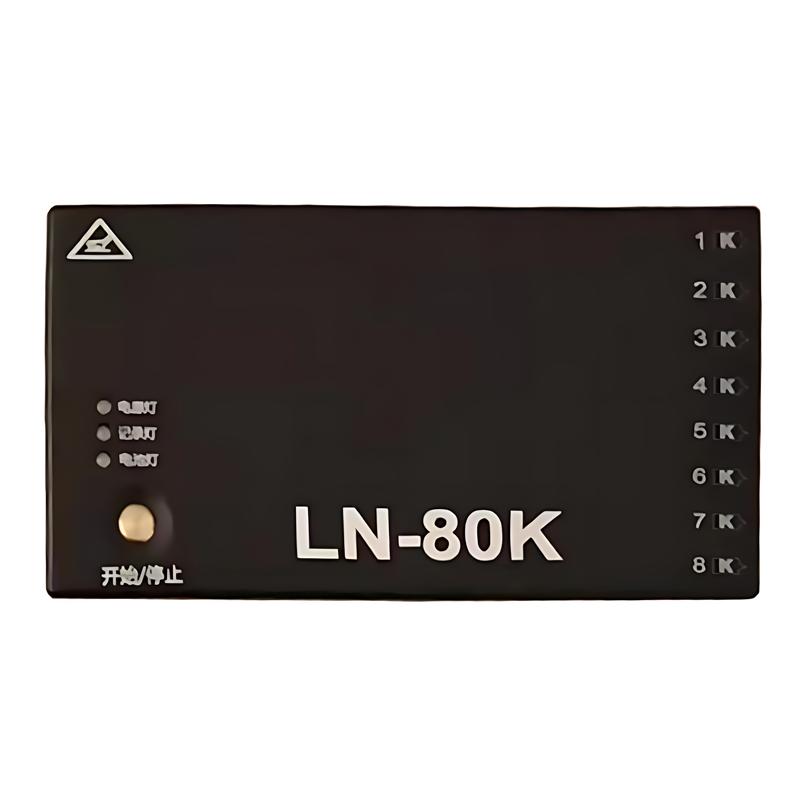

Rennes LN-80K aluminum brazing special Furnace temperature tracker 8 channels 700 ℃ 1 hour

SELeiEn LN-80K Furnace temperature tracker for aluminum brazingSPEC

LeiEn LN-80K Furnace temperature tracker for aluminum brazingDetails

LeiEn LN-80K Furnace temperature tracker for aluminum brazingPacking list

- SKU

- NB046349

- Number of channels

- 8 channel

- Insulation box performance

- 700 ℃ for 90 minutes, 600 ℃ for 100 minutes, 500 ℃ for 120 minutes

- Insulation box range

- 700 ℃; 1-30 hours (customized according to the actual situation of the user)

- memory

- A 1-second recording can be recorded for 4.5 hours, a 2-second recording can be recorded for 9 hours, and so on.

- Sampling rate

- ls, 2s, 3s, 4s, 5s, 6s, 10s, 20s, 30s, etc., can be selected by the user

- Computer requirements

- No special requirements, Linear dispersion and various analysis reports can be printed by computer

- Heat insulation box size (length × width × height)

- 375X238x175mm is customized according to the actual situation of the user.

- Insulation box material

- Shell and steel column structure: high temperature resistant 310S stainless steel; Thermal Insulation: nano aerospace environmentally friendly material

- Instrument size

- Height 20mm (Miscellaneous data, confirmed according to the actual situation of the user)

- Sensors

- Thermocouple K

- Measurement range

- -200-1370℃

- Fine ℃

- ±0.3℃

Introduction

LN-80K Furnace Temperature Tracker for Aluminum Brazing is a product with excellent thermal insulation performance to ensure the safe and stable operation of the test system in high-temperature environments. It is capable of tracking multiple temperature profiles in all directions, providing reliable temperature mapping for aluminum brazing work. In conjunction with LEIEN furnaces and products, LN-80K can record the temperature status of furnaces and products throughout the process, generate accurate temperature profile analysis reports, and provide valuable data support for enterprises.

LN-80K Furnace Temperature Tracker for Aluminum Brazing can comprehensively analyze and calculate the collected data, help users accurately optimize the parameter settings of the furnace, improve product quality, and achieve the goal of stable and high yield and energy saving.

Scope of use

LN-80K is suitable for brazing furnace temperature test and tracking of aluminum products, including Water Tank brazing, radiator brazing, evaporator condenser brazing and other fields. It can monitor production temperature profiles and temperature data, helping companies improve product quality and reduce the number of reworked and scrapped products. It is a sharp tool to solve the key problems in the aluminum brazing process. By measuring the actual temperature profile of the workpiece in the furnace, it can optimize the brazing process, increase production efficiency and ensure product quality.

LN-80K

LN-80K