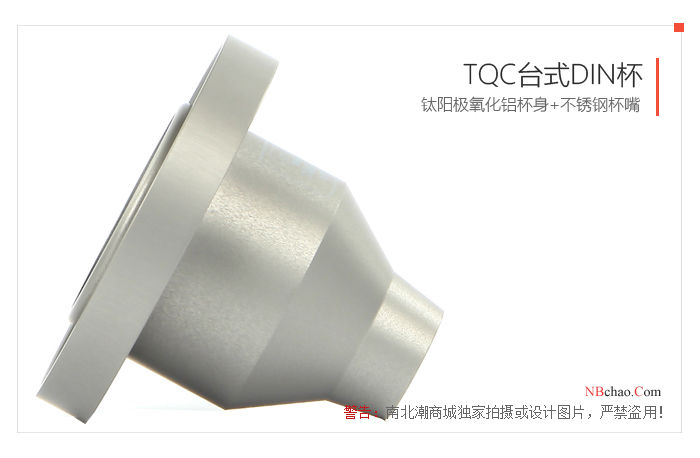

TQC VF2000 DIN cup, aluminum alloy Viscosity Cup 2mm

SETQC sheen VF2000 DIN CupSPEC

TQC sheen VF2000 DIN CupDetails

TQC sheen VF2000 DIN CupPacking list

- SKU

- NB004636

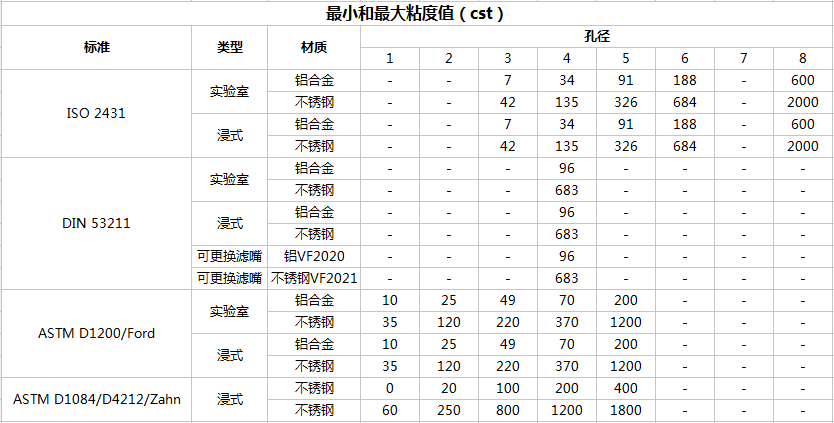

- Viscosity range

- 96~683cSt

- outflow time

- 25~150s

- Cup height

- 74mm

- Cup width

- 91mm

- Cup body material

- Titanium anodic oxidation aluminum

- Filter material

- stainless steel

- Applicable standards

- Approximate DIN 53211

- Certificate

- without

- Weight

- 212~214g

Introduction

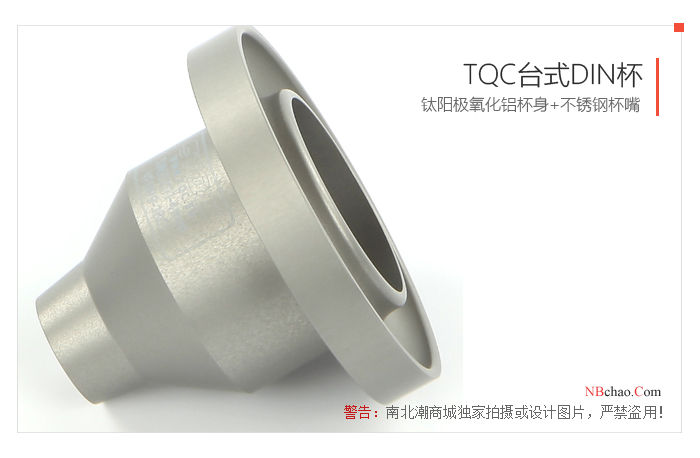

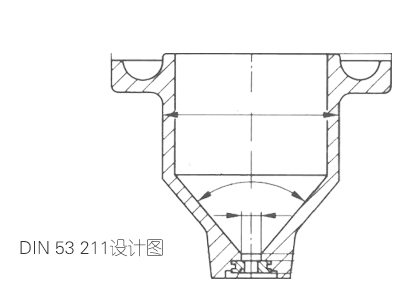

The Dutch TQC VF1999/2000/2001/2003/2004 DIN cup is a DIN benchtop flow Viscosity Cup with a filter that can be replaced, just buy a filter with a different diameterMeet the test of different viscosity ranges, save costs.DIN cups are suitable for testing the viscosity values of paints, varnishes and other liquids. rootVF1999/2000/2001/2003/2004 The body of the DIN cup is made of titanium anodized aluminum, and the spout holder and spout are made of stainless steel, which meets the DIN53211 standard.

