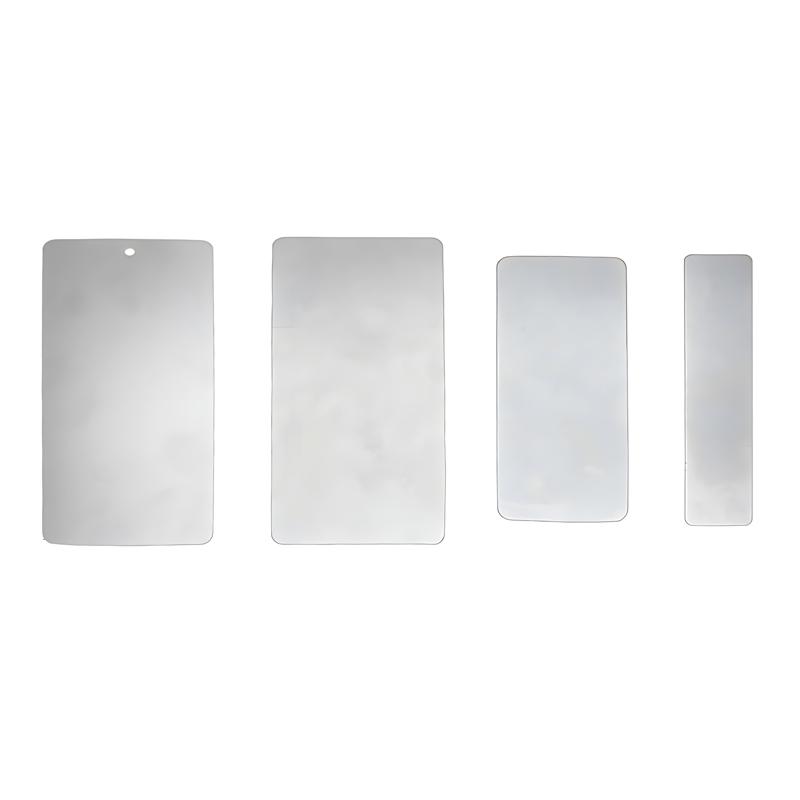

PUSHEN PS 2931/3 tinplate 150 * 70 * 0.28mm 200pcs/bag

SESpecification parameters 150 * 70 * 0.28mm, rounded corners non-porous, in line with standard GB/T 2520, surface preparation GB/T 9271, surface mass I, hardness grade T52, standard Film thickness 0.28mm.

$110.00/packet

PromotionLoading...

Coupon

Model:

Pushen PS 2931/3 Tackle iron plateSPEC

Pushen PS 2931/3 Tackle iron plateDetails

Pushen PS 2931/3 Tackle iron platePacking list

- SKU

- NB046981

- Specifications

- 150 * 70 * 0.28mm, rounded corners without holes/holes

- meet the standard

- GB/T 2520

- Surface preparation

- GB/T 9271

- Surface Mass

- Level I

- Hardness grade

- T52

- Film thickness

- 0.28mm

PS 2931/3

Tackle iron plate

Specification parameters 150 * 70 * 0.28mm, rounded corners non-porous, in line with standard GB/T 2520, surface preparation GB/T 9271, surface mass I, hardness grade T52, standard Film thickness 0.28mm.

Introduction

The performance test of industrial coatings, such as adhesion, hardness, impact, flexibility, drying time, bending, etc., is required to be prepared on tinplate when coating, and the amount of tinplate, hardness and surface treatment on the tinplate surface are the most important factors affecting the test results.

The tinplate plates provided by our company are all Baosteel tinplate, evenly tinned on both sides, and a variety of specifications are available for purchase, such as: curled earplate, rounded corners with or without holes, etc. The production volume of a single batch is 10w sheets, with stable quality and quality assurance.

FAQ

QI want to do Coating adhesion testing, which kind of tinplate is suitable?

A

PUSHEN PS 2931/3 tinplate is recommended. It adopts Baosteel tinplate, double-sided tin plating is uniform, and the surface mass is class I, which can ensure the accuracy and reliability of the Coating adhesion test results.

QDoes the surface preparation of tinplate affect the Coating test?

A

Yes, the tinplate surface of PUSHEN has uniform tin plating and Hardness T52, which meets the GB/T 9271 standard, which can effectively avoid the interference of surface factors and ensure the Repeatability of adhesion, Impact and other tests.

QI need a perforated tinplate for a bend test. Do you have any recommendations?

A

PUSHEN PS 2931/3 provides rounded corners with hole specifications, thickness 0.28mm, good flexibility, very suitable for bending, crimping and other tests, hole design is easy to fix operation.

Standard

PS 2931/3

PS 2931/3