RDS 4 #1/4 "coating bar film thickness 9.1μm rod diameter 6.35mm

SE-

RDS 4 #3/8 "Mayer Rods WFT 9.1μm inks Color tinctorial strength inspection$ 162.00SE

RDS 4 #3/8 "Mayer Rods WFT 9.1μm inks Color tinctorial strength inspection$ 162.00SE -

RDS 4 #1/2 "Formed Mayer Rods 9.1μm wide-wound drawdown Bar$ 181.00SE

RDS 4 #1/2 "Formed Mayer Rods 9.1μm wide-wound drawdown Bar$ 181.00SE -

US RDS 4 #1/4 "wire-wound Applicator rod film thickness 9.1 μm Wire diameter 0.10mm$ 156.00SE

US RDS 4 #1/4 "wire-wound Applicator rod film thickness 9.1 μm Wire diameter 0.10mm$ 156.00SE -

RDS 4 #3/8 "4 Molded inks Scraper 9.1 μm Applicator rod$ 162.00SE

RDS 4 #3/8 "4 Molded inks Scraper 9.1 μm Applicator rod$ 162.00SE -

Japan OSP-09/400 Mayer Rods WFT 9μm length 400mm$ 173.00SE

Japan OSP-09/400 Mayer Rods WFT 9μm length 400mm$ 173.00SE

RDS 4# 1/4“ Applicator rod 1/4 "SPEC

RDS 4# 1/4“ Applicator rod 1/4 "Details

RDS 4# 1/4“ Applicator rod 1/4 "Packing list

- SKU

- NB004586

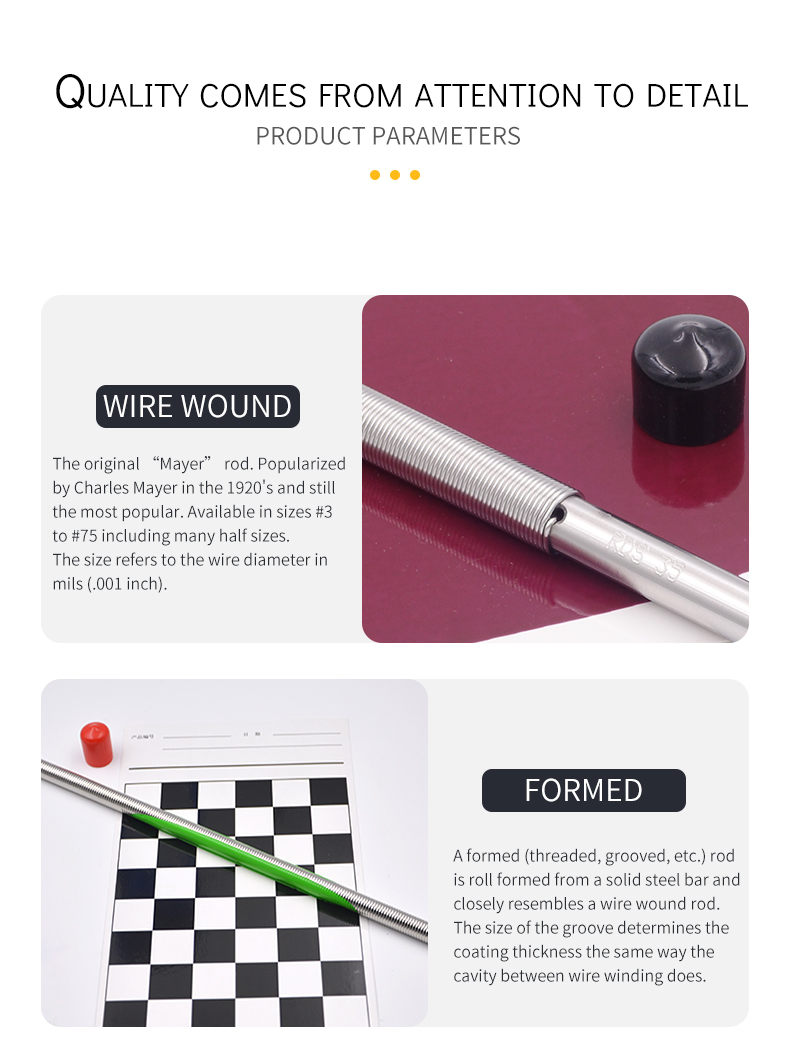

- Production process

- formed

- WFT

- 9.1μm

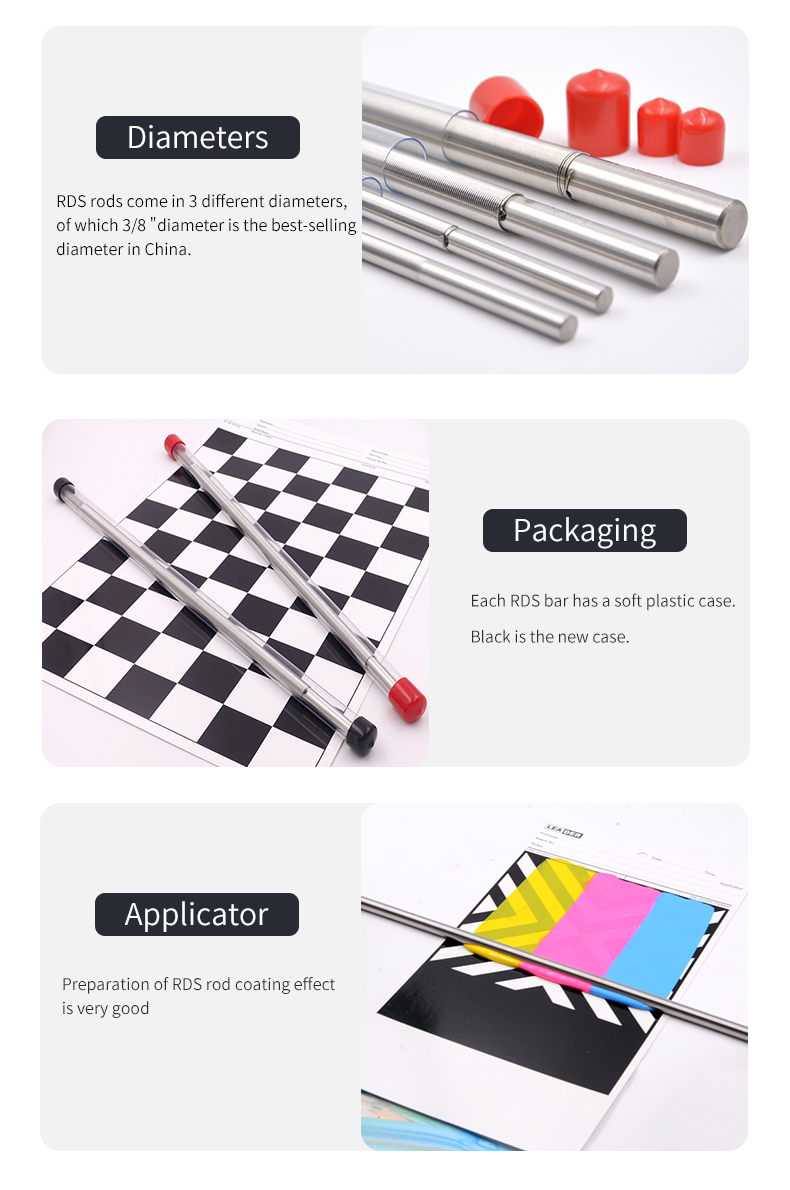

- diameter

- 6.35mm

- Total length

- 400mm

- application width

