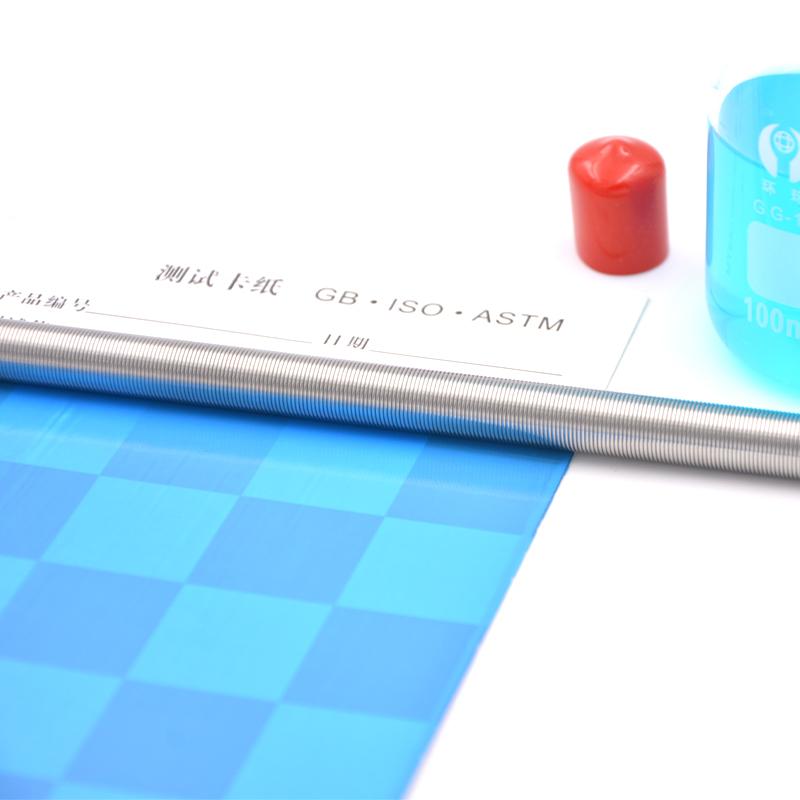

RDS 4 #1/2 "Steel Wire Drawdown Rod film thickness 9.1μm Wire diameter 0.36mm

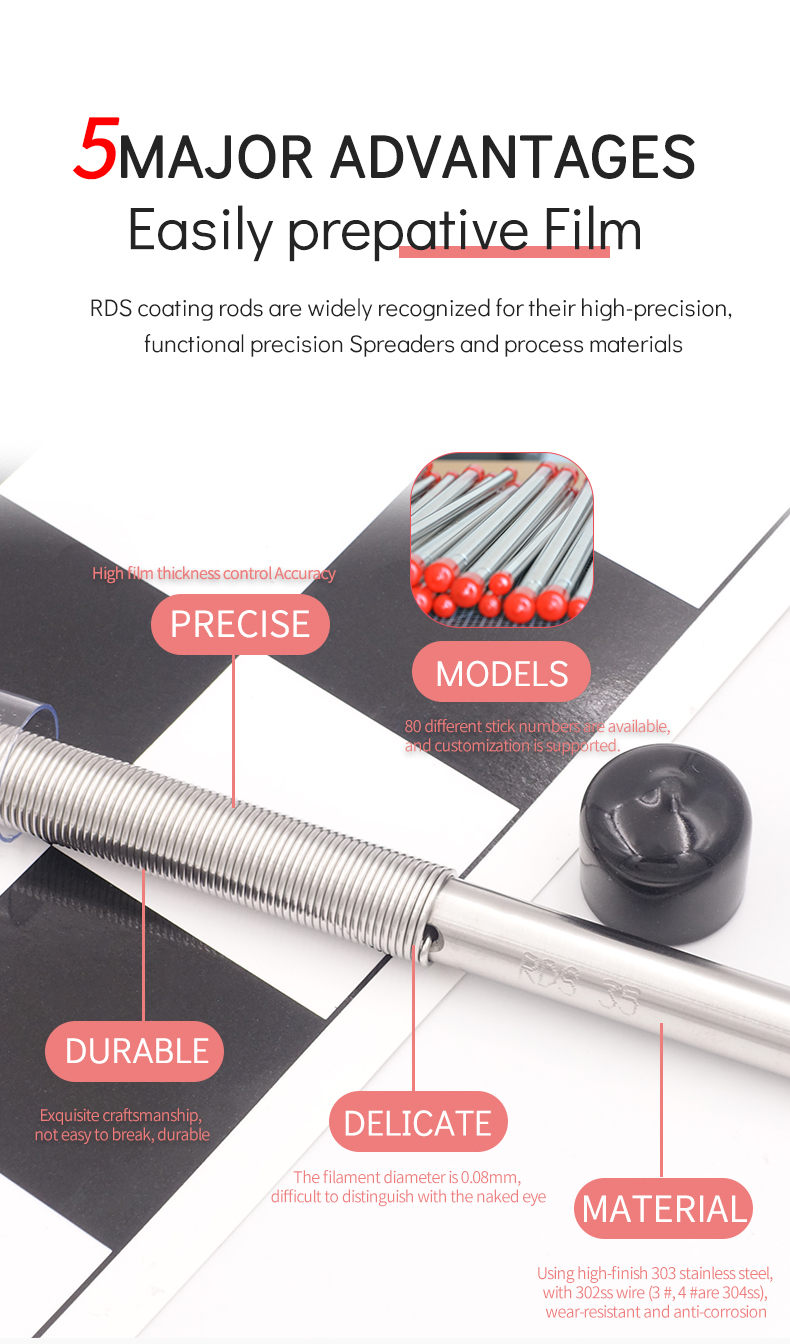

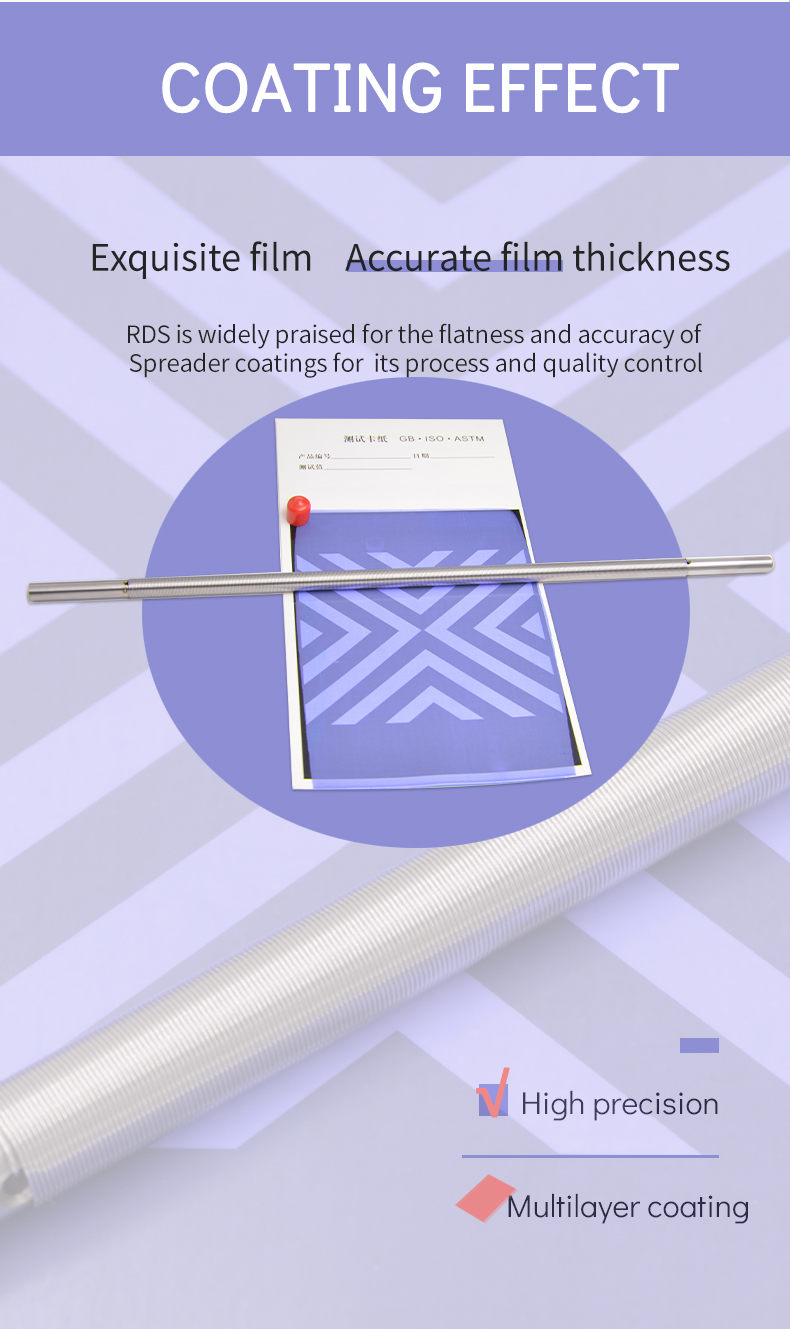

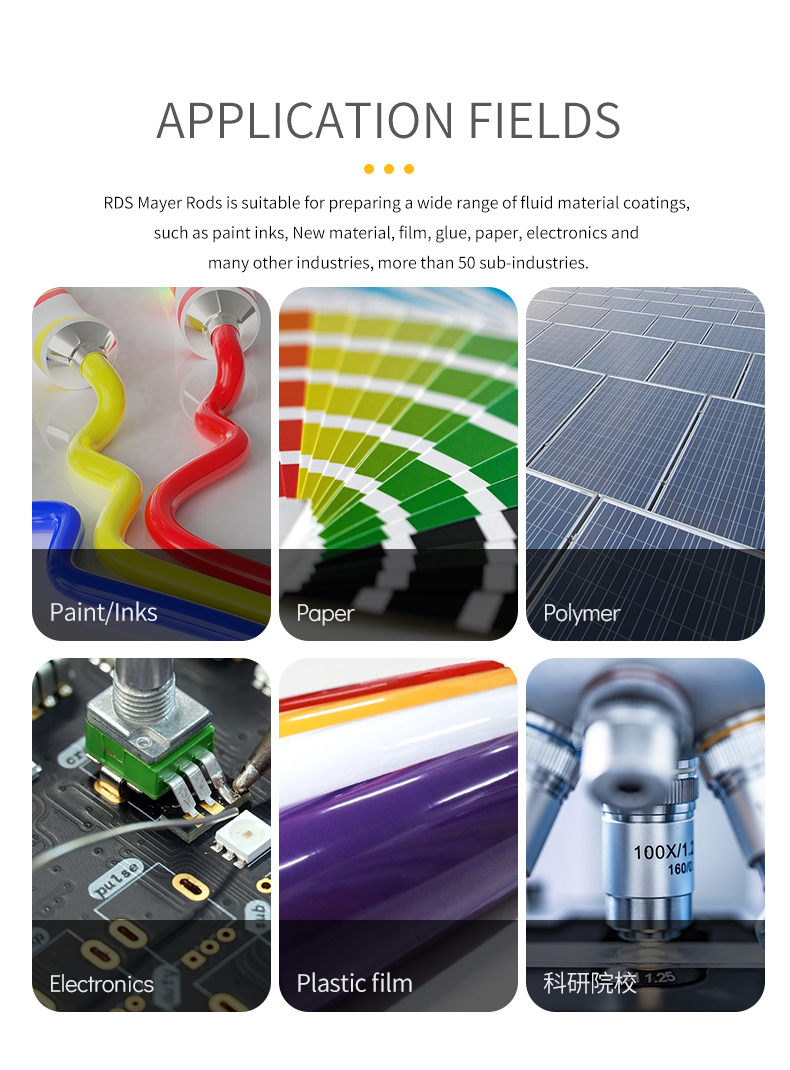

SEWinding process, Wire diameter 0.36mm, rod diameter 12.7mm, the main rod and steel wire are stainless steel, can film 9.1 μm.

$181.00/piece

PromotionLoading...

Coupon

Model:

Similar products

-

RDS 4 #3/8 "Mayer Rods WFT 9.1μm inks Color tinctorial strength inspection$ 162.00SE

RDS 4 #3/8 "Mayer Rods WFT 9.1μm inks Color tinctorial strength inspection$ 162.00SE -

RDS 4 #1/2 "Formed Mayer Rods 9.1μm wide-wound drawdown Bar$ 181.00SE

RDS 4 #1/2 "Formed Mayer Rods 9.1μm wide-wound drawdown Bar$ 181.00SE -

US RDS 4 #1/4 "wire-wound Applicator rod film thickness 9.1 μm Wire diameter 0.10mm$ 156.00SE

US RDS 4 #1/4 "wire-wound Applicator rod film thickness 9.1 μm Wire diameter 0.10mm$ 156.00SE -

