HuiNuo TM2300 drawdown blade heating Vacuum chuck Film Applicator, small precision Coater

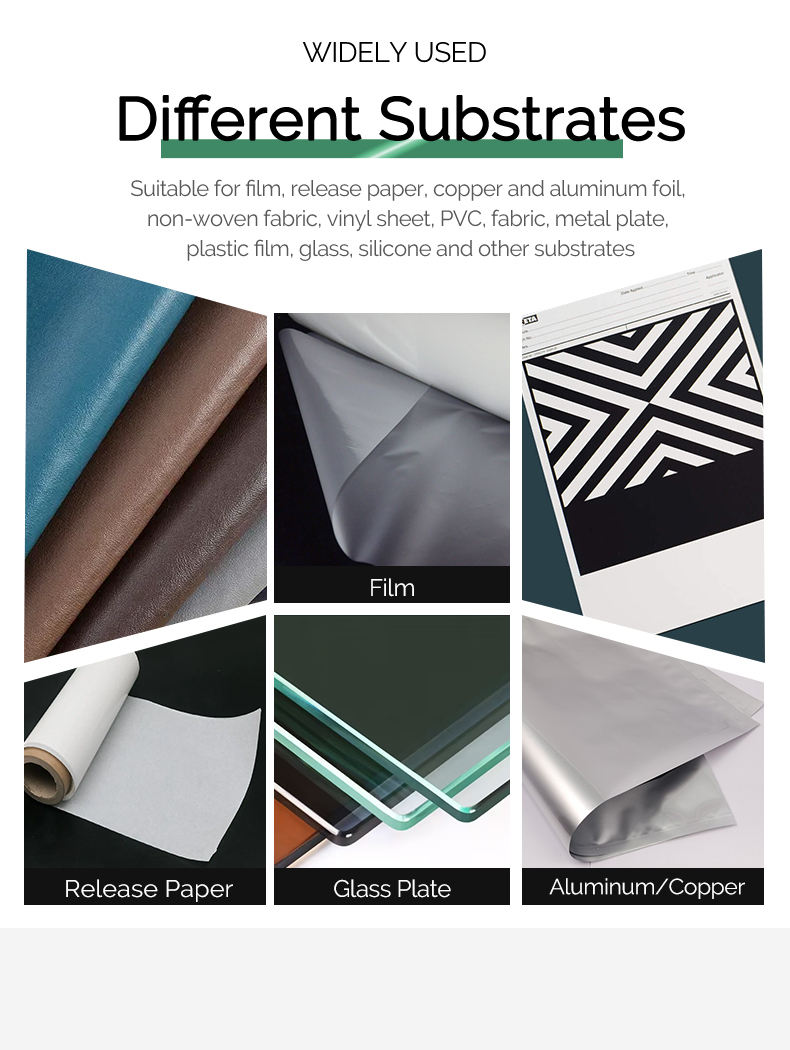

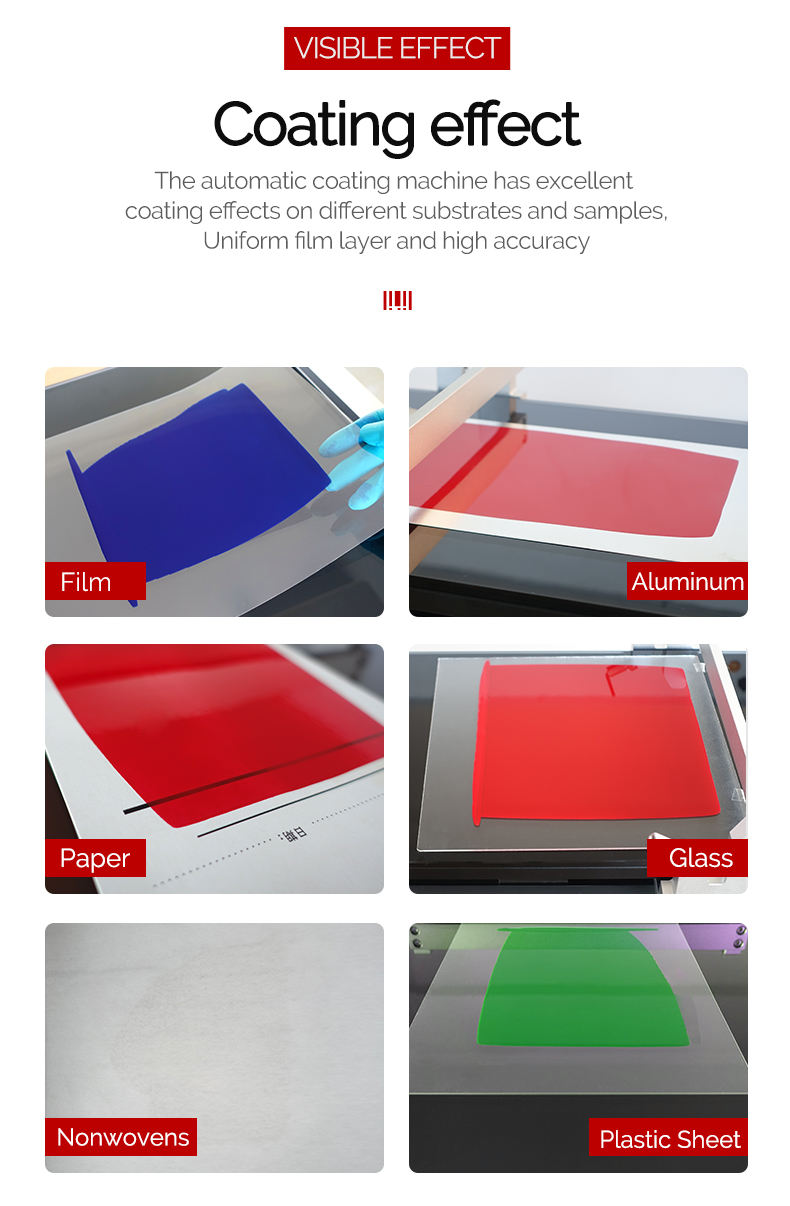

SE BoutiqueDrawdown blade + heating + Vacuum chuck function, clamshell drawdown blade design, Spreader area 400 * 300mm, suitable for soft substrate Spreader proofing, such as film, release paper, aluminum foil copper foil.

$4300.00/set

PromotionLoading...

Coupon

Model:

Similar products

-

CHINA TBJ-X5-DJ7 removable drawdown blade heating vacuum adsorption Film Coater Coating size 500 * 1000mm$ 10722.00SE

CHINA TBJ-X5-DJ7 removable drawdown blade heating vacuum adsorption Film Coater Coating size 500 * 1000mm$ 10722.00SE -

China TBJ-X5-DJ5 Vacuum chuck Drawdown blade Coater$ 4300.00SE

China TBJ-X5-DJ5 Vacuum chuck Drawdown blade Coater$ 4300.00SE -

China TBJ-X5 Vacuum chuck Drawdown blade Lab Film Applicator with Heating Coating Machine$ 3830.00SE

China TBJ-X5 Vacuum chuck Drawdown blade Lab Film Applicator with Heating Coating Machine$ 3830.00SE -

China TBJ-X5-DJ1 Vacuum chuck Drawdown blade Lab Film Applicator with UV light curing Coating Machine

China TBJ-X5-DJ1 Vacuum chuck Drawdown blade Lab Film Applicator with UV light curing Coating Machine -

