Rennes HC-4 Dacromet Furnace temperature tracker 4 channels 400 ℃ 1 hour

SELeiEn HC-4 Furnace temperature trackerSPEC

LeiEn HC-4 Furnace temperature trackerDetails

LeiEn HC-4 Furnace temperature trackerPacking list

- SKU

- NB046352

- Number of channels

- 4 channel

- Sensors

- Thermocouple K

- precision

- 0.5%

- Insulation box performance

- 400 ℃ for 60 minutes, 300 ℃ for 90 minutes

- Insulation box related indicators

- 400 ℃; 1-30 hours (customized according to the actual situation of the user)

- memory

- Each channel can record and store 16,000 pieces of data

- Sampling rate

- 1S, 2s, 3s, 4s, 5s, 6s, 10s, 20s, 30s, 1min, etc., can be selected by the user.

- Computer requirements

- Suitable for all computer systems

- Heat insulation box size (length × width × height)

- 280 × 160 × 100MM (300 ℃ for 1 hour)

Introduction

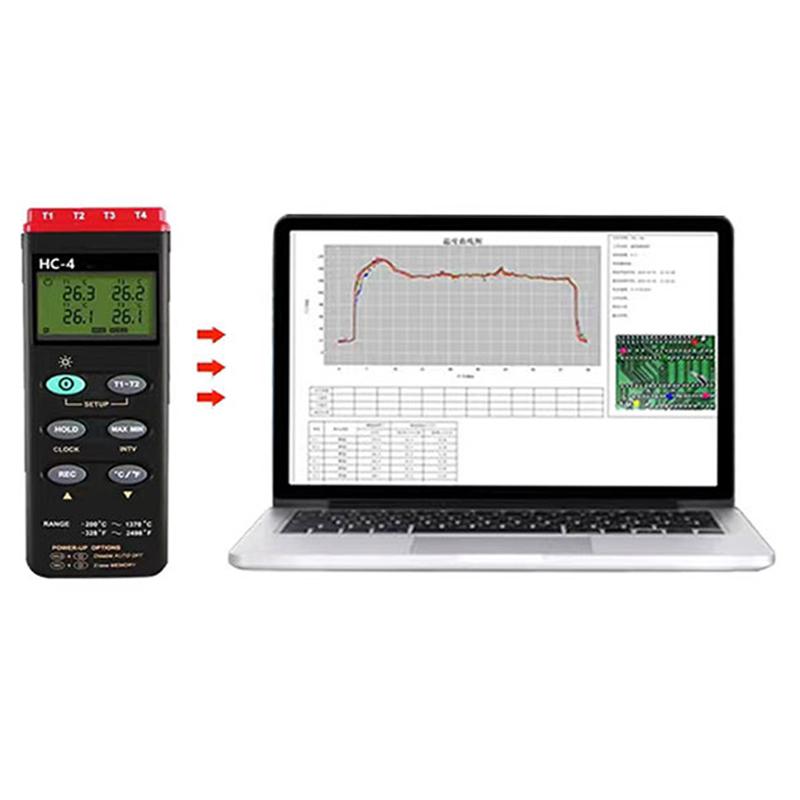

The HC-4 Dacromet Furnace Temperature Tracker is a furnace temperature tracker specially designed for Dacromet coating, designed to effectively test the baking temperature of Dacromet products. Its excellent thermal insulation allows it to perform temperature mapping in harsh thermal environments, guaranteeing the reliability of the test system. Without the need for tedious tests, the temperature of the heat treatment furnace and products can be tracked and monitored throughout the process to obtain valuable data. Using the resulting curve analysis reports, engineers are able to instantly understand the true temperature state of the product and furnace to provide guidance for operational optimization. By balancing temperature, time, and heating rates, line speed and product quality can be improved for efficient production.

Features

HC-4 Dacromet special furnace temperature tracker has the characteristics of high precision and high stability, and is a furnace temperature test record product. Equipped with a powerful software analysis system, it can save the data of the collected temperature values, and carry out synchronous analysis and processing of functional temperature and length, time, product function and other parameters. It can be tested multiple times, downloaded data once, and the digital display screen makes the status of each temperature measurement line clear at a glance, and the parameters are prefabricated and can be completed with only two key operations, with high precision and stability. The performance of the thermal insulation box is good, surpassing the imported products, ensuring the stable operation of the system.

HC-4

HC-4