- 300mm

- Grip Width

- 50+50mm

- material

- stainless steel

Product description

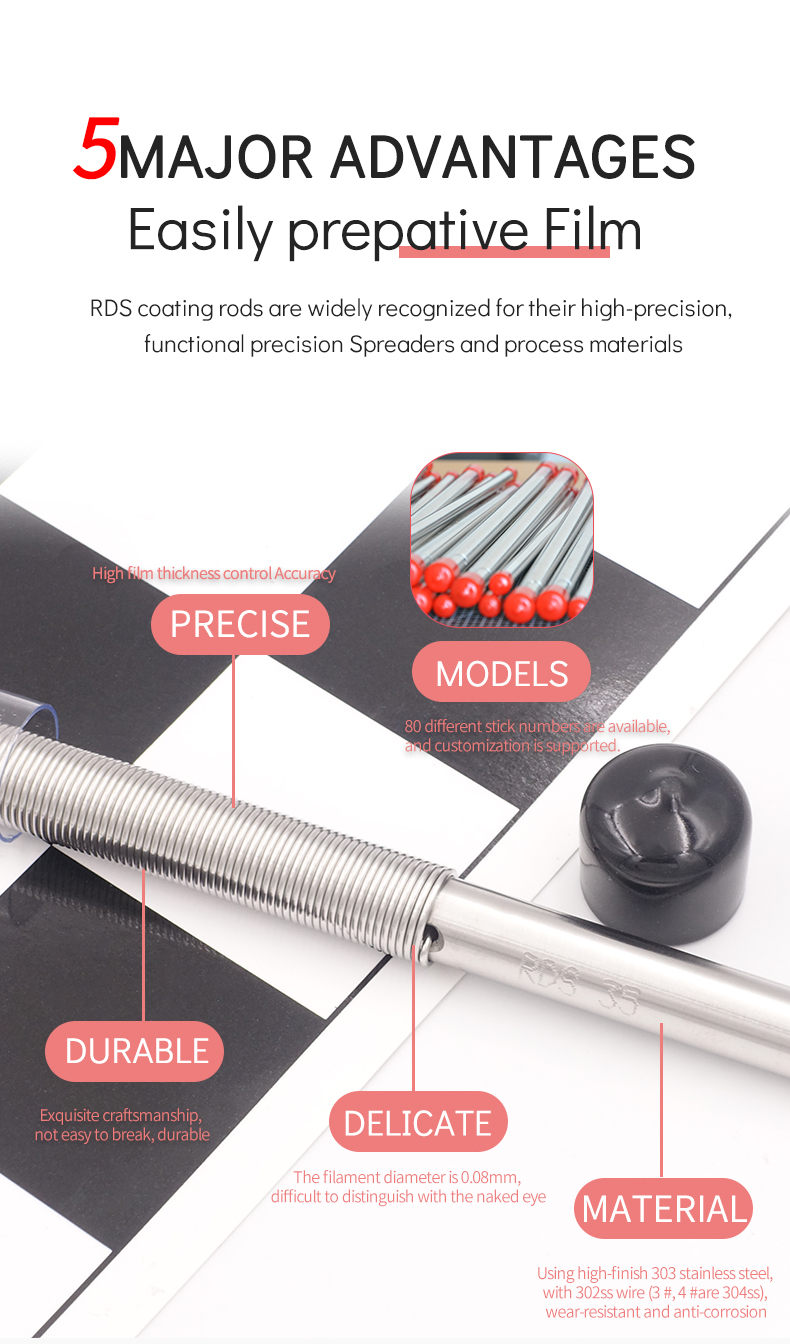

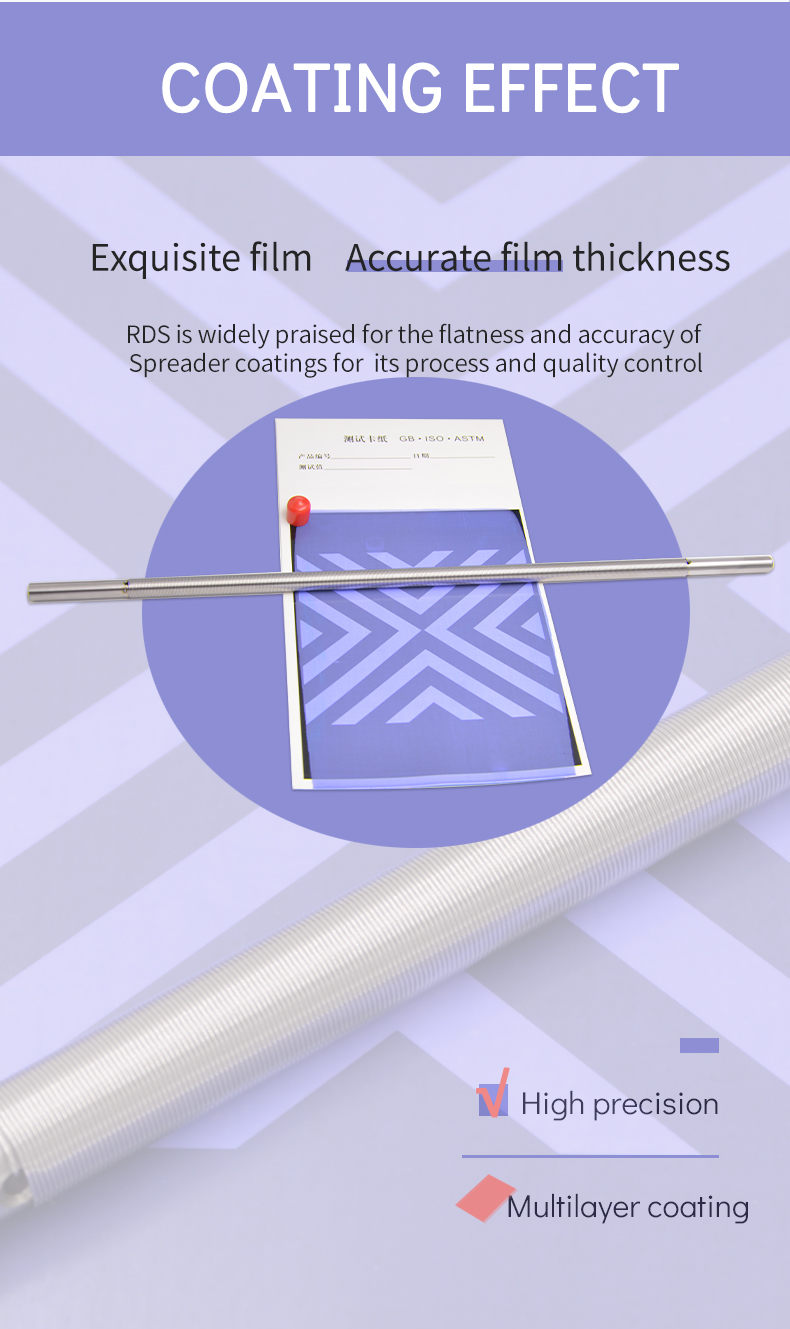

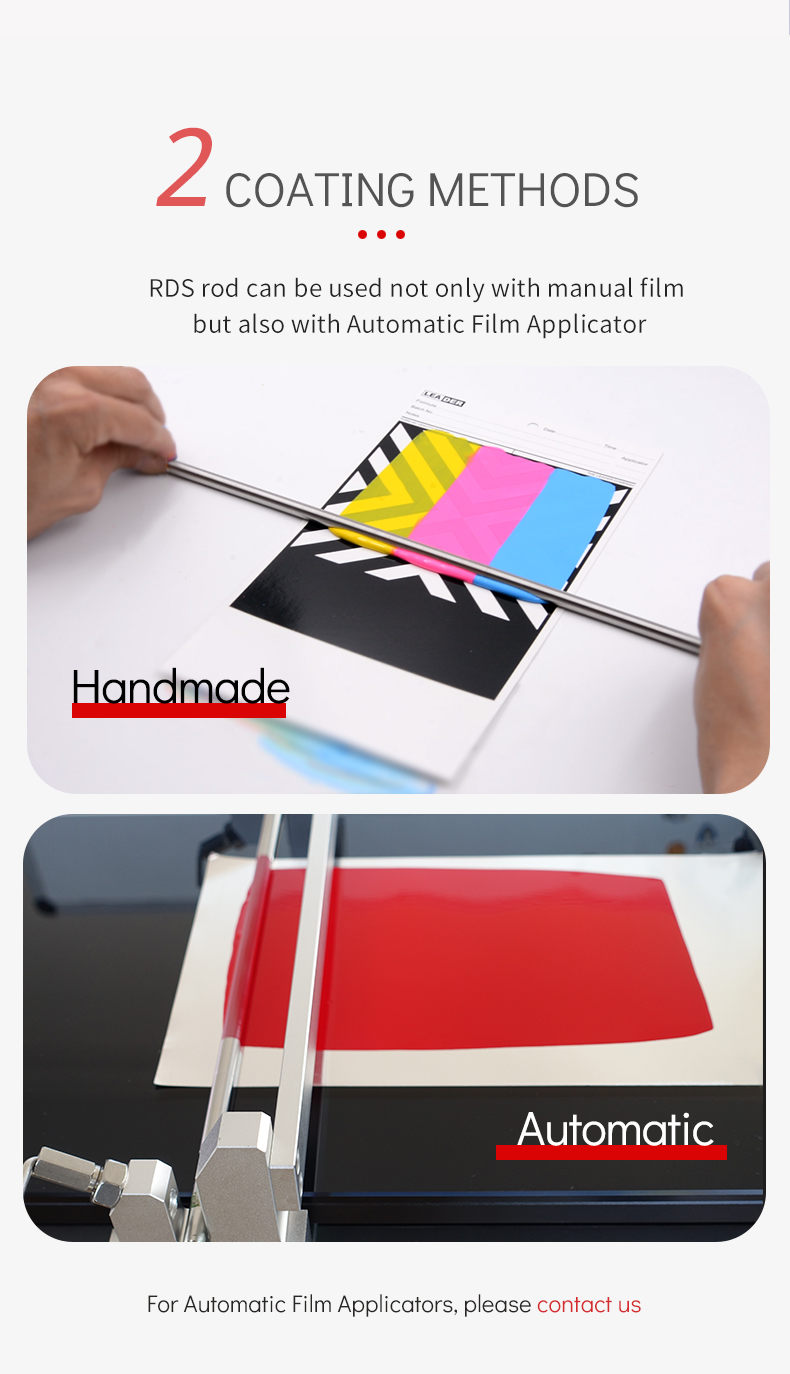

Due to its high precision and ultra-thin coating machine technology, RDS No. 4 wire rod coater is very popular among users in many industries. Up to now, RDS4 coating rods are widely used in coatings, ink industries, building materials, chemical engineering, colleges and universities, scientific research institutions, plastics and even machinery manufacturing and biomedical industries. No. 4 wire Bar Coater can prepare 9.1 micron wet film, which is the mainstream model chosen by most domestic (CN) customers. If you don’t know how to choose a suitable wire Bar Coater, you can use the wet film thickness calculator developed by NBCHAO to calculate. In addition, if you only have the target value of dry film thickness, it is recommended that you use the solid content, dry film and wet film The conversion formula is used to calculate and select the appropriate wet film.

- 1GB/T 1727-2021《General methods for preparation of coating films》

- 2GB/T 7044-2022《Colour carbon black》

- 3HG/T 5370-2018《Waterborne coatings for bicycles》

- 4HG/T 3951-2007《Water based colorants for architectural coatings》

- 5GB/T 13217.1-2020《Test method for colour and tinctorial strength of ink》

- 6HG/T 3948-2007《Hot Melt Adhesives for Sanitary napkin & Panty liner》

- 7GB/T 13217.7-2009《Test method for adhesion to substrate of liquid ink with tape》

- 8GB/T 13217.1-2009《Test method for colour of liquid ink》

- 9GB/T 26461-2011《Gravure ink for paper》

- 10ASTM D823-2018《Paints, varnishes and related products of uniform thickness on the test board》

4# 1/4“

4# 1/4“