MODERNER AFA-VH Electric Vacuum Automatic Film Applicator

MODERNER AFA-VH Electric Vacuum Automatic Film Applicator

HuiNuo TM2300 Automatic Film ApplicatorSPEC

HuiNuo TM2300 Automatic Film ApplicatorDetails

HuiNuo TM2300 Automatic Film ApplicatorPacking list

- SKU

- NB045737

- Coating Method

- Drawdown blade Spreader

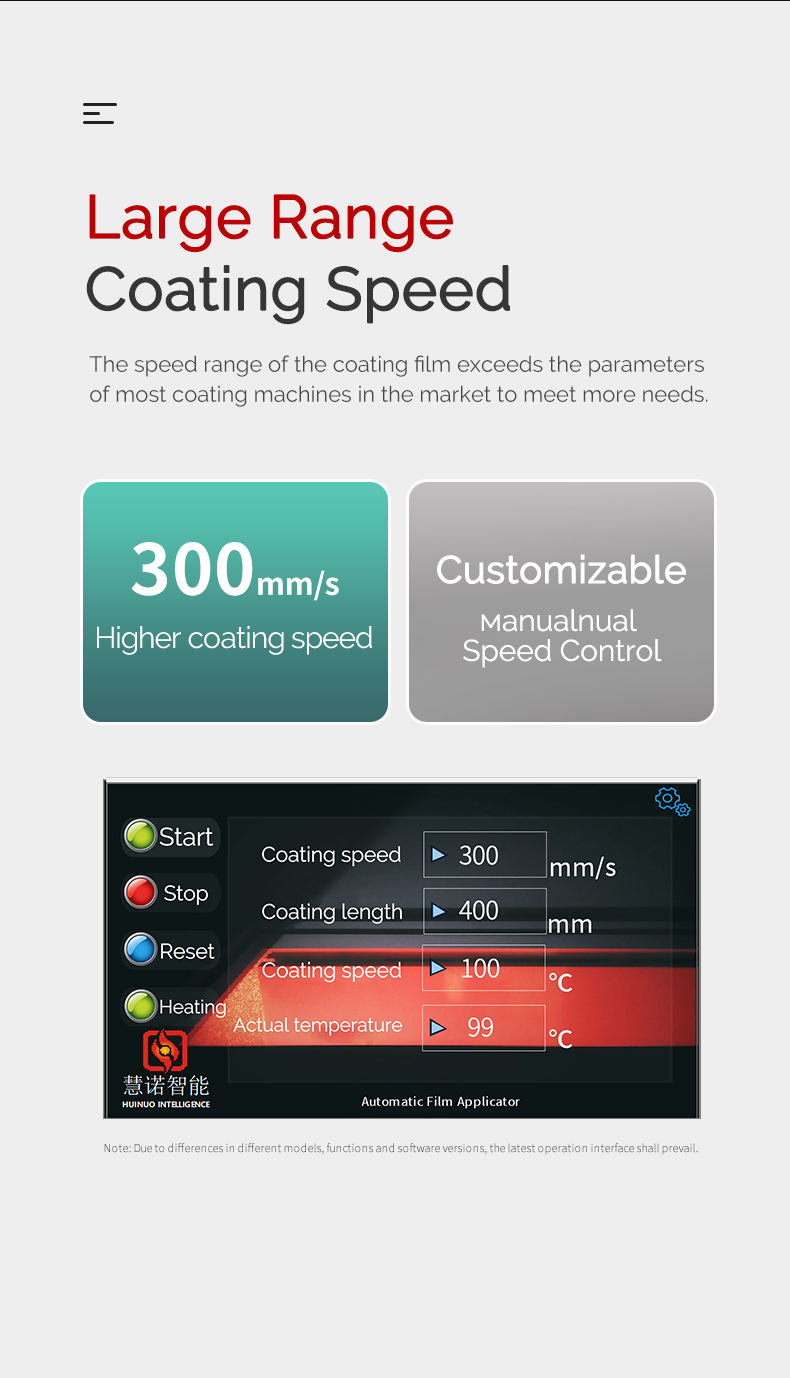

- Coating Speed

- 1~ 300Mm/s stepless speed regulation (can be customized)