Special aluminium DIN tabletop Flow Cup with stainless steel filter positioner for stainless steel filter with 1mm-8mm bore diameter. Stainless steel filters are sold to order separately. The internal dimensions of the interchangeable filter Viscosity Cup are similar to those specified in the DIN53211 standard.

The TQCdin cup can be used with a stand, and the bracket needs to be purchased separately.

Features

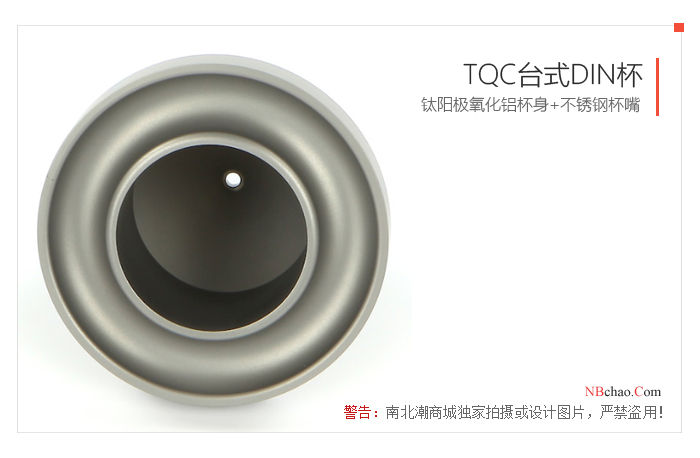

The cup mouth is designed with an annular groove to store spilled liquids.

The dimensions are designed so that they can be used with TQC viscous cup holders.

Easy to clean. There are no depressions in the structure of the cup walls and outflow holes that are difficult to clean.

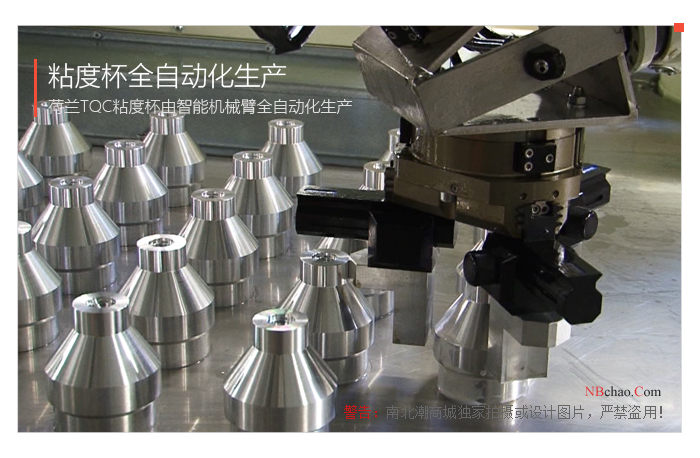

The production of TQC Viscosity Cups is subject to consistent quality control.

Each Viscosity Cup is engraved with a unique serial number.

Live shot

How to use:

DIN benchtop Flow Cups are used according to the standard, the temperature of the liquid to be measured is 25 degrees Celsius, and the temperature fluctuation needs to be minimized and cannot exceed +/- 0.2 degrees Celsius during the test. Adjust the temperature of the liquid to be measured if necessary.

According to the specification table and the expected viscosity range of the liquid to be measured, select the Viscosity Cup with the appropriate pore size.

Adjust the Viscosity Cup so that it is in a horizontal position (it is recommended to apply the Viscosity Cup holder and bubble level indicator). The outflow hole is then covered and the liquid to be measured is injected into the Viscosity Cup with the curved surface of the liquid above the rim of the cup.

Pipette the liquid curved section into the overflow ring with a glass drawer plate and close the DIN cup.

The distance between the DIN cup outflow hole and the liquid level of the recovered sample needs to be greater than 100 mm. Open the covered outflow hole and remove the glass drawer. The Timer Setting begins with the removal of the glass drawer and ends with the first interruption of the liquid flow beam.

Maintenance method:

It is especially important to clean the outflow hole to remove residue and avoid scratching its inner surface.

Although the Viscosity Cup is designed to be sturdy, it is a precision instrument and should not be dropped or impacted.

It needs to be cleaned after use.

Use a soft cloth to clean the Viscosity Cup, and do not use materials such as wire brushes or sandpaper. This is because this can be caused by corrosive cleaning agents

Long-lasting damage.

Do not tap directly on the spout when disassembling it. Use the pin rod that comes with the DIN tabletop Flow Cup against the spout before tapping with a weight such as a paperweight.

Before installing the spout, make sure the spout and Viscosity Cup are clean.

When not in use, return the DIN cup to the box.

We recommend calibration once a year.

Product shape diagram

TQC Model Selection

Take you to the Dutch TQC

VF2000

VF2000