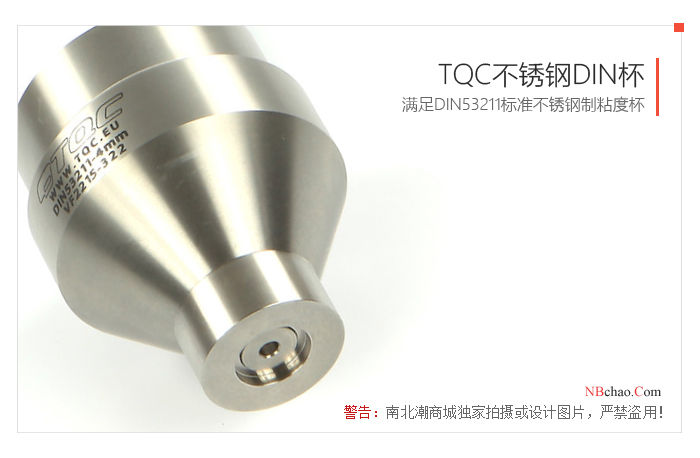

TQC VF2215 immersion Viscosity Cup stainless steel 4mm

SETQC sheen VF2215 Viscosity cupSPEC

TQC sheen VF2215 Viscosity cupDetails

TQC sheen VF2215 Viscosity cupPacking list

- SKU

- NB004700

- Viscosity range

- 96~683cSt

- outflow time

- 25~150s

- flow hole diameter

- 4mm

- Cup height

- 74mm

- Maximum width

- 63mm

- Total height

- 250mm

- Cup body material

- stainless steel

- Filter material

- stainless steel

- Handle material

- stainless steel

- Applicable standards

- DIN 53211

- Certificate

- without

- Weight

- 447~450g

TQC Viscosity CupIntroduction

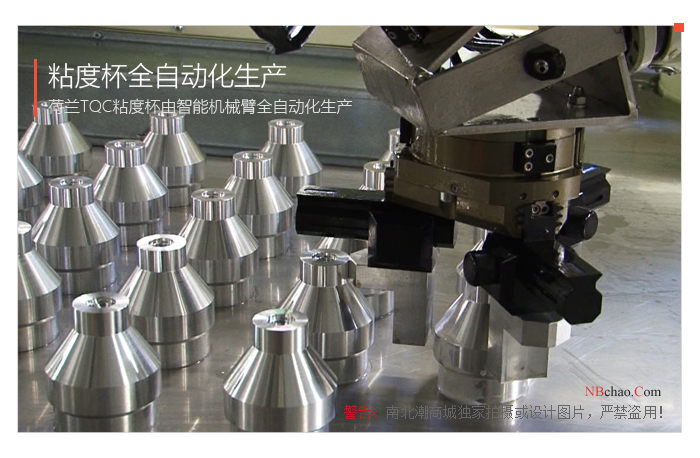

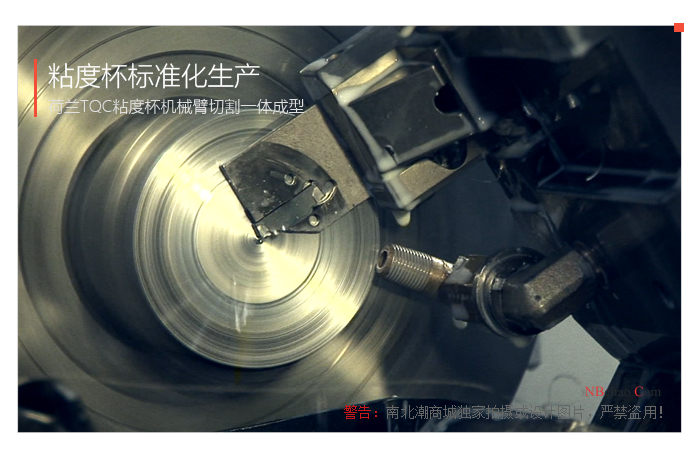

TQC immersion Viscosity Cups are made of stainless steel with VF2213, VF2215, VF2216 and VF2217 models, and the viscous cups are produced according to many international standards, which have been developed over the years, not only to specify the precise dimensional tolerances required in the process, but also to regulate their use and the recording of the data obtained. Viscosity cups were originally designed for rapid viscosity and consistency assessment of products that conform to or are close to Newtonian mechanical properties, such as paints, paints, inks, pigments.

TQC brand Viscosity Cups are produced under strict quality control procedures and are engraved with a unique serial number.

Parameters

| Model | Filter diameter | Flow time | Viscosity range |

| VF2213 | 2mm | ||

| VF2215 | 4mm | 25~150s | 96~683cst |

| VF2216 | 5mm | ||

| VF2217 | 6mm | ||

Other parameters | |||

| Material | stainless steel | ||

| standard | din 53211 | ||

| type | Immersion | ||

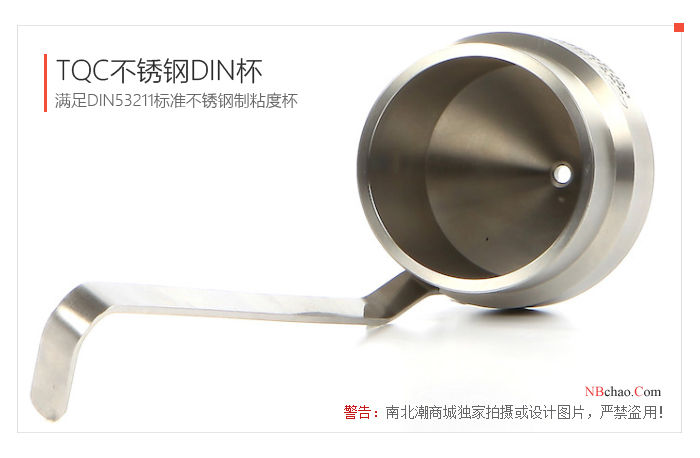

Viscosity measurement principle

DIN cups are used to test the concentration of paints, paints and other similar products. Through the process of liquid flowing out of the hole under the Viscosity Cup, the viscosity of the liquid is calculated and classified.

How to use:

It is recommended to purchase at least 1 standard Viscosity Cup with a calibration certificate to ensure accurate measurement results. During the measurement, the results of the standard product sample measured by the measuring Viscosity Cup and the standard Viscosity Cup are compared, and a corrected chart is drawn, so that the outflow time can be corrected through the graph, so as to obtain the correct test result.

Actual picture of the product

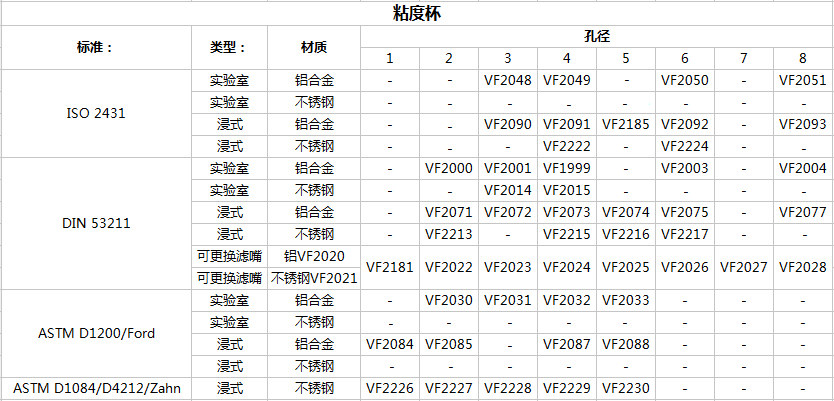

TQC Model Selection

Take you to the Dutch TQC

VF2215

VF2215