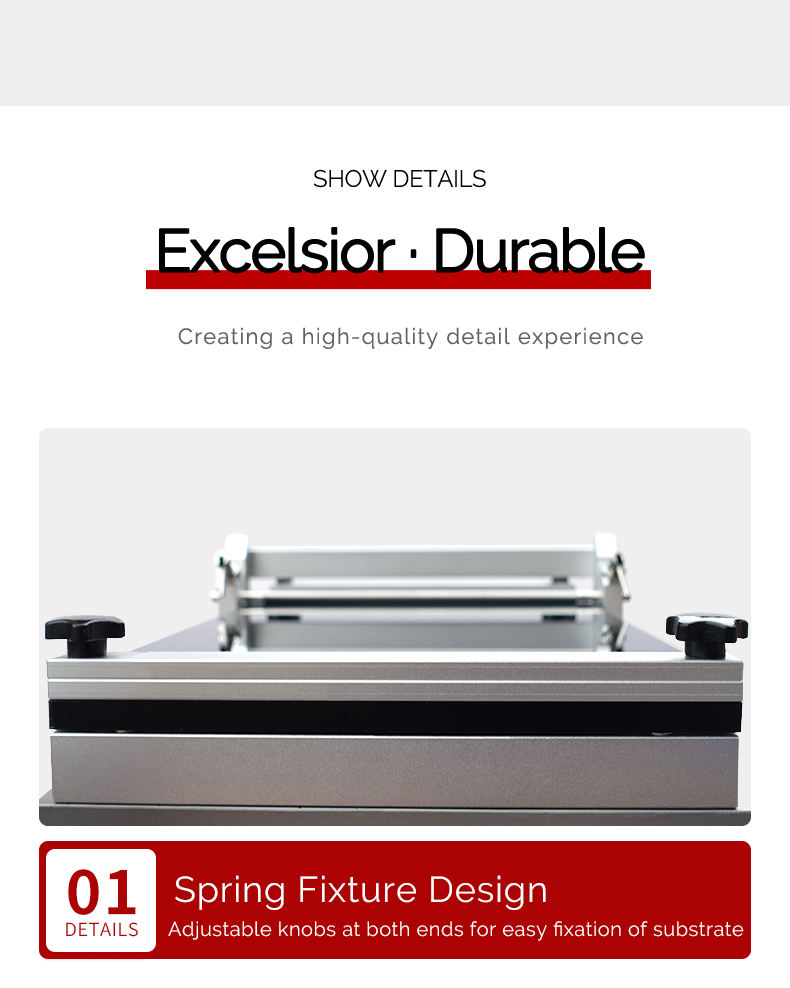

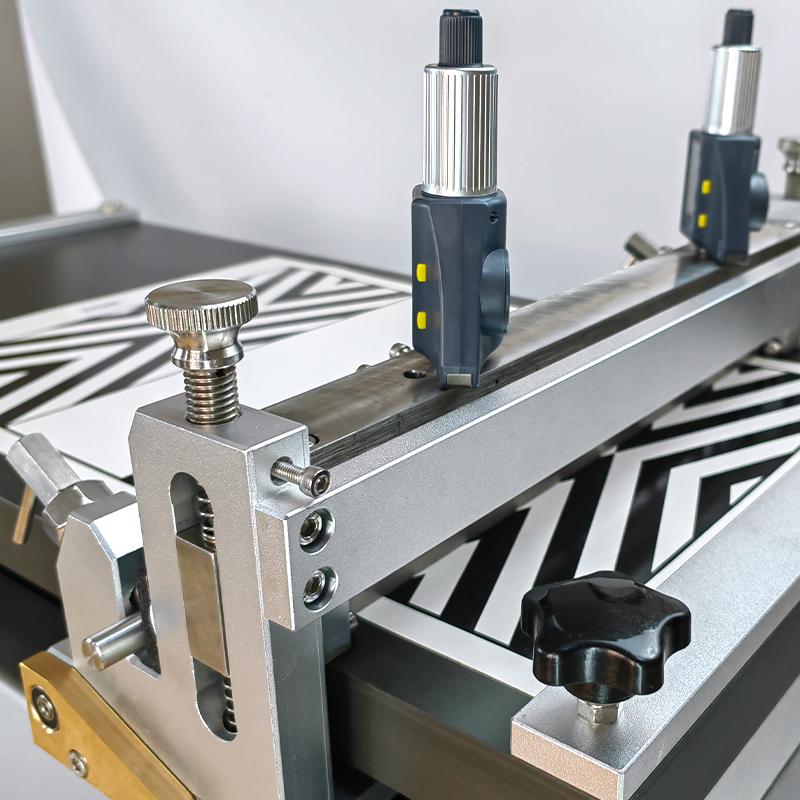

- Substrate clamping method

- Vacuum chuck + fixture

