TQC SP1664 cross-cut Tester Coating, automotive, platings, laboratory, wood and other industries

TQC sheen SP1664 Cross-cut TesterSPEC

TQC sheen SP1664 Cross-cut TesterDetails

TQC sheen SP1664 Cross-cut TesterPacking list

- SKU

- NB004602

- Number of teeth

- 11 teeth

- Tooth spacing

- 1.5mm

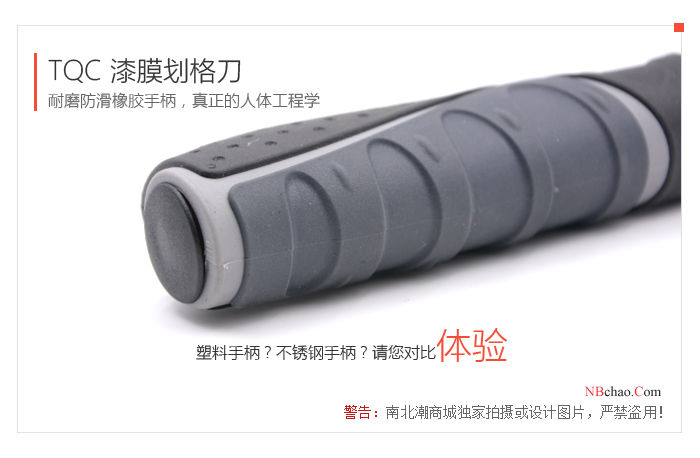

- Instrument material

- Vacuum hardened stainless steel, aluminum, rubber

- Application standard

- ASTM D3359-2009

- Applicable film thickness environment

- 50~125μm

- Appearance size

- 32*173*42mm

- Instrument Weight

- 238g

Introduction

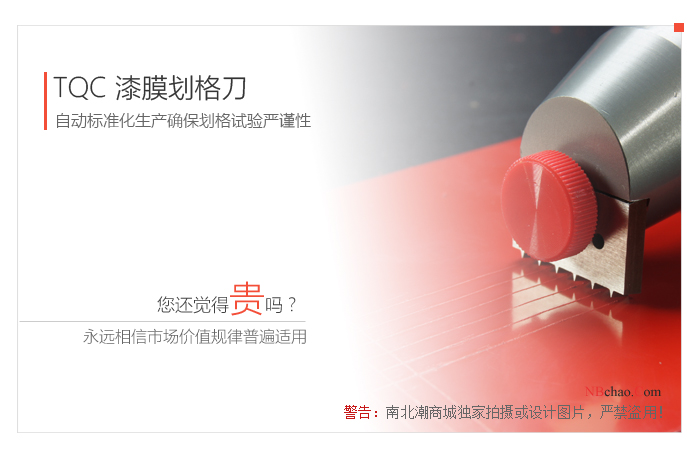

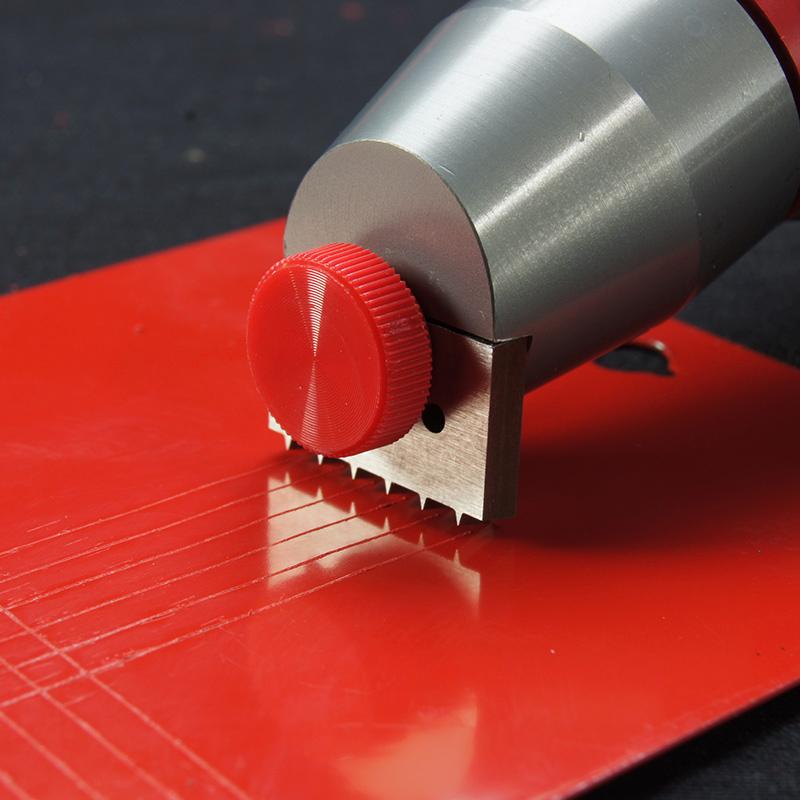

TQC hundred-grid knife (also known as cross-hatch adhesion Tester), available in five models: SP1660, SP1661, SP1662, SP1663, and SP1664, is a method for measuring the adhesion of dry coatings on the surface by making a series of coating incisions. kind of tool. Draw two series of parallel lines, perpendicular to each other, to obtain 25 or 100 squares of similar shapes and sizes. In the scratched area, use a hard-bristle brush to scrub or put tape on it and then tear it off. Observe the treated coating condition and make a judgment based on the standards.

