HUINUO TM2200Pro/1 Vacuum adsorption scraper Automatic Film Applicator Experiment High speed coater

SE-

HuiNuo TM2200Pro/03 drawdown blade vacuum adsorption high-precision coater effective Spreader area 400 * 400mm$ 5356.00SE

HuiNuo TM2200Pro/03 drawdown blade vacuum adsorption high-precision coater effective Spreader area 400 * 400mm$ 5356.00SE -

HuiNuo TM 2200/03 drawdown blade vacuum adsorption small coater effective Spreader area 400 * 400mm$ 4579.00SE

HuiNuo TM 2200/03 drawdown blade vacuum adsorption small coater effective Spreader area 400 * 400mm$ 4579.00SE -

CHINA TBJ-X1-DJ8 Detachable drawdown blade Vacuum adsorption Film Applicator Effective area 500 * 600mm$ 6289.00SE

CHINA TBJ-X1-DJ8 Detachable drawdown blade Vacuum adsorption Film Applicator Effective area 500 * 600mm$ 6289.00SE -

HUINUO TM2200Pro/02 drawdown blade vacuum adsorption Small Film Applicator Effective area 500 * 600mm$ 5978.00SE

HUINUO TM2200Pro/02 drawdown blade vacuum adsorption Small Film Applicator Effective area 500 * 600mm$ 5978.00SE -

Chinese TBJ-B1-DJ7 experimental drawdown blade coater bracket height adjustable, effective area 400 * 400mm$ 7066.00

Chinese TBJ-B1-DJ7 experimental drawdown blade coater bracket height adjustable, effective area 400 * 400mm$ 7066.00