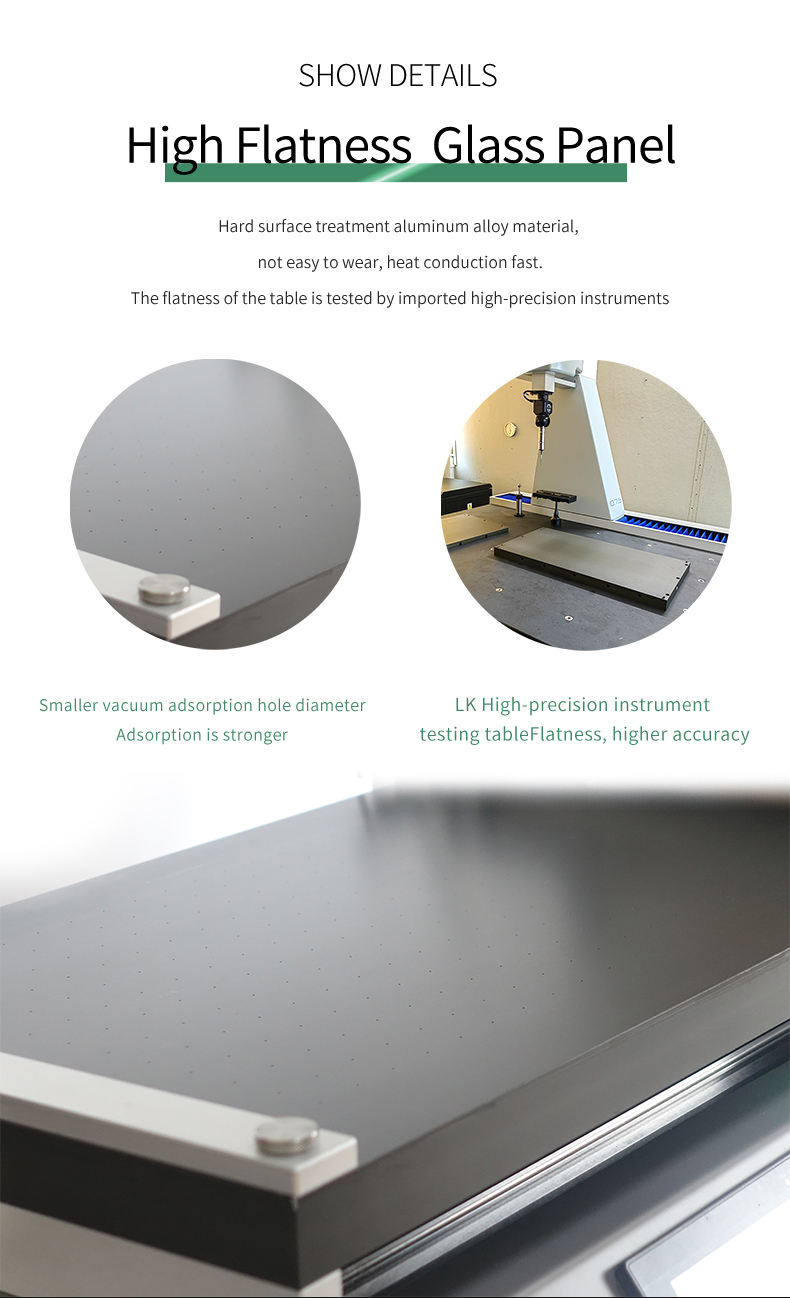

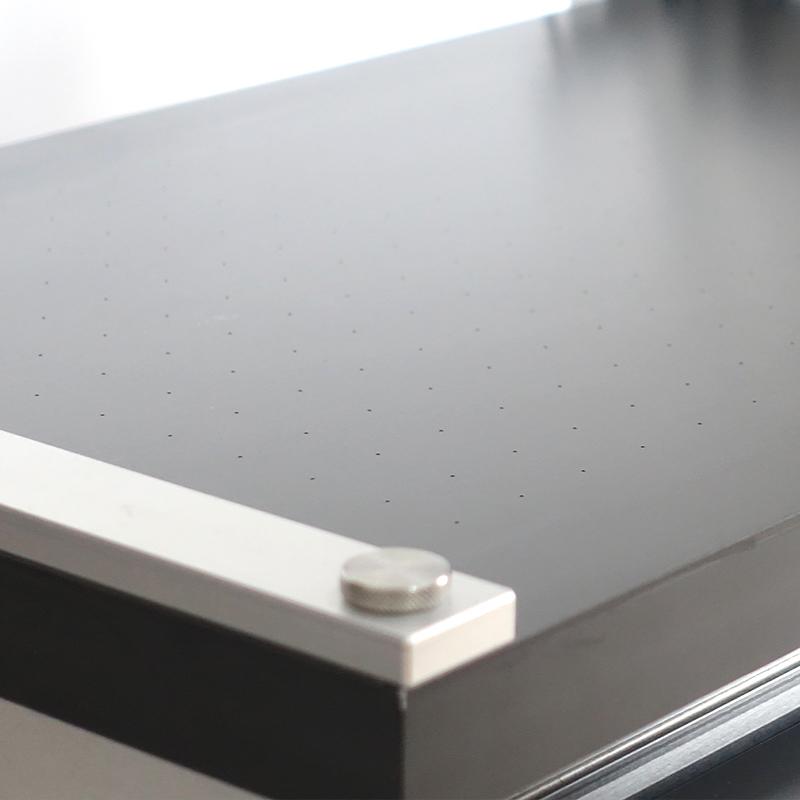

- Coating table material

- Surface hard treatment aluminum alloy

- Coating table size

- 600*300mm

- Effective coating Area

- 400 * 300Mm (can be customized)

