TQC VF1844 cross-cut Tester Cross Hatch Cutter Set CC1000 Series

TQC sheen VF1844 Multivariate Cross Hatch CutterSPEC

TQC sheen VF1844 Multivariate Cross Hatch CutterDetails

TQC sheen VF1844 Multivariate Cross Hatch CutterPacking list

- SKU

- NB004735

- Number of teeth

- 6 teeth

- Tooth spacing

- 3mm

- Instrument material

- Vacuum hardened stainless steel, aluminum, rubber

- Application standard

- ISO 2409

- Applicable film thickness environment

- 121~250µm

- Appearance size

- 32*210*42mm

- Instrument Weight

- 331g

Introduction

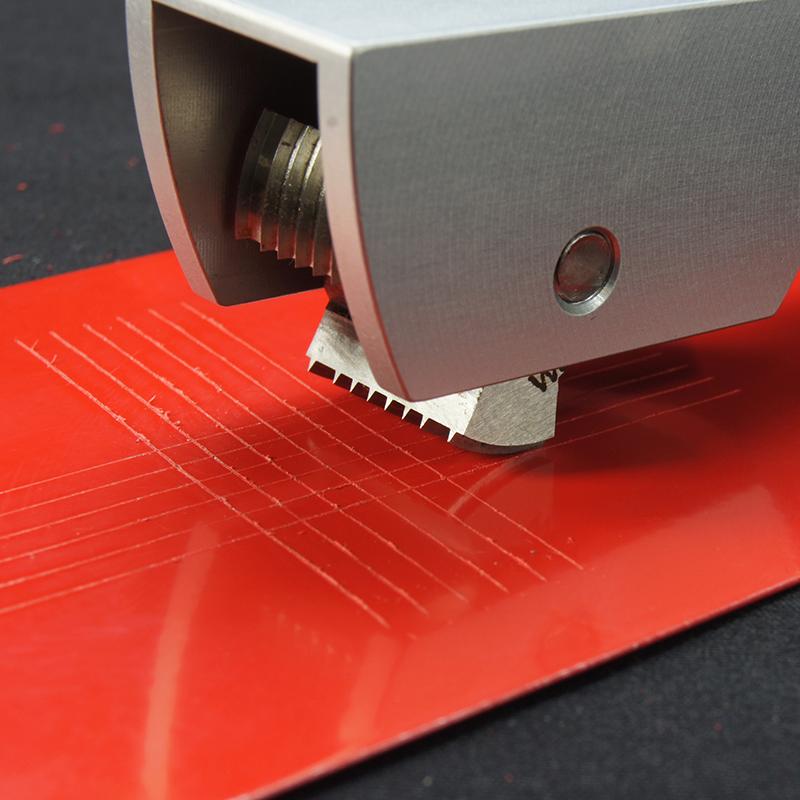

TQC CC1000 series multi-element cross-cutters include five models: VF1839, VF1842, VF1844, VF1846, and VF1847, corresponding to different coating film thicknesses. The CC1000 series scratcher has an automatically adjustable blade holder, which ensures a balanced pressure on the blade. This round cutter has eight cuts.

Product acessories

The tool box for the TQC CC1000 series multi-element grating Tester contains: a soft and easy-to-grip handle, a hard cutting blade (the blade is replaceable, see above), a nylon brush, an illuminated magnifying glass, and tape.

Real photos of CC1000 scratcher

Principle

TQC CC1000 series multi-element cross-hatch device uses the Principle of the cross-hatch method. The cross-hatch method is a test method for measuring the adhesion of dry coating on the surface. It uses a row of 6/11 blades between two outer conductors. Mark out 25/100 squares and determine the evaluation level through comparison. Measures the adhesion of a dry coat of paint to a substrate through a series of cuts. Cut out two parallel lines that cross at right angles to get 25 or 100 squares. Assess the area where the parallel lines intersect on a table and treat it briefly with a stiff brush or with tape on a hard substrate.

Comparison table of full range of adhesion Tester models

| TQC | Teeth | CC1000 | CC2000 | CC3000 | Suitable for thick film environment |

| cross-hatch adhesion Tester | - | Self-adjusting blade holder, round cutter with 8 cuts | Self-adjusting blade holder allows for easy changing of the cutter, with a rotating handle and no additional tools required | The blade holder maintains a fixed distance between the paint surface and the two auxiliary wheels, and the cutting depth can be accurately adjusted to ensure repeatability. | - |

| ISO2409/ASTM D3359 | 1 | VF1839 | SP1690 | SP1680 | ISO2409: 0~60μm (solid substrate) ; ASTM D3359: 0~50μm (solid substrate) |

| ISO2409 / ASTM D3359 | 2 | VF1842 | SP1691 | SP1681 | ISO2409: 0~60μm (soft substrate), 61-120μm (firm substrate ) ; ASTM D3359: 50~125 μm (solid substrate) |

| ISO/DIN2409 | 3 | VF1844 | SP1692 | SP1682 | 121-250μm (solid substrate ) |

| ASTM 3359ï¼2009 | 1 | VF1846 | SP1699 | SP1683 | 0~50μm (solid substrate ) |

| ASTM 3359 is less than 2009 | 1.5 | VF1847 | SP1700 | SP1684 | 50~125μm (solid substrate ) |

Take you into the Dutch TQC

- 1JJF 2163-2024《Calibration Specification for Paint Film Scribers》

- 2SJ 20910A-2018《General specification for powder spraying coating》

- 3GB/T 9286-2021《Paints and varnishes—Cross-cut test》

- 4HG/T 20720-2020《Construction and acceptance specification of waterborne anti-corrosion coatings for steel structures in industrial buildings》

- 5HG/T 5776-2020《Water-based coatings for surface of rubber sealing products》

- 6HG/T 5187-2017《Automobile axle spring anticorrosive primer》

- 7HG/T 5299-2018《Optical polyethylene terephthalate(PET) transparent hardening film for indium tin oxide(ITO)》

- 8HG/T 3829-2006《Floor coatings》

- 9ASTM D3359-2023《Standard Test Methods for Rating Adhesion by Tape Test》

- 10GB/T 9755-2014《Synthetic resin emulsion coatings for exterior wall》

VF1844

VF1844