HuiNuo TM2200pro/1 Automatic Film ApplicatorSPEC

HuiNuo TM2200pro/1 Automatic Film ApplicatorDetails

HuiNuo TM2200pro/1 Automatic Film ApplicatorPacking list

- SKU

- NB047141

- Coating method

- Drawdown blade

- Coating speed

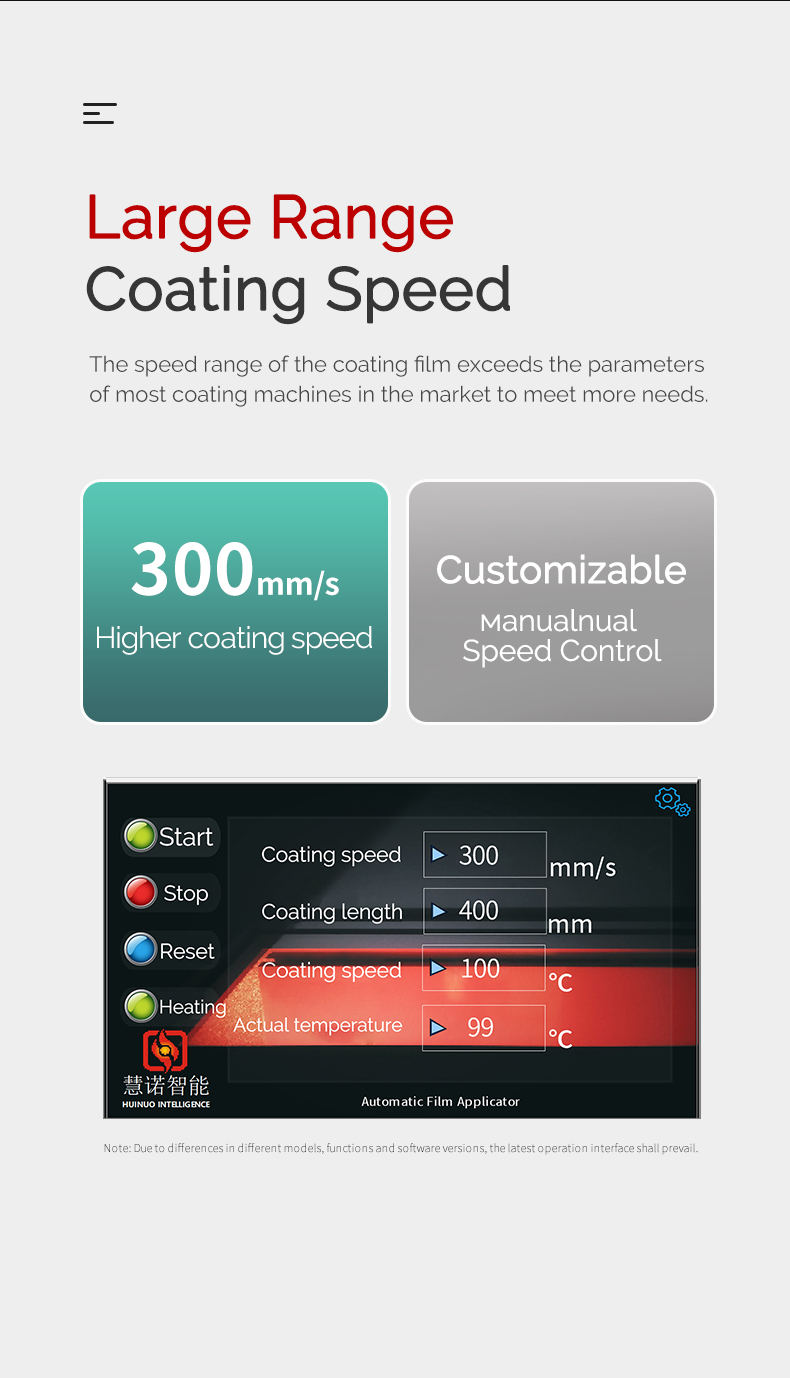

- 1~ 500Mm/s stepless speed regulation

- Wire speed Accuracy

- ±1%

- Coating table material

- Surface hard treatment aluminum alloy

- Precision stroke length

- ±2mm

- Effective coating Area

- 600*300mm

- Maximum test cardboard thickness

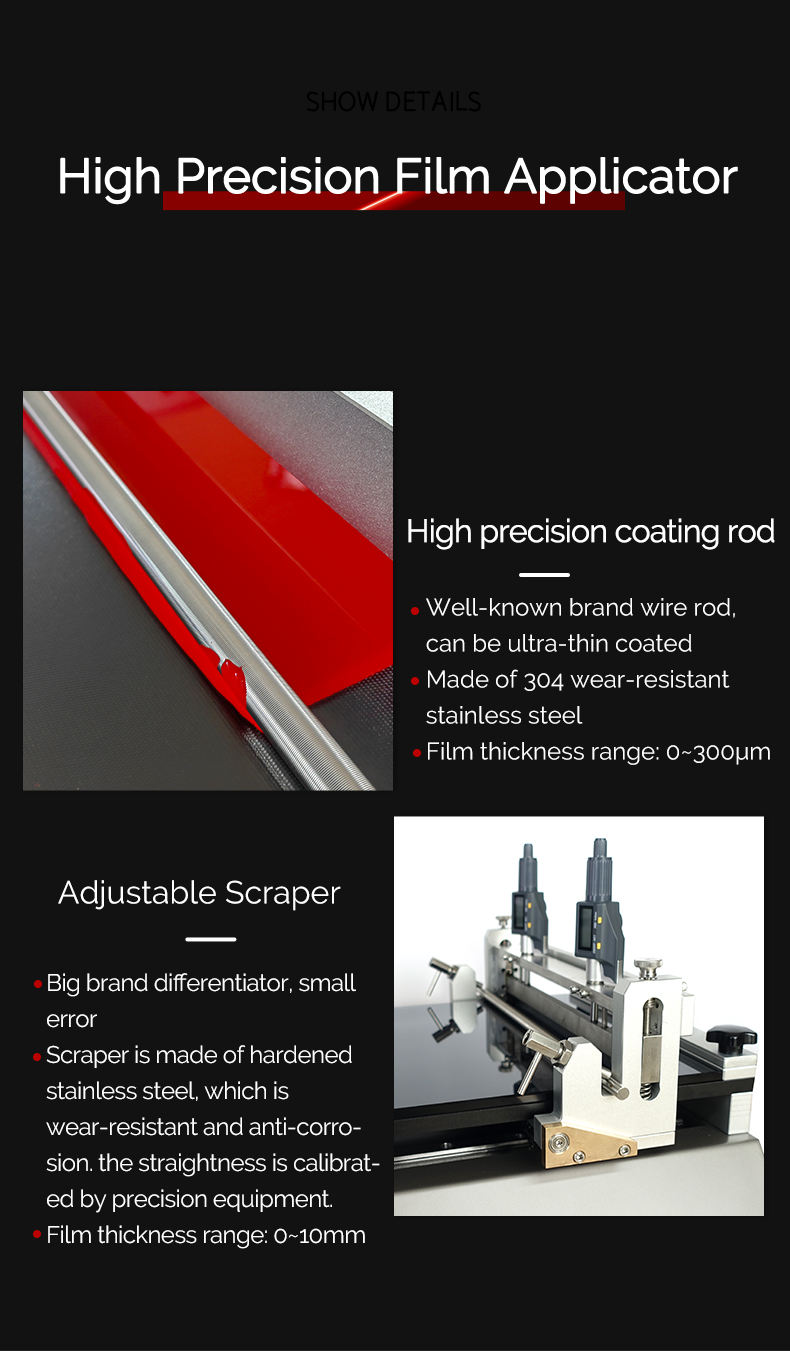

- 10mm

- Maximum test substrate thickness

- Drawdown blade 15mm, bar 10mm (more customizable)

