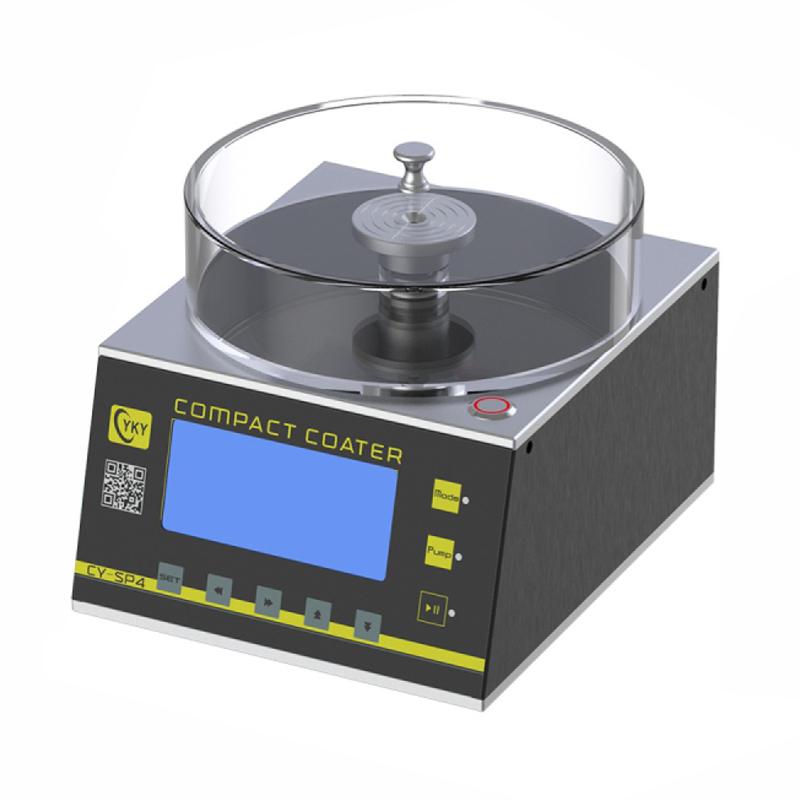

Chengyue CY-SPC4-PMMA Spinning Coater Spin Coater 10000 rpm programmable homogenizer

SEChengYue CY-SPC4-PMMA Spin CoaterSPEC

ChengYue CY-SPC4-PMMA Spin CoaterDetails

ChengYue CY-SPC4-PMMA Spin CoaterPacking list

- SKU

- NB045914

- Power Supply

- AC220V,50Hz

- Speed range

- 0~10000rpm

- Acceleration range

- 100~5000rpm/s

- RPM resolution

- 1rpm

- single step time

- 3000s

- Suitable substrate

- Diameter ≤ 4 inches (100mm)

- Cavity material

- Transparent acrylic

- Human Machine Interface

- button + LCD screen

- Epoxy method

- Manual glue drop, optional precision syringe pump

- Linear dispersion

- Linear dispersion 5 segments each, a total of 5 Linear dispersions can be stored

- Extraction port

- φ 6mm quick screw interface

- Machine size

- 210*250*180mm

- Machine Weight

- 8kg

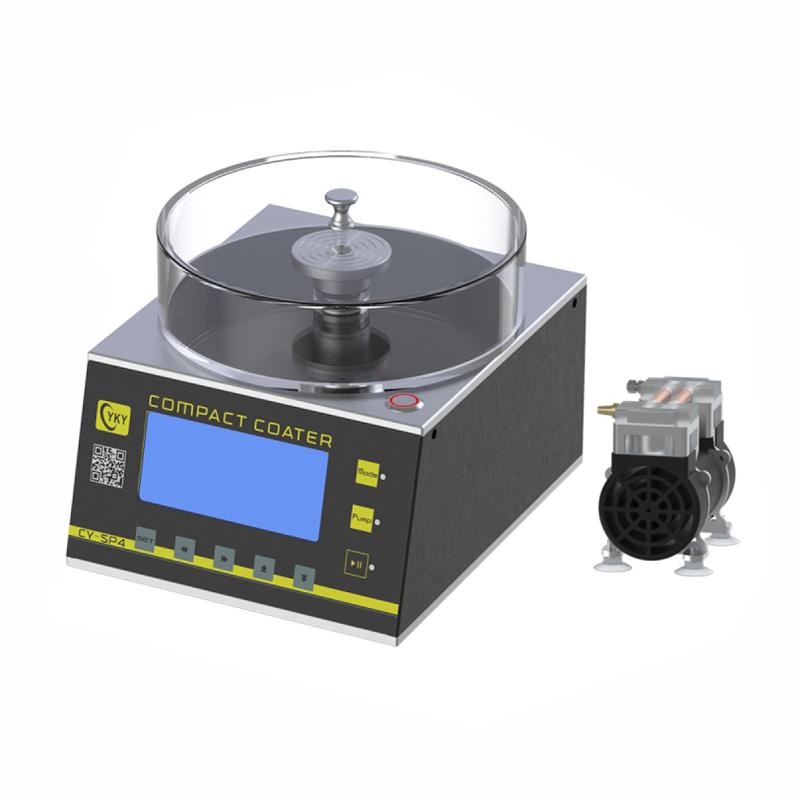

- Vacuumpump

- Dry mechanical pump

- pumping rate

- 50L/min

- Vacuumpump Power Supply

- AC220V 50/60Hz

Product Introduction

CY-SPC4-PMMA homogenizer is designed with a miniaturized design, an aluminum alloy structure, an acrylic cavity, and a beautiful and sturdy appearance. The instrument adopts advanced precision motors, and the maximum speed can reach 8000 rpm; The control relies on buttons and high-brightness LCD screen, and in addition to direct homogenization, it can also pre-store the homogenization curve for programmable homogenization. This instrument effectively guarantees the performance and function of the instrument under the premise of greatly reducing the volume, and is very suitable for laboratory purchase.

Scope of application

The homogenizer can coat liquid or colloidal materials on silicon wafers, crystals, quartz, ceramics and other substrates to form thin films, which are mainly used in photoresist spin coating, biological culture media production, sol-gel method to make polymer films and other fields.

- 1Spin coatings spin coaters: principles, applications, functions and maintenance

- 2Spin Coater selection and classification: a one-stop guide

- 3Application of Spin Coater in preparation of Bi1.5MgNb1.5O7 film

- 4Application of SWIRL/spin Film Applicator in the preparation of metal halide perovskite composite films

CY-SPC4-PMMA

CY-SPC4-PMMA