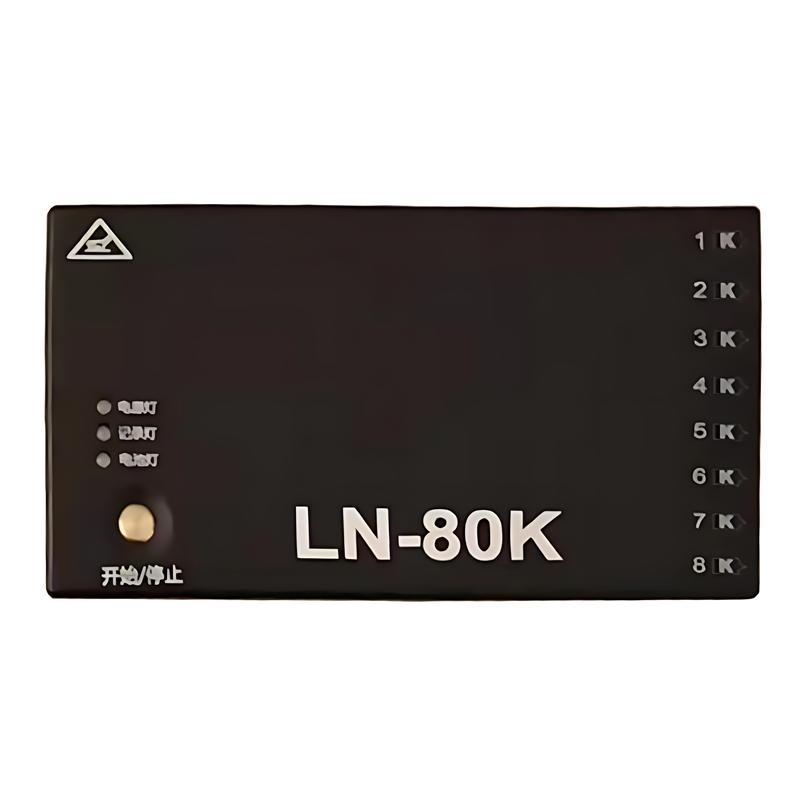

Rennes LN-80K painting Furnace temperature tracker 8 channels 300 ℃ 1 hour

SELeiEn LN-80K Furnace temperature tracker for paintingSPEC

LeiEn LN-80K Furnace temperature tracker for paintingDetails

LeiEn LN-80K Furnace temperature tracker for paintingPacking list

- SKU

- NB046346

- Number of channels

- 8 channel

- Insulation box performance

- 300 ℃ for 60 minutes, 250 ℃ for 70 minutes, 200 ℃ for 80 minutes, 100 ℃ for 180 minutes

- Insulation box range

- 300 ℃; 1-10 hours (customized according to the actual situation of the user)

- memory

- Large memory can record 200,000 data

- Sampling rate

- 1S, 2s, 3s, 4s, 5s, 6s, 10s, 20s, 30s, etc., can be selected by the user

- Computer requirements

- No special requirements, Linear dispersion and various analysis reports can be printed by computer

- Heat insulation box size (length × width × height)

- 268 × 160 × 110Mm customized according to the actual situation of the user

- Insulation box material

- Shell and steel column structure: high temperature resistant 310S stainless steel; Thermal Insulation: nano aerospace environmentally friendly material

- Instrument size (L × W × H)

- 138 × 62 × 20Mm (Miscellaneous data, confirmed according to the actual situation of the user)

- Sensors

- Thermocouple K

- Measurement range

- -200-1370℃

- Fine ℃

- ±0.3℃

Introduction

LN-80K Coating Furnace Temperature Tracker Temperature Range: -50°C~300°C. The good thermal insulation performance enables the test system to operate safely and stably in a high-temperature environment, and carries out multi-directional temperature curve tracking and mapping. The LEIEN furnace temperature Tester and the product pass through the furnace together to track the temperature status of the furnace and the product throughout the process, so as to obtain accurate data in all directions and form a valuable temperature curve analysis report. LEIEN furnace temperature Tester analysis software will carry out various data analysis and calculation, through the data analysis and calculation results, the heating furnace can be accurately optimized and adjusted, so as to achieve the goal of improving product quality, achieving stable and high yield and energy saving.

Scope of application

Painting Baking Furnace Temperature Tracker, Muffle Furnace Temperature Tester, Non-stick Paint Furnace Temperature Tracker, Steel Heat Treatment Furnace Temperature Tracker, Wheel Hub Heat Treatment Furnace Temperature Tracker, Wave Soldering Reflow Soldering Oven Temperature Tester, Automobile Coating Furnace Temperature Tracker, Food Baking Oven Temperature Tracker, Ceramic Firing Furnace Temperature Tracker, Enamel Oven Temperature Tracker, Glass Silk Screen Printing Furnace Temperature Tracker, Glass Baking Flower Annealing Furnace Temperature Tester, Special Customized Furnace Temperature Tester, etc

Features

LEIEN furnace temperature tracker has the characteristics of high cost performance, small size, light weight and superior thermal insulation performance, which is very suitable for small and medium-sized paint and coating enterprises. Such as baking temperature of 300 °C of various powders, paint baking, motor stator dipping and curing process baking, etc. For paint manufacturers: to do a good job of coatings, furnace temperature trackers are indispensable. For users who apply plastic powders and paints for surface treatment: Furnace temperature trackers are indispensable for good product quality.

LEIEN powder coating furnace temperature tracker effectively solves the influence of uneven temperature in powder coating baking, allowing engineers to quickly and efficiently track and control product quality.

LN-80K

LN-80K