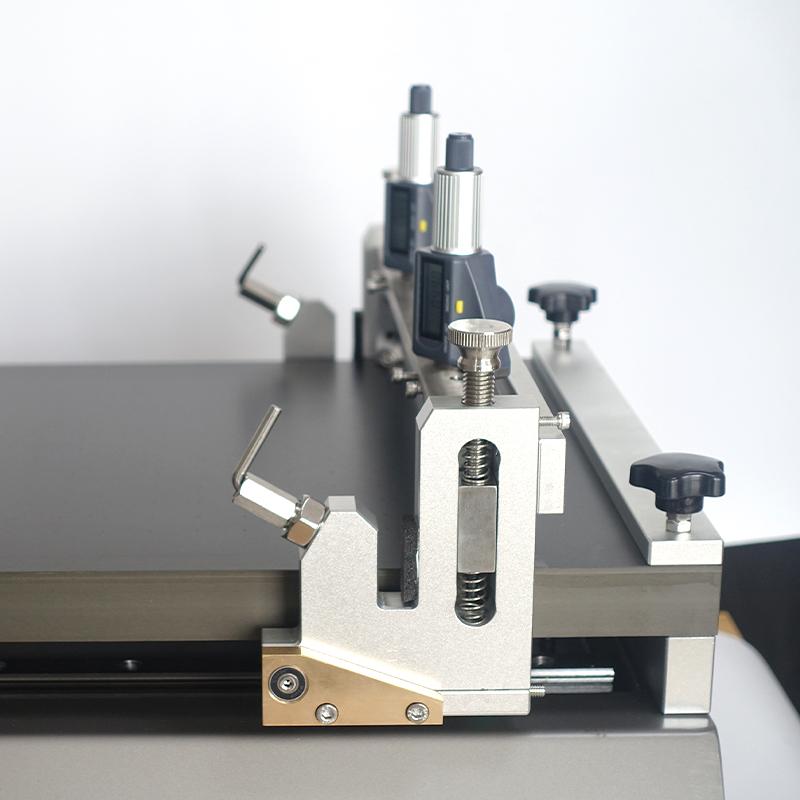

- Drawdown blade Coating thickness range

- 0~ 10Mm (clamshell design is easy to clean)

- Drawdown blade material

- Die steel

- Drawdown blade application width

- 300mm

- Drawdown blade Spreader Accuracy

- ±0.003mm

- Vacuum chuck size

- 480 * 260Mm (can be customized)

- Vacuum Aperture

- Φ0.8mm

- Vacuum hole pitch

- 20*20mm

- Pumping Speed

- 5.4m3/h

- Ultimate Vacuum

- 50KPa

- Vacuum Pump Power

- 180W

- Vacuum pump Weight

- 7.1kg

- Operating language

- Chinese (can be customized in English)

- Display

- Color LCD touch screen

- Host Power Supply

- 100V~220V/50~60HZ

- Power

- 400w

- Dimension

- 658*438*400mm

TM2200

Automatic Film Applicator

Drawdown blade + Vacuum chuck function, clamshell Drawdown blade design, easy and fast cleaning, corrosion resistance and wear resistance Drawdown blade material, effective coating area 400 * 300mm, suitable for high viscosity sample scraping.

FAQ

QI want to prepare lithium battery electrode samples in the laboratory. Which Film Applicator is more suitable?