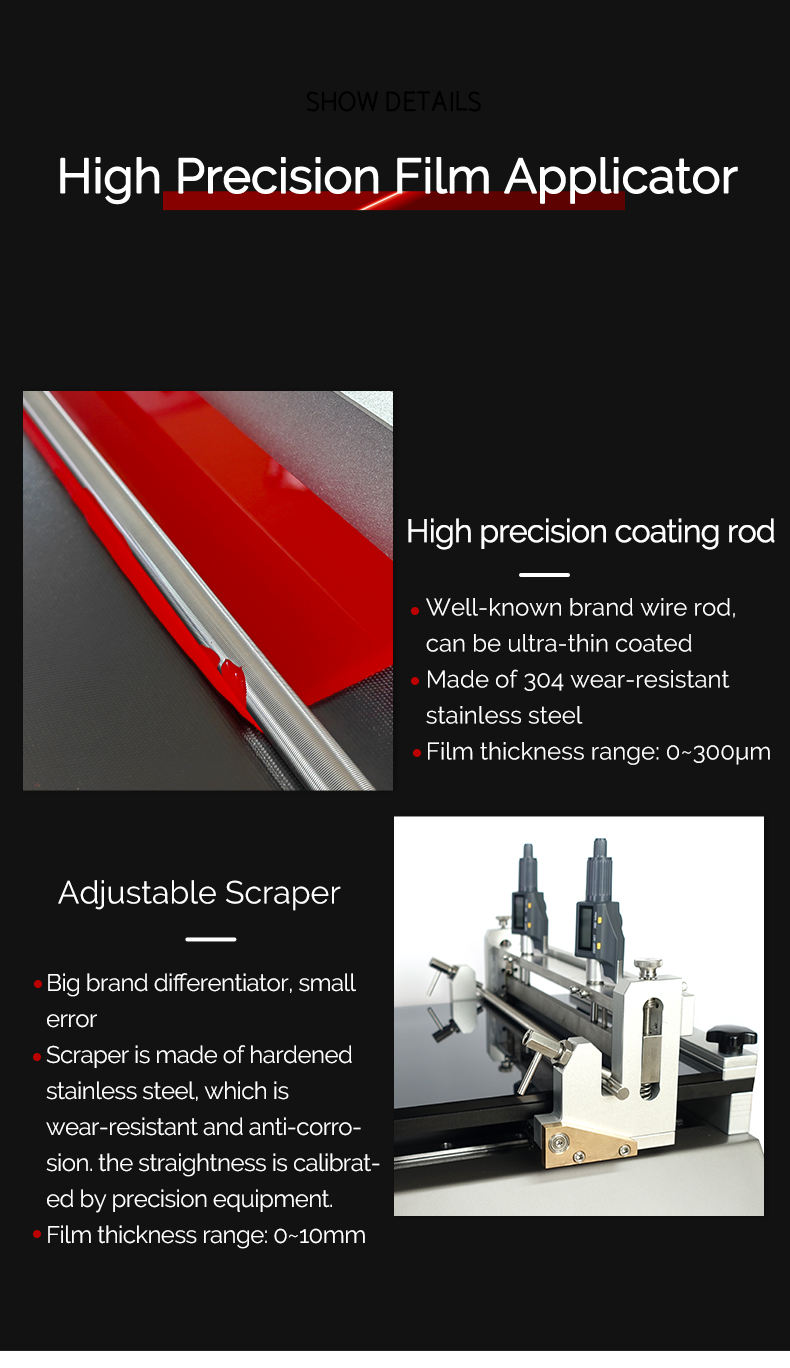

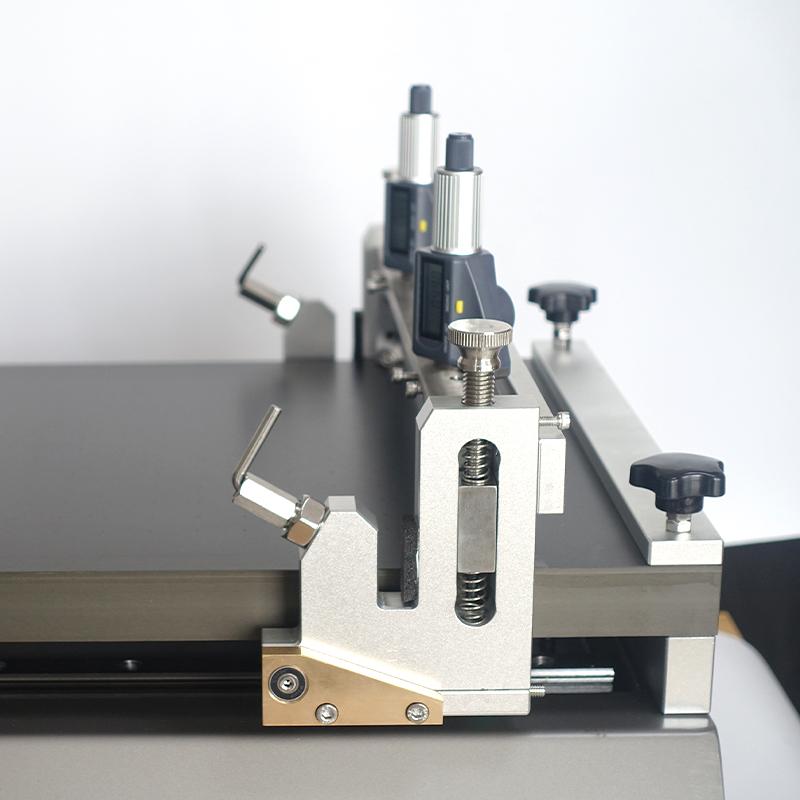

- Drawdown blade Spreader Film thickness range

- 0~10Mm (clamshell design is easy to clean)

- Drawdown blade material

- Die steel

- Drawdown blade Spreader width

- 300mm

- Drawdown blade Spreader Accuracy

- ±0.003mm

- Vacuum chuck size

- 480 * 260Mm (can be customized)

- Vacuum Aperture

- Φ0.8mm

- Vacuum hole pitch

- 20*20mm

- Vacuumpump pumping rate

- 5.4m3/h

- Ultimate Vacuum

- 50KPa

- Vacuumpump power

- 180W

- Vacuumpump Weight

- 7.1kg

- Vacuumpump power

- 180W

- Heating method

- Mica sheet heating (optional graphene heating, faster thermal conductivity)

- Heating temperature range

- RT +~ 180 ℃ (can be customized)

- Temperature Uniformity

- ±1℃

- Display

- Color LCD touch screen

- Host Power Supply

- 100V~220V/50~60HZ

- power

- 1800w

- operating language

- Chinese (can be customized in English)

- Dimensions

- 658*438*400mm

TM2300

Automatic Film Applicator

Drawdown blade + heating + Vacuum chuck function, clamshell drawdown blade design, Spreader area 400 * 300mm, suitable for soft substrate Spreader proofing, such as film, release paper, aluminum foil copper foil.

FAQ

QRelease paper coated with glue, and film, coated with 100 micron Film thickness, which Automatic Film Applicator is suitable?

A

Vacuum chuck heating drawdown blade Automatic Film Applicator.

QWe are doing hot-melt adhesive, need to use PET/Miscellaneous coil pull film, film (excluding substrate) Film thickness needs to be below 25um, which Automatic Film Applicator is suitable?

