YIBAI CTG-600 Coating Thickness Gauge dual-use Film Thickness Gauge

SE-

DONGRU DR280 dual-use Coating Thickness Gauge$ 319.00SE

DONGRU DR280 dual-use Coating Thickness Gauge$ 319.00SE -

DONGRU DR380 portable Film Thickness Gauge magnetic and eddy current Thickness Gauge$ 416.00SE

DONGRU DR380 portable Film Thickness Gauge magnetic and eddy current Thickness Gauge$ 416.00SE -

CHINA CTG-802-1500FN Split iron-aluminum dual-use Coating Thickness Gauge (standard)$ 236.00SE

CHINA CTG-802-1500FN Split iron-aluminum dual-use Coating Thickness Gauge (standard)$ 236.00SE -

CHINA CTG-802-1500FNV split iron-aluminum dual-use Coating Thickness Gauge (standard/large V type)$ 248.00SE

CHINA CTG-802-1500FNV split iron-aluminum dual-use Coating Thickness Gauge (standard/large V type)$ 248.00SE -

CHINA CTG-802-3000FN Split iron-aluminum dual-use Coating Thickness Gauge (large range)$ 248.00SE

CHINA CTG-802-3000FN Split iron-aluminum dual-use Coating Thickness Gauge (large range)$ 248.00SE

YiBai CTG-600 Coating Thickness GaugeSPEC

YiBai CTG-600 Coating Thickness GaugeDetails

YiBai CTG-600 Coating Thickness GaugePacking list

- SKU

- NB047362

- Measurement range

- 0~1500μm

- resolution

- 0.1μm|1μm

- minimum radius of curvature

- Convex: 1.5mm

- margin of error

- ±2%

- thinnest matrix

- 0.3mm

- display

- LCD dot matrix LCD screen

- Power Supply

- 2 AA batteries

- applicable occasions

- Magnetic nonmagnetic coatings on substrates

- Operating Environment

- Temperature -10-50 ℃, Humidity < 80%

- size

- 101*61*26mm

- Weight

- 54G (without battery)

- Measurement principle

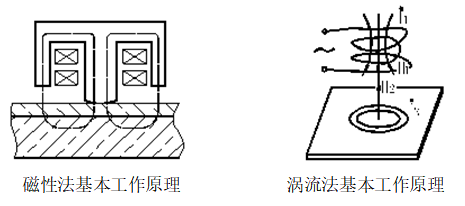

- Magnetic Induction + eddy Current

Yibai CTG-600 split coating Thickness Gauge has the functions of backlight, large-screen digital display, single-point and multi-point calibration, and this product is resistant to high-low temperatures, drops, probe wear-resistant (more than 500,000 times), good test stability, fast test speed, and suitable for various measurement environments. Its technical parameters are in line with national and international standards.

The FE function detects the thickness of non-magnetic coatings on all magnetic substrates, such as lacquer applied to steel, iron, powder coating, plastic, porcelain, chromium, copper, zinc, etc.

The NFe function detects the thickness of the insulating coating on all non-magnetic substrates, such as lacquer, plastic, porcelain, etc. These coatings must be applied to a non-magnetic metal substrate such as aluminum, copper, brass or stainless steel.

function

●Measurement method: F magnetic induction, N eddy current

●Spring-loaded guide bush probe with wear-resistant carbide probe can ensure that the probe has constant compression force and stable sampling value when measuring on hard or rough surfaces;

●It can quickly and automatically identify the magnetic substrate;

●High precision, good stability, can measure 1-5μm ultra-thin coating;

●The measurement speed can reach 0.3 seconds/time;

●Large-screen digital display is clearer;

●Two shutdown modes: manual shutdown mode and automatic shutdown mode;

●Wide measurement range and high resolution;

●Digital backlight display, no parallax, suitable for night use;

●Measurement mode: single measurement/continuous measurement;

●It has the function of converting metric and imperial units to achieve μm/mil conversion;

●Newly designed shell and internal structure to enhance the beauty, drop resistance and impact resistance of the product;

●The light touch measurement accuracy is good.

- 1GB/T 13448-2019《Test methods for prepainted steel sheet and strip》

- 2GB/T 13448-2006《Test methods for Prepainted Steel Sheet》

- 3ISO 4042-1999《Fasteners -- Electroplated Coatings》

- 4QC/T 484-1999《Automotive paints coatings》

- 5JB/T 5673-1991《General technical conditions for painting agricultural and forestry tractors and machinery》

CTG-600

CTG-600