RDS 4 #3/8 "4 Molded inks Scraper 9.1 μm Applicator rod$ 162.00SE

RDS 4 #3/8 "4 Molded inks Scraper 9.1 μm Applicator rod$ 162.00SE -

Japan OSP-09/400 Mayer Rods WFT 9μm length 400mm$ 173.00SE

Japan OSP-09/400 Mayer Rods WFT 9μm length 400mm$ 173.00SE

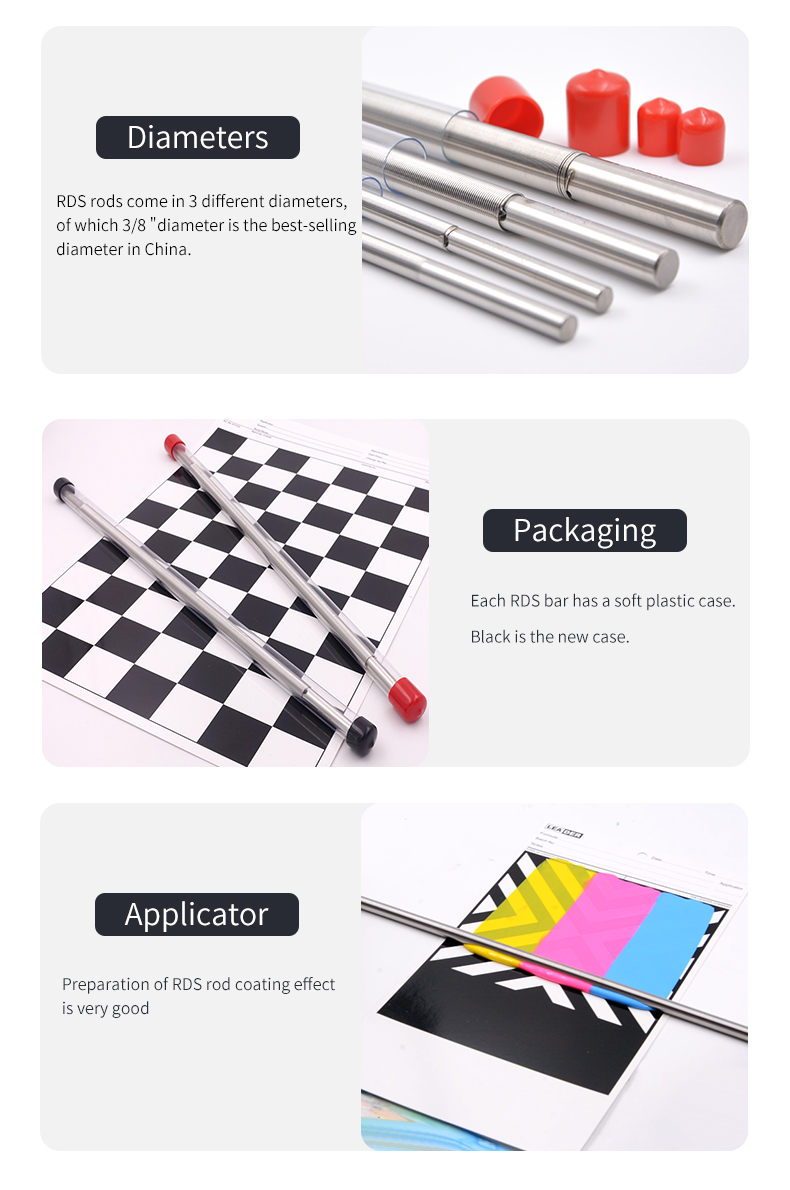

RDS 4# 1/2" Applicator rod 1/2 "SPEC

RDS 4# 1/2" Applicator rod 1/2 "Details

RDS 4# 1/2" Applicator rod 1/2 "Packing list

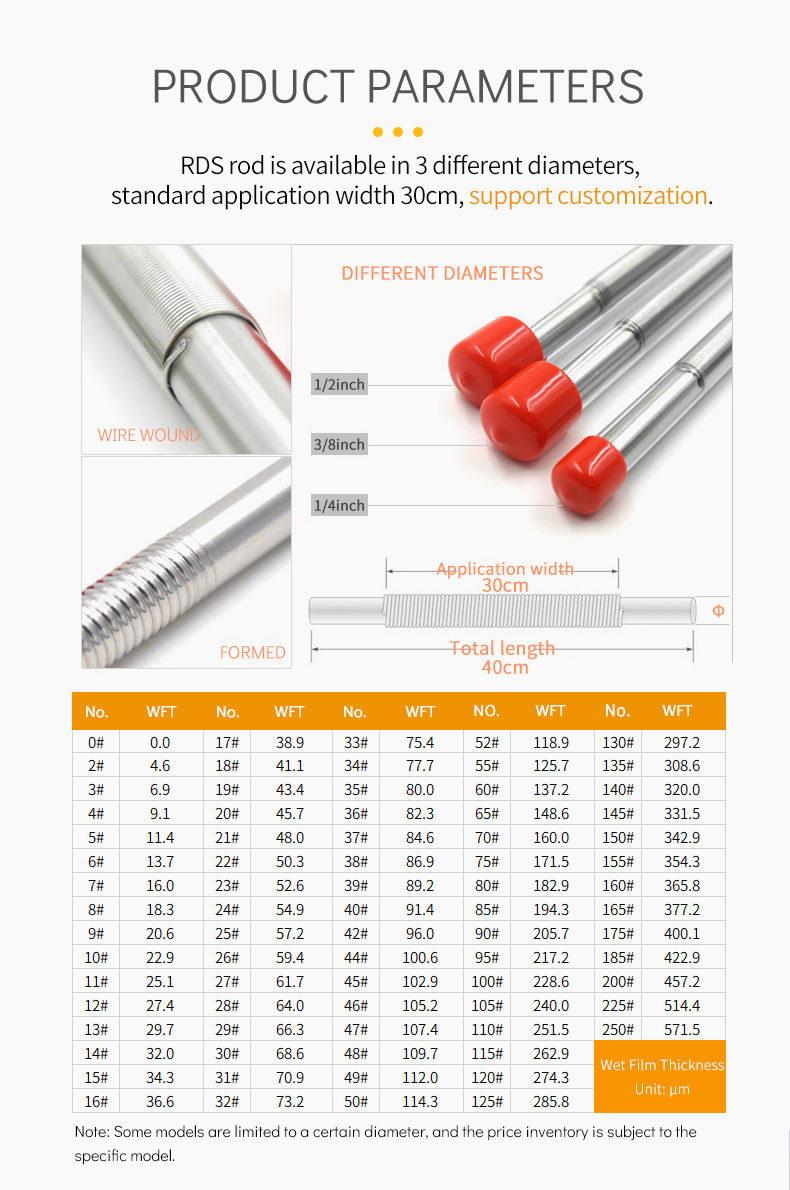

- SKU

- NB004627

- Production process

- Wire-wound

- WFT

- 9.1µm

- diameter

- 12.7mm

- Total length

- 400mm

- Application width

- 300mm

- Grip width

- 50+50mm

- material

- stainless steel

- Wire diameter

- 0.10mm

4# 1/2"

Applicator rod 1/2 "

Winding process, Wire diameter 0.36mm, rod diameter 12.7mm, the main rod and steel wire are stainless steel, can film 9.1 μm.

FAQ

QColor inspection of liquid inks?

A

If you are referring to scraping liquid inks and standard inks samples by Wire-wound drawdown bar to compare Color, use this.

QDo you support customization? Such as wet film thickness and length?

A

Spreader rod length and main rod diameter support customization, but wet film thickness RDS has provided dozens of specifications covering more than 200 microns, and in principle does not accept customization.

QApplicator rod conforms to GB/T13217.7 standard?

A

Applicator rod is suitable for GB/T13217.7, please consult customer service for detailed application definition

QCan this coating rod be prepative of multi-layer ultra-thin film?

