HUXI HR-3000DRH Electric Lift Mulser 180L/3000rpm

SEHuXi HR-3000DRH Electric Lift MulserSPEC

HuXi HR-3000DRH Electric Lift MulserDetails

HuXi HR-3000DRH Electric Lift MulserPacking list

- SKU

- NB046463

- Motor type

- three-phase asynchronous motor

- Power

- 3000W

- Processing Capacity

- 180L (based on water)

- Rotation speed 2P

- 0-3000r/min

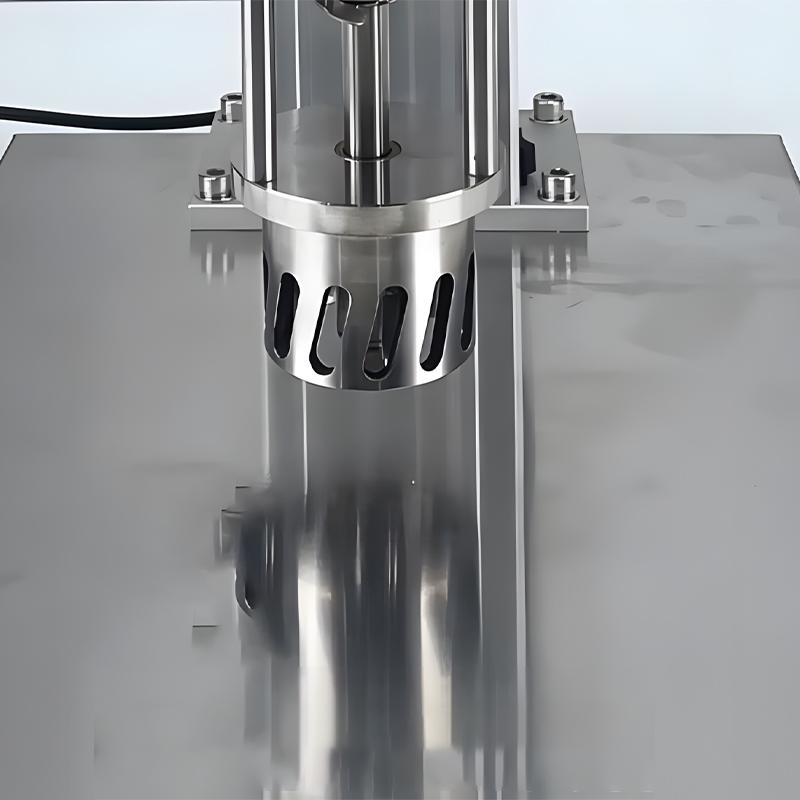

- rotating stator form

- Long hole type (standard)/round hole type/claw type

- Lifting method

- Electric lift

- Lifting stroke

- 600mm

- Voltage

- 220V/380V

- Bottom length and width

- 495*550mm

- Mulser head length

- 800mm

- Ground size

- 50-650mm

- Dimensions

- 850*620*1200mm

- Packaging Dimensions

- 870*840*1230mm

- Gross Weight

- 150kg

Applications

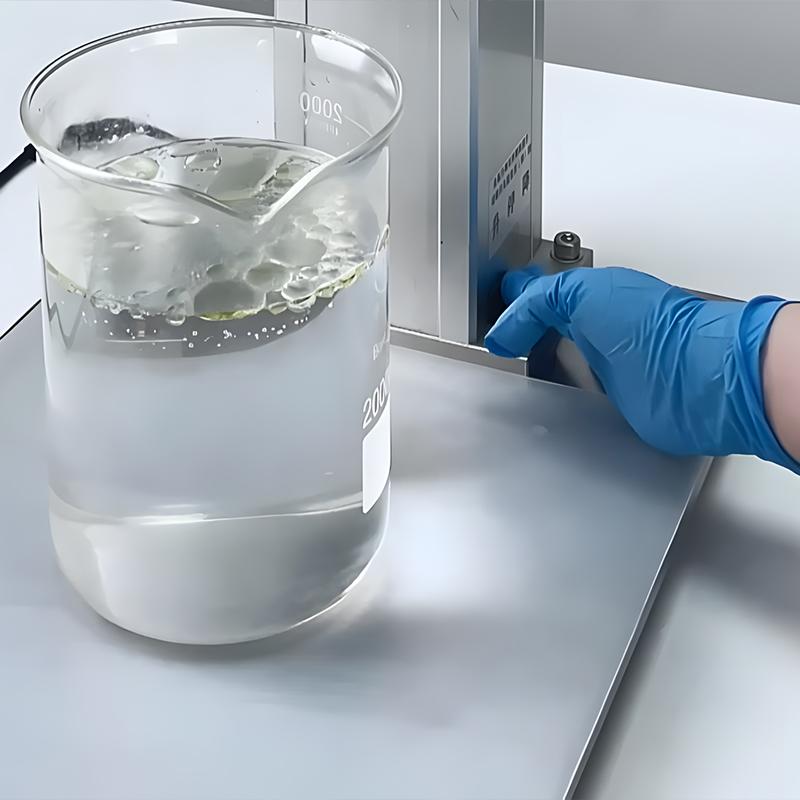

The laboratory electric lifting emulsifier is a laboratory equipment designed for small laboratory experiments. Through the method of mechanical external force, the particle size of liquid-liquid and solid-liquid materials is narrowed, so that one phase is evenly distributed into another or more phases, so as to achieve the effect of refinement, homogenization and dispersion, so as to form a stable liquid-liquid and solid-liquid dispersion system. The powerful motor rotates at high speed to create a vacuum between the rotor and stator, and the material is sucked in from the upper and lower parts of the rotor and stator. The large kinetic energy makes the rotor produce extremely high linear velocity, so that the material flies out after strong impact, crushing, centrifugal extrusion, liquid layer friction and strong shear between the rotor and stator gaps, and produces strong turbulence under the action of a variety of different directional forces. The material is repeatedly cycled under the appropriate amount of emulsifier and maturation process for a certain period of time to produce a stable emulsion. Application field: It is suitable for the dispersion, emulsification and homogenization of product materials in biological, food, coatings, inks, textile auxiliaries, cosmetics, lubricating oils, pesticides and other industries.

Features

High efficiency, can quickly distribute a phase uniform material into another or a variety of materials, to achieve the effect of refinement, homogenization, dispersion and emulsification, the final product is stable, not easy to stratify.

