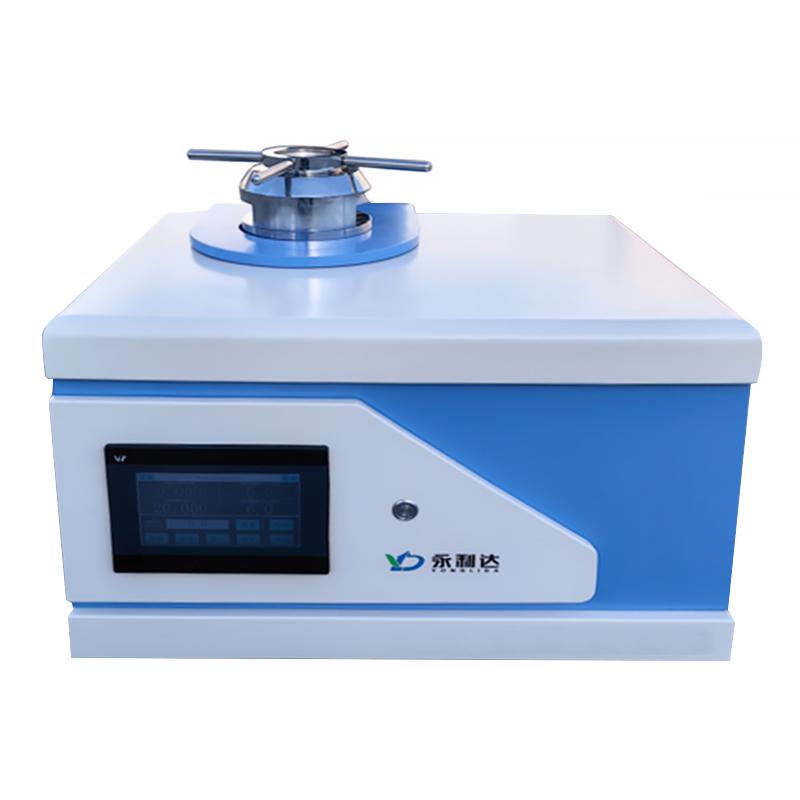

YONGLIDA YLD-6810 Digital Cupping test machine

SESinking speed 0.01-0. 70mm/s, stroke length 0-12mm/s, maximum panel width 105mm, maximum panel thickness (steel) 0.8mm, maximum speed (steel panel) 0.6mm/s, maximum panel thickness (aluminum) 1.2mm, maximum speed (aluminum panel) 0.7mm/s, +/- 1% of speed accuracy setting speed, maximum sinking force 5000N, indenter width (ball) φ 20mm, mold diameter 27mm.

$2029.00/set

PromotionLoading...

Coupon

Model:

YongLiDa YLD-6810 Cupping test machineSPEC

YongLiDa YLD-6810 Cupping test machineDetails

YongLiDa YLD-6810 Cupping test machinePacking list

- SKU

- NB047380

- indentation rate

- 0.01-0.70mm/s

- stroke length

- 0-12mm/s

- Maximum panel width

- 105mm

- Maximum panel thickness (steel)

- 0.8mm

- Maximum speed (steel panel)

- 0.6mm/s

- Maximum panel thickness (aluminum)

- 1.2mm

- Maximum speed (aluminum panel)

- 0.7mm/s

- Speed Accuracy

- +/- 1% of the set speed

- Maximum crushing force

- 5000N

- Die diameter

- 27mm

- size

- 390*355*450mm

- Net Weight

- About 29kg

- Display

- Color touchscreen

- security

- panic button

YLD-6810

Cupping test machine

Sinking speed 0.01-0. 70mm/s, stroke length 0-12mm/s, maximum panel width 105mm, maximum panel thickness (steel) 0.8mm, maximum speed (steel panel) 0.6mm/s, maximum panel thickness (aluminum) 1.2mm, maximum speed (aluminum panel) 0.7mm/s, +/- 1% of speed accuracy setting speed, maximum sinking force 5000N, indenter width (ball) φ 20mm, mold diameter 27mm.

Introduction

YLD-6810 digital cup protrusion testing machine is suitable for evaluating the coating of steel plate, pigment varnish and related products (single layer or supporting coating) under the experimental method specified in the standard, and carry out the depression test, so that after the gradual deformation, the steel plate and coating are resistant to cracking or anti-separation from metal materials, and the steel plate and coating pass or fail to pass; The depth of indentation can also be gradually increased to determine the minimum depth at which the steel plate, coating has just cracked, or has begun to detach from the substrate.

Applicable Standards

GB/T9753 "Colorbut and varnish - Cupping test"

FAQ

QTest the cracking performance of steel plate coatings, what instrument should I use?

A

YLD-6810 digital Cupping test machine through the standard depression test, detect whether the steel coating cracking or from the substrate during the deformation process, in line with GB/T9753 national standard, suitable for Quality control laboratory use.

QCan this testing machine measure Aluminum Panel? How to choose the speed?

A

Aluminum Panel can be measured, with a maximum thickness of 1.2mm. The recommended speed for Aluminum Panel testing is 0.7mm/s, and the instrument speed accuracy is +/- 1%, which can ensure accurate and reliable test results and help you complete material performance evaluation.

QTest the cracking performance of steel plate coatings.

A

YLD-6810 digital Cupping test machine is specially used to evaluate the anti-cracking and anti-separation performance of steel plates and coatings in the depression test. It conforms to the GB/T9753 standard and can accurately determine the minimum depth of cracking of coatings.

QCan this instrument measure Aluminum Panel? How to operate it?

A

Test aluminum plate, up to 1.2mm thickness. Set the sinking speed through the touch screen (Aluminum Panel up to 0.7mm/s), the punch and the die cooperate with the sinking sample, display the depth change in real time, and automatically record the critical value of coating cracking or separation.

Knowledge

- 1Operation method and precautions of cupping instrument

- 2Cupping Tester measurement of coating bond strength

- 3Cupping Testing Machine Test Coating Cupping Test

- 4Film Cupping Test: an important indicator of coating mass and performance

- 5Cupping test and its role in Coating evaluation

- 6How to use the cupping Tester

- 7Preparation of coating powder

- 8Failure analysis of galvanized sheet stamping by cupping testing machine

陈思琪,王雷刚,黄瑶 - 《《基于杯突试验的镀锌板冲压成形失效分析》》

- 9Cracking resistance of coatings: Cupping test

Standard

- 1JJF 1297-2011《Program of Pattern Evaluation of Cupping Testing Machine》

- 2BS EN ISO 1520-2006《Paints and varnishes. Cupping test》

- 3JJG 583-2010《Verification Regulation of Cupping Testing Machine》

- 4HB 6140