A

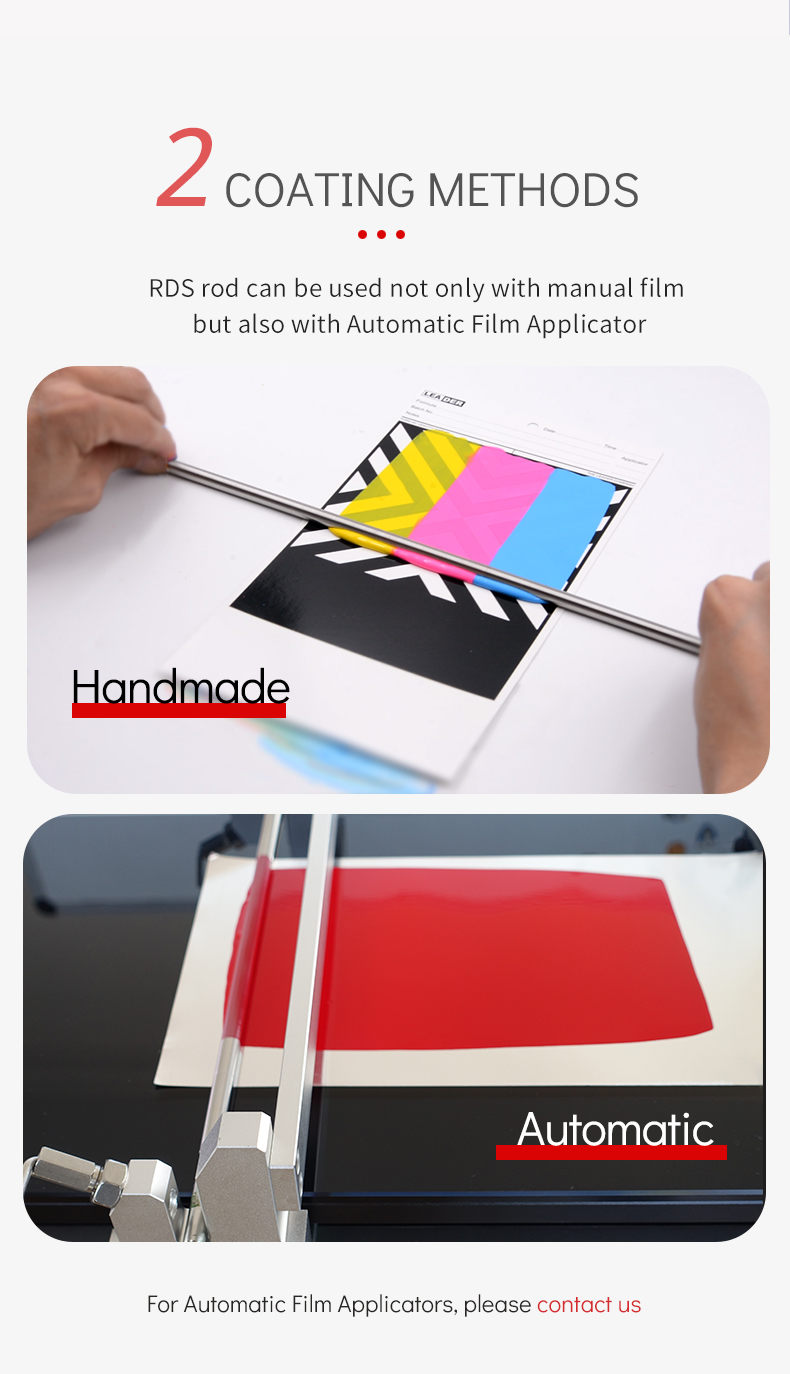

The wire rod can be prepared for 1.5 micron ultra-thin film. Everyone must know it, but another advantage of it is multi-layer film, which is much better than I-shaped film applicator. But multi-layer film tests the flatness of the previous layers of film drying. Generally, the film thickness (such as less than 10 microns/layer) is too thin to control. The wire rod with Film Applicator is a very good solution, eliminating the problem of uneven pressure and speed of hand scraping.

QAdhesive coating, any suggestions?

A

The preparation of Adhesive coating is applicable to the Mayer-Rod principle, and Mayer Rods coating can be used. The thickness of the prepared Adhesive coating can be controlled by itself. In general, Adhesive can be properly diluted (such as ethyl acetate), and then coated on BOPP film or Miscellaneous substrate.

QSpreader for nanowire dispersion solution, is this suitable?

A

Applicator rod is a Spreader for nanowire dispersion solution, and the model selection needs to be selected according to the wet film thickness you need. It is recommended that you refer to NBchao's selection tool.

Knowledge

- 1Application of Mayer Rods in 2D Single Crystal Copper Nanosheet Films

- 2One article introduces RDS Applicator rod type and FAQ

Standard

- 1GB/T 1727-2021《General methods for preparation of coating films》

- 2GB/T 7044-2022《Colour carbon black》

- 3HG/T 5370-2018《Waterborne coatings for bicycles》

- 4HG/T 3951-2007《Water based colorants for architectural coatings》

- 5GB/T 13217.1-2020《Test method for colour and tinctorial strength of ink》

- 6HG/T 3948-2007《Hot Melt Adhesives for Sanitary napkin & Panty liner》

- 7ASTM D4147-2023《Standard Practice for Applying Coil Coatings Using Wire-Wound Drawdown Bars》

- 8GB/T 13217.1-2009《Test method for colour of liquid ink》

- 9GB/T 13217.7-2009《Test method for adhesion to substrate of liquid ink with tape》

- 10GB/T 13217.7-2009《Test method for adhesion to substrate of liquid ink with tape》

4# 1/2"

4# 1/2"