This TQC hundred-grid knife only has one hundred-grid knife. The outer packaging box is a white transparent plastic shell, not a set.

Features

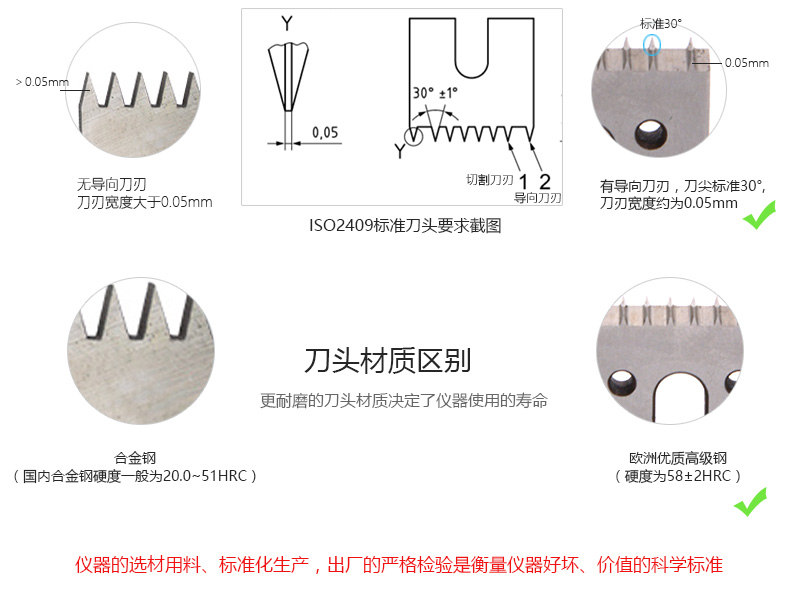

â¢Automatically adjusts the blade holder to ensure consistent pressure exerted by the cutter on the coating

â¢Ergonomic handle

â¢The cutter is easy to replace, no additional tools required

â¢The cutter size range is wide, widely applicable to different coating thicknesses and substrates, and can be selected according to different standards.

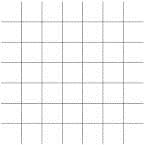

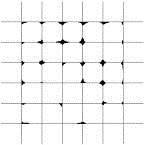

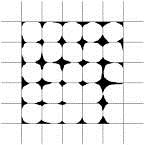

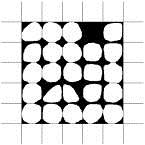

Schematic diagram of the correct use of TQC hundred-grid knife

Standards compliant

ISO/DIN 2409, ASTM D3359

Application

Coatings, automobiles, coatings, laboratories, inks, ships, steel protection, wood and other industries.

Safety Precautions

The blade is sharp, please pay attention to safety when using it;

Please use the box to store the knife.