- Vacuum Area

- 425*245mm

- Spreader maximum width

- 325mm

- Minimum length of coating rod

- 345mm

- Maximum diameter of coating rod

- Φ10mm

- Miscellaneous film applicator width

- 300mm

- Miscellaneous film applicator adjustable film thickness

- 0.01~ 13Mm (can be customized if required)

- Applicable standard

- ASTM D823

- Drive motor

- Servo motor

- Drawdown blade material

- Die steel

- Display

- 480 * 272 pixel 5 inch TFT display

- language

- Chinese

- Control mode

- Screen touch control

- Operating language

- Chinese (can be customized in English)

- Host Power Supply

- 220V/50HZ (can be customized 110V/60HZ)

- energy consumption

- 600W

- Dimension

- 860 * 440 * 430Mm (including differential head)

- Machine Weight

- 45Kg

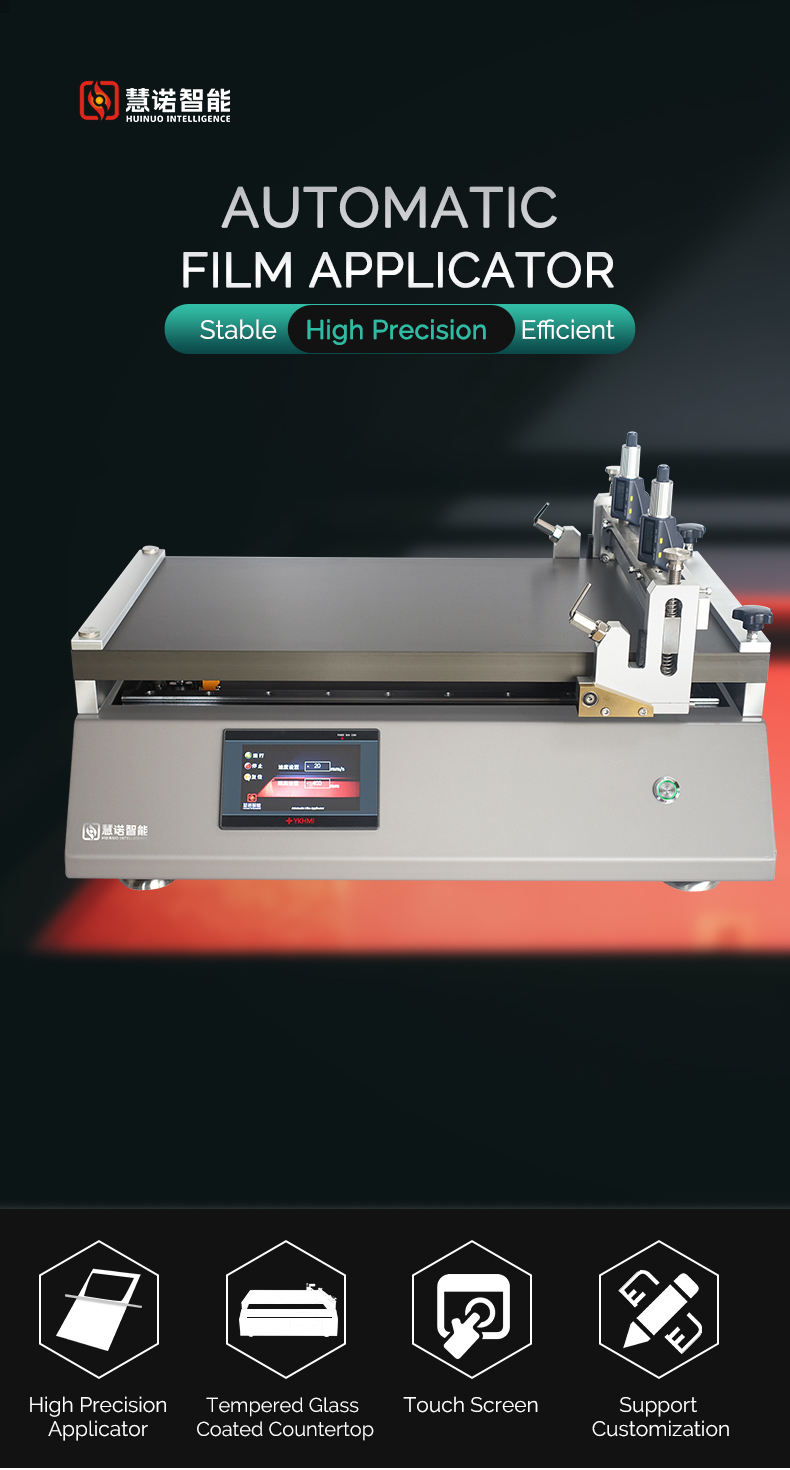

Overview

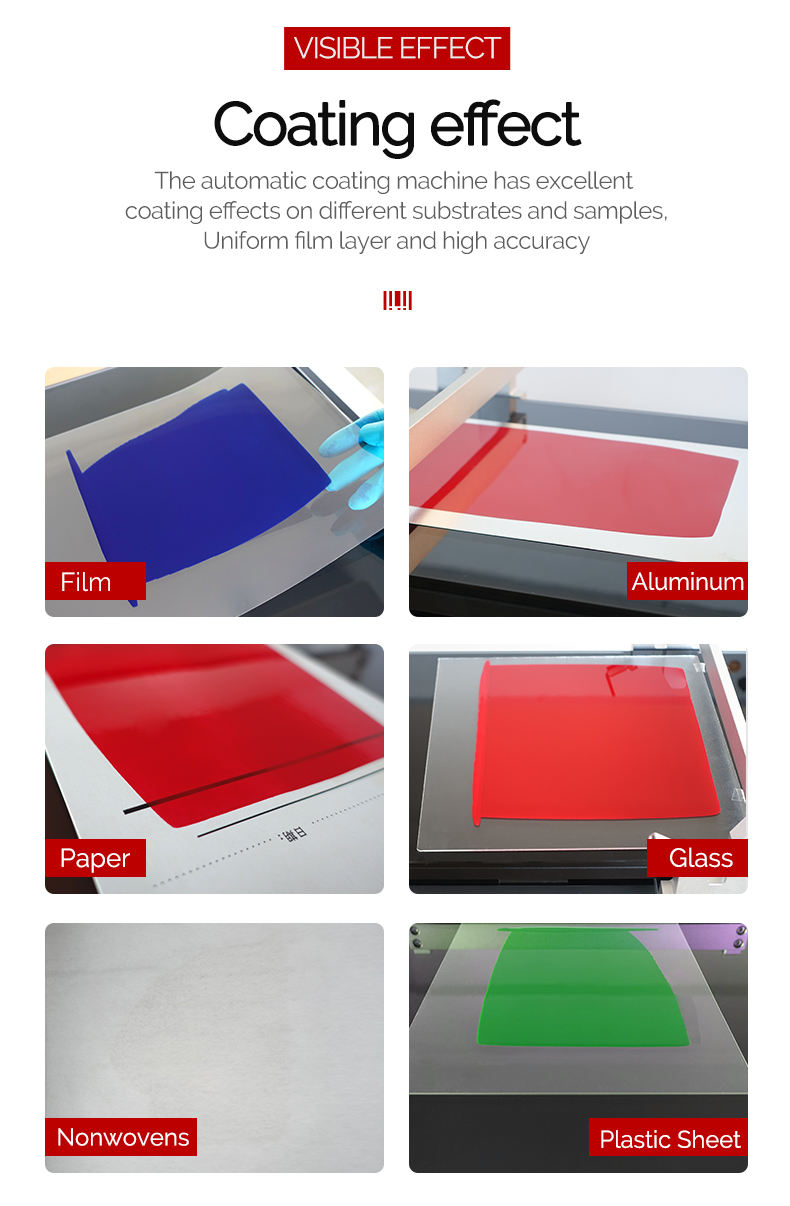

The automatic film coating machine is a device used to coat the film in the laboratory, replacing the manual coating film, and the coating film is carried out automatically, so as to improve the accuracy and efficiency of the coating film. The working principle of the experimental automatic film coater is to evenly coat the sample on the substrate by controlling the coating head and coating parameters to form the desired film.