High machining accuracy, long life, the rotor stator is processed by forging materials and CNC numerical control machining center, the rotor stator gap is small, the shear fineness is good, the emulsion dispersion efficiency is high, and the cooling Mixing Tank is optional, the equipment can run for a long time and the temperature rise is low, and it can be automatically shut down according to the process timing emulsification time.

Various ways, compact equipment structure, electric lifting equipment atmosphere beautiful, labor-saving, installation-free, according to the viscosity of the material, choose and match the appropriate single/Mixing Tank, can meet the use of different Operating Conditions.

Strong non-standard, can be customized various types of non-standard products, such as explosion-proof type, airtight type, manual lifting type, etc., materials can be customized according to requirements SS304/SS316L/Hastelloy/titanium-molybdenum-nickel alloy and other materials. At the same time, different emulsifying heads can be customized according to the viscosity of the material to meet the needs of the laboratory or small batches.

304 stainless steel clad shell, fixed base.

Scope of application

It can be used by mixing solids and liquids, liquids and liquids to form solutions, colloids, suspensions or emulsions; Such as soup, dairy products, tissue homogenate, cosmetics, surfactants, asphalt, emulsifiers, oilfield chemicals and other more than 1,000 kinds of materials.

Rotator classification

Long bore stator head: Suitable for the rapid crushing of medium solids particles and the mixing of medium viscosity liquids, the long bore provides maximum area and good circulation for surface shearing.

Round bore stator head: suitable for general mixing or crushing of large particles, the round opening on this stator head provides better circulation in all stators and is suitable for handling higher viscosity materials.

Mesh stator head: suitable for low-viscosity liquid mixing, its shear rate is the largest, suitable for the preparation of emulsion and the crushing and dissolving process of small particles in liquid.

Claw stator head:The two-way suction method forms a two-way hyperbolic large circulation vortex in the container, which avoids the dead angle caused by the difficulty of inhaling the container materials, and the emulsification homogenization is more effective.

HR-3000DRH

HR-3000DRH