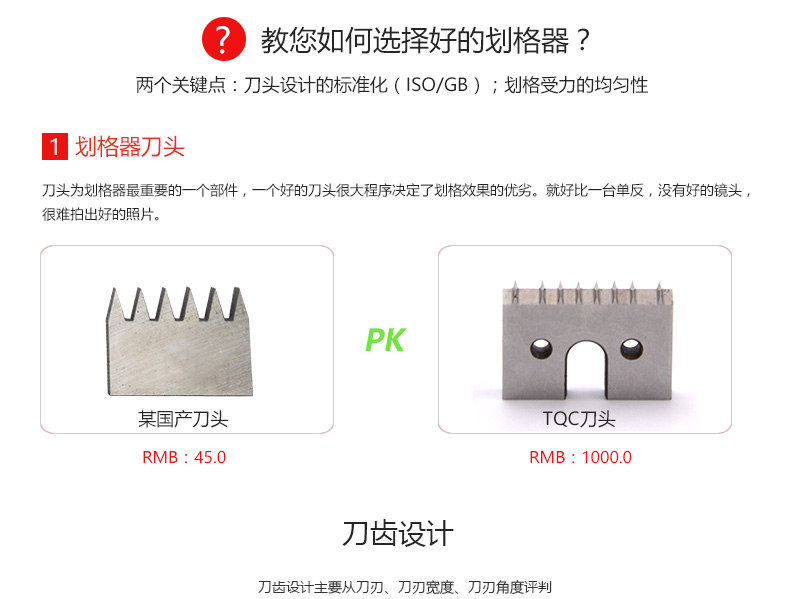

Product details

Optional for Baige Knife

SP3007 1 roll of tape with adhesive force 4.3N/cm

SP3010 3 rolls of tape with adhesive strength 4.3N/cm

SP3020 1 roll of tape with adhesive strength 7.6 N/cm

SP1710 Nylon brush for crosshatch adhesion testing

SP9700 2.5x illuminated magnifying glass

TQC cutter head that meets DIN-ISO standards (applicable to CC2000, CC3000)

SP1702 tooth spacing 1 mm

SP1703 tooth spacing 2 mm

SP1704 tooth spacing 3 mm

TQC cutter head that complies with ASTM standards (applicable to CC2000, CC3000)

SP1705 tooth spacing 1 mm

SP1706 tooth spacing 1.5 mm

Use of 100-square knife

ISO 2409:

1mm intervals, suitable for solid substrates with coating thickness less than 60 microns

2mm intervals, suitable for soft substrates with coating thickness less than 60 microns

2mm intervals, suitable for all substrates with coating thickness between 61 and 120 microns

3mm intervals, suitable for all substrates with coating thickness between 121-250 microns

ASTM D3359:

1mm intervals, suitable for coating thickness less than 50 microns

1.5mm intervals, suitable for coating thickness between 50-125 microns

Cross-hatch method experimental evaluation

| grade | describe | Surface peeling in the cross-cutting area (taking 6 teeth as an example) |

| 0 | The cutting edges are completely smooth and no lines fall off. | |

| 1 | There is a small amount of coating peeling off at the intersection of the cuts, but the cross-cut area should not be significantly affected by more than 5%. | |

| 2 | There is coating peeling off at the intersection of the incisions and/or along the edges of the incisions, and the affected cross-cutting area is significantly greater than 5%, but not significantly greater than 15%. | |

| 3 | The coating is partially or completely peeled off in large fragments along the cutting edge and partially or completely peeled off at different parts of the grid. The affected cross-cut area is significantly greater than 15%, but not significantly greater than 35%. | |

| 4 | Large fragments of the coating peel off along the cutting edge and some squares are partially or completely peeled off. The affected cross-cutting area is significantly greater than 35%, but not significantly greater than 65%. | |

| 5 | The degree of peeling exceeds grade 4. | |

Take you into the Dutch TQC

- 1JJF 2163-2024《Calibration Specification for Paint Film Scribers》

- 2GB/T 9286-2021《Paints and varnishes—Cross-cut test》

- 3HG/T 20720-2020《Construction and acceptance specification of waterborne anti-corrosion coatings for steel structures in industrial buildings》

- 4HG/T 5776-2020《Water-based coatings for surface of rubber sealing products》

- 5HG/T 5187-2017《Automobile axle spring anticorrosive primer》

- 6HG/T 5299-2018《Optical polyethylene terephthalate(PET) transparent hardening film for indium tin oxide(ITO)》

- 7HG/T 3829-2006《Floor coatings》

- 8ASTM D3359-2023《Standard Test Methods for Rating Adhesion by Tape Test》

- 9GB/T 9286-1998《Paints and varnishes 一 Determination of density》

- 10ASTM D6677-2022《Standard Test Method for Evaluating Adhesion by Knife》

SP1664

SP1664