A

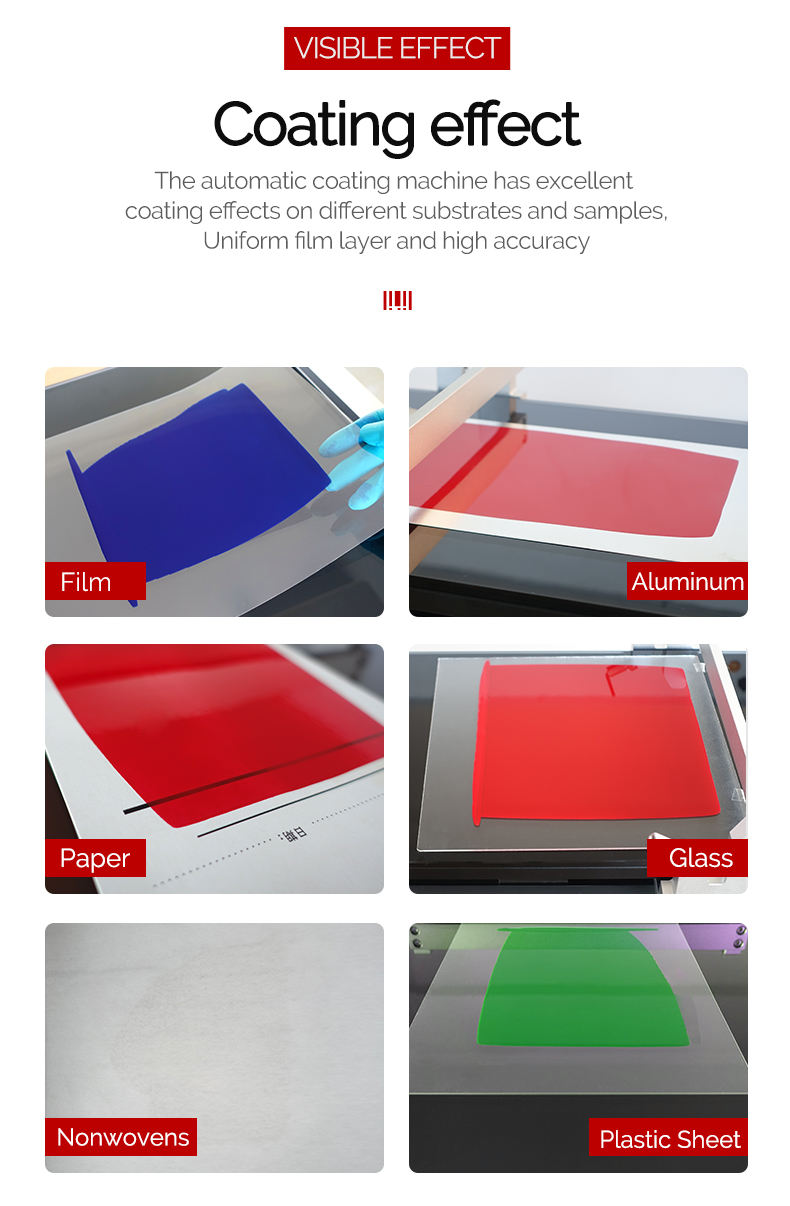

HuiNuo TM2200 Automatic Film Applicator adopts drawdown blade coating method, Spreader accuracy up to +/- 0.003mm, can ensure pole piece Spreader uniformity; with Vacuum chuck function, can firmly fix aluminum foil copper foil substrate, avoid Spreader process displacement; Spreader speed 1~ 300mm/s stepless adjustable, can meet the Spreader requirements of different slurry characteristics.

QWhat are the features of this Film Applicator in terms of operation and accuracy?

A

TM2200 is very convenient to operate, using touch screen control, application length and speed can be freely adjusted. In terms of accuracy, use big brand differential regulator to control film thickness, cooperate with hard treatment aluminum alloy countertop to ensure Smoothness, Vacuum chuck + fixture double fixing method to ensure Spreader Stability, especially suitable for scientific research scenarios that require high Repeatability experiments.

QI want to make film samples of lithium battery materials in the laboratory, is that okay?

A

Yes, this device is specially designed for high-precision film in the laboratory, supports film sample preparation of lithium battery materials, has Vacuum chuck function to ensure that the substrate is flat, Spreader accuracy is up to +/- 0.003mm, which can meet the strict requirements of lithium battery materials for film uniformity.

QI need the Film Applicator to have precise control of film thickness and stable Spreader.

A

HuiNuo TM2200 Automatic Film Applicator is recommended. It is equipped with a big brand differential regulator with high film thickness control accuracy; coating speed 1~ 300mm/s stepless speed regulation, Vacuum chuck + fixture fixed substrate to ensure stable Spreader process, thickness range 0~ 10mm, to meet the needs of high-precision Spreader.

QAt present, which model of film Film thickness control accuracy is higher? Adhesive (including some coatings) products, viscosity 500~ 3000

A

Sample viscosity is relatively high, you can use drawdown blade Vacuum chuck Automatic Film Applicator, our seventh generation, drawdown blade straightness and equipment table flatness are tested with imported precision instruments to ensure the uniformity and accuracy of the film, differentiator using Qingliang brand, precise control. And can also be equipped with imported high accuracy bar film.

QSubstrate: Glass, PET film, cardboard, etc., coated with 100 micron relatively high viscosity samples, which experimental coater can be used?

A

PET film should be fixed with vacuum adsorption, and it is recommended to use doctor blade + vacuum adsorption Film Applicator.

QWhat is the function of vacuum adsorption?

A

The vacuum adsorption function is used to fix the substrate to ensure that the substrate does not move during the Spreader process, ensuring the accuracy and conformity of the Spreader.

QWhat are the characteristics of the Spreader table material of the flat coater?

A

The Spreader table is made of hard-treated aluminum alloy with high abrasion resistance and Smoothness, providing a stable working platform.

QWhat is the thickness and accuracy of the doctor blade film?

A

The thickness range of doctor blade film is 0.1~ 10mm, and the doctor blade accuracy is as high as +/- 0.003mm, which can meet the needs of customers with strict requirements on Spreader thickness and accuracy.

QWhat is the fixing method of the substrate of the small coater?

A

The substrate fixing method adopts the method of vacuum adsorption and fixture to ensure the stable fixing of the substrate during the Spreader process, which improves the accuracy and Stability of the Spreader

Standard

TM2200

TM2200