A

Hot-melt adhesive viscosity is high with drawdown blade scraping, film substrate to choose Vacuum chuck function, recommended drawdown blade heating Vacuum chuck Automatic Film Applicator.

QRecommend a hot-melt adhesive Film Applicator, coated with a transdermal patch, the thickness range is less than 1mm, and the heating function is required.

A

Doctor blade + heating + vacuum adsorption Automatic Film Applicator can.

QWhat is special about the film Coater doctor blade design?

A

Film Coater adopts clamshell type doctor blade design, which makes cleaning more convenient, reduces cleaning time cost and improves work efficiency.

QExcuse me, is the baseplate heated? Do you need a thermal insulation cover?

A

It is baseplate heating, no thermal insulation cover is required.

QWhat is the difference between Doctor Blade Spreader and Wire Spreader?

A

The doctor blade coater adopts the doctor blade Spreader method, which is more suitable for moulding of samples with thicker coatings or higher viscosity than the wire rod Spreader. The wire rod Spreader is more suitable for scenes with strict requirements on the thickness accuracy of the Spreader or samples with lower viscosity.

QIs the Spreader speed for this Film Applicator adjustable?

A

Yes, the Spreader speed can be adjusted, with a range of 5 to 250mm/s, stepless speed regulation, and can be flexibly set according to actual needs.

Standard

TM2300

TM2300