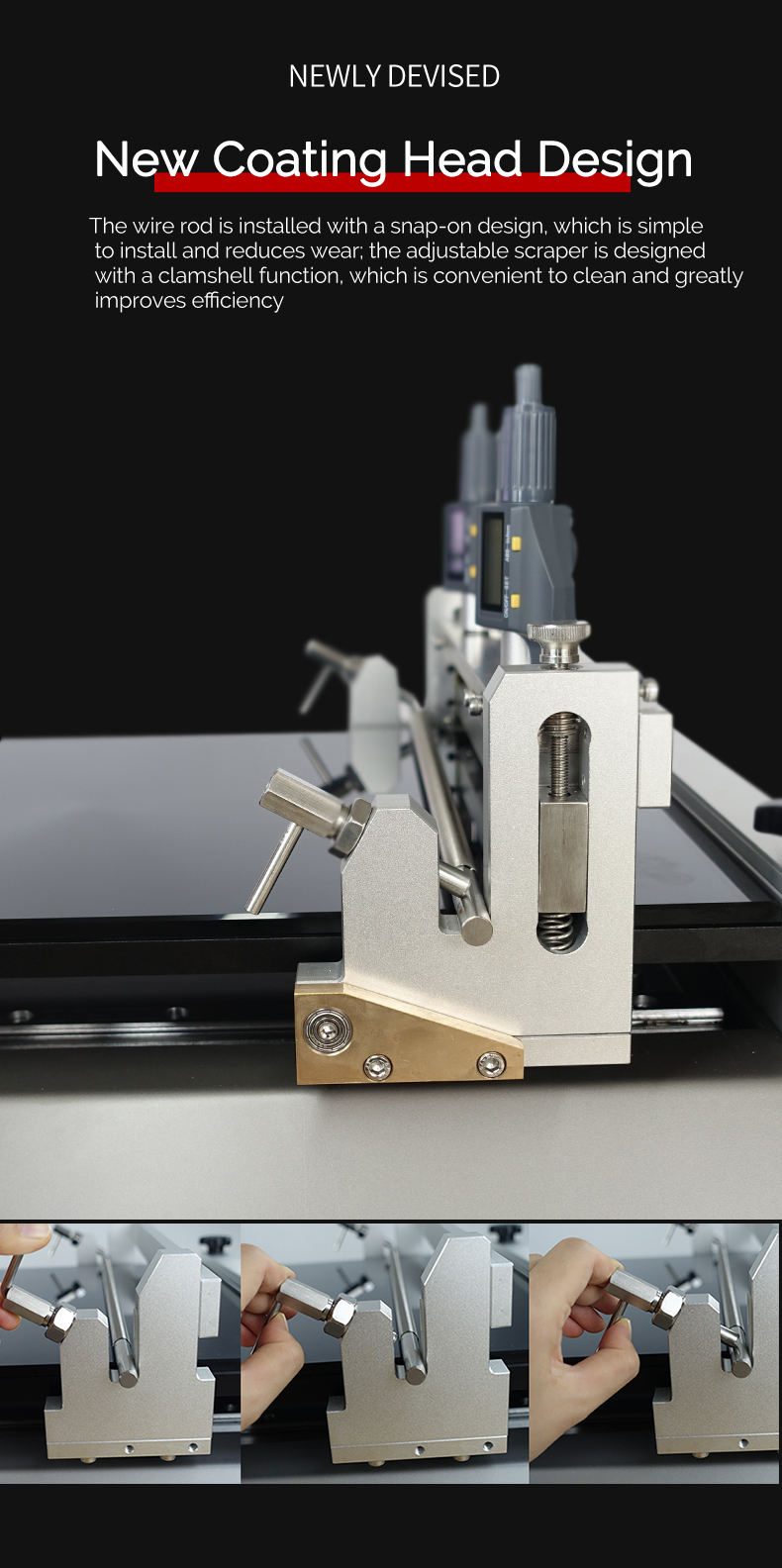

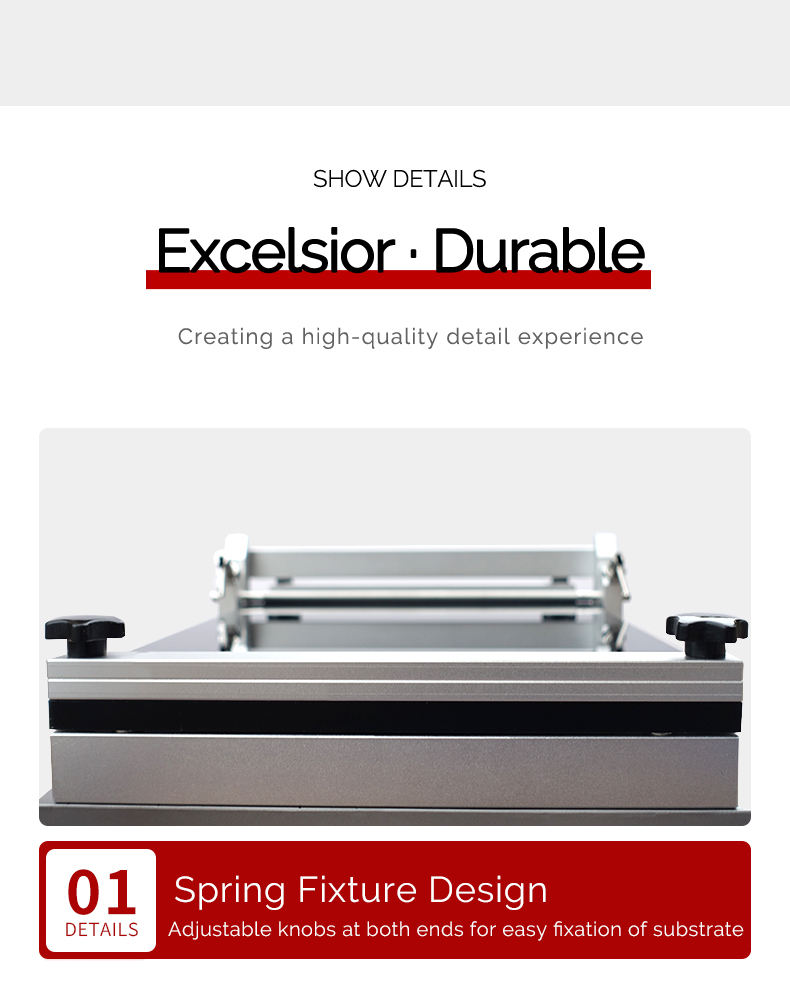

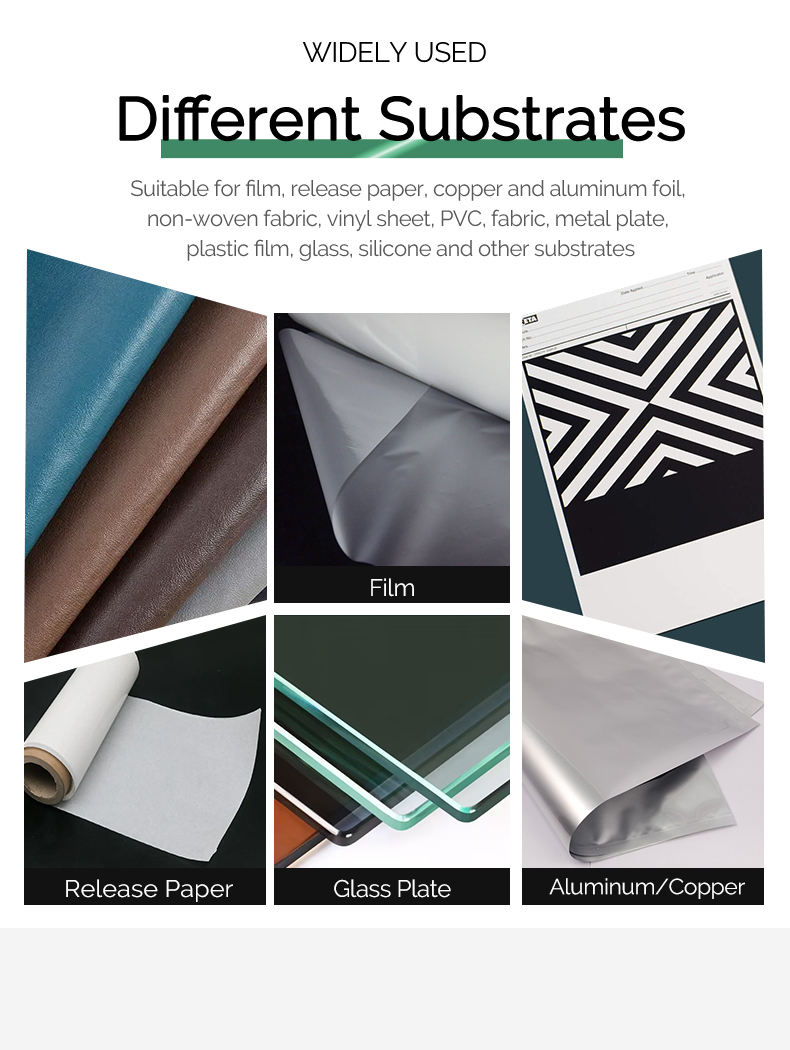

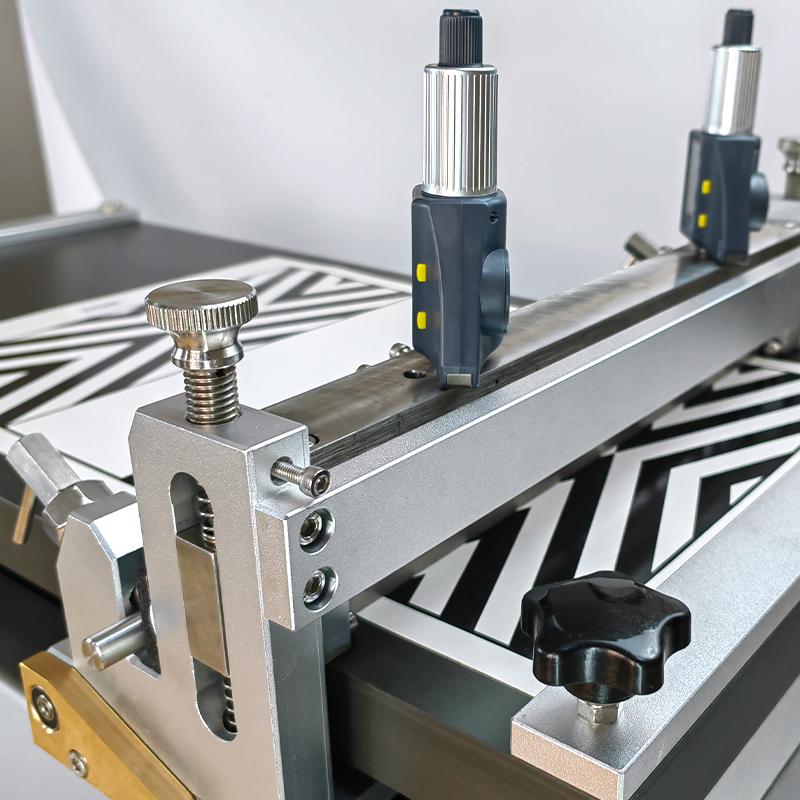

This coating machine is a scraper-type automatic coating testing machine.With vacuum adsorption function,The newly created wire rod installation method and clamshell scraper head greatly improve the coating efficiency, easy to clean, support speed control and coating length adjustment, suitable for high-precision automatic coating in the laboratory, and carry out film proofing in university research institutes, new materials, lithium batteries, glue, resin and other laboratories.

Applications

The film coating machine is suitable for coating samples of coatings, inks, paints, pastes, lithium batteries, pressure-sensitive adhesives, resins, glues, polymer materials, chemicals, etc., and can be scraped on films, release papers, aluminum foils and copper foils.

Features

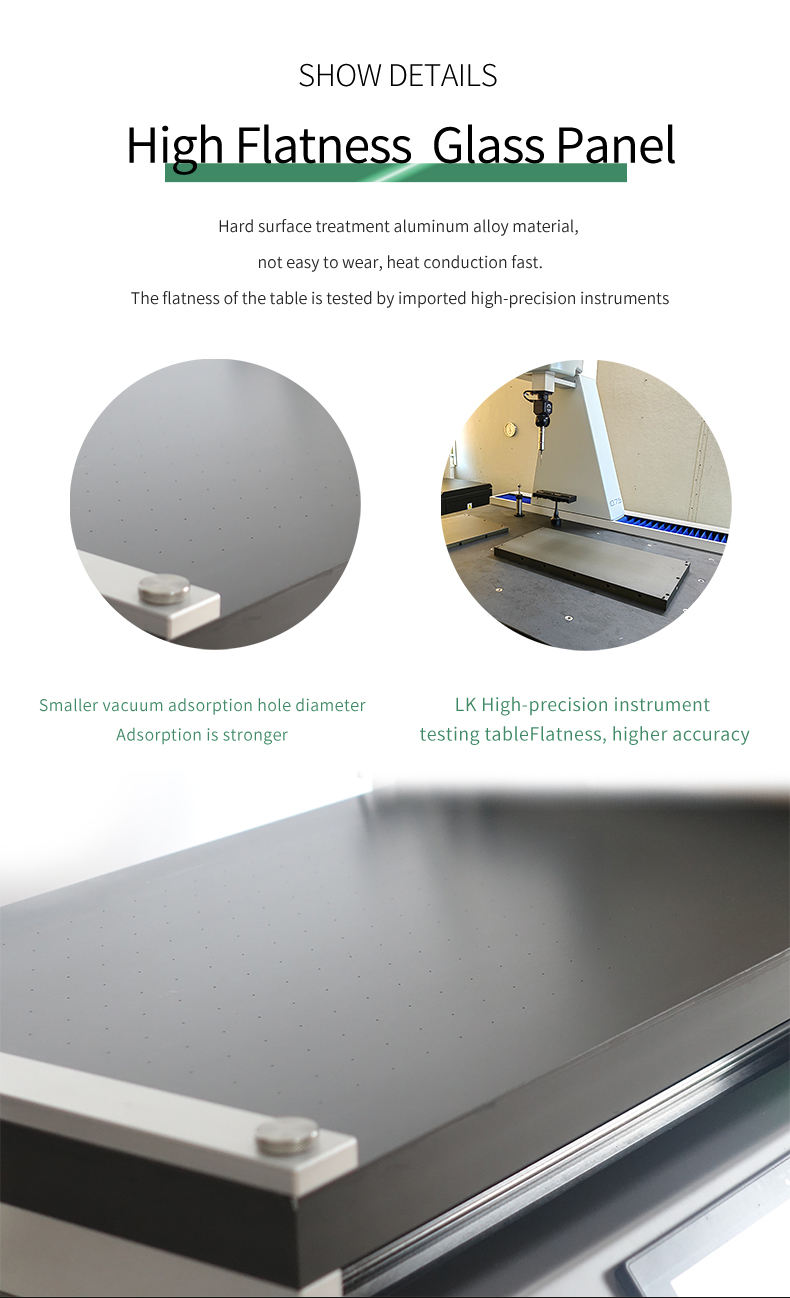

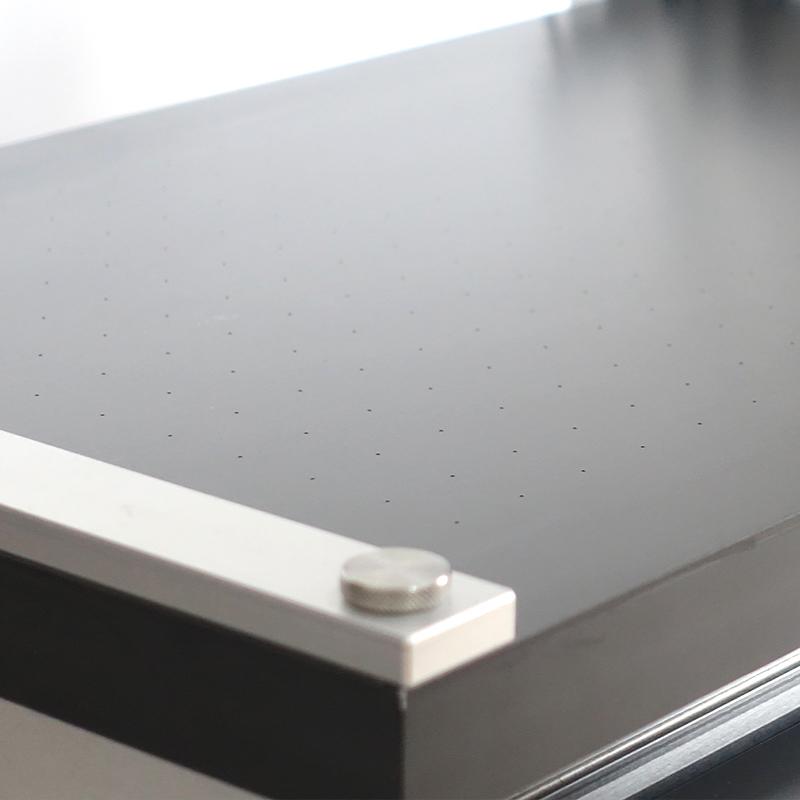

1) The surface is hard treated aluminum alloy table, with high hardness and wear-resistant, and the flatness of the table is tested by imported high-precision instruments.

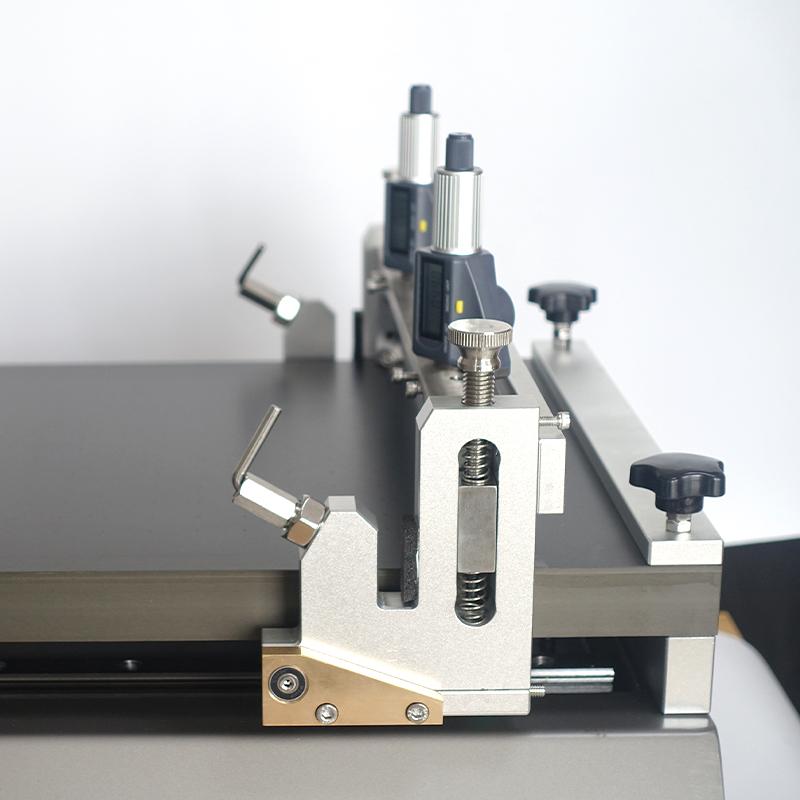

2) Big brand differential regulator, high film thickness control accuracy

3) With heating and vacuum adsorption function

4) Clamshell scraper design, quick and easy to clean

5) Touch screen control panel, easy to operate

6) The coating length and coating speed can be adjusted freely

TM2200pro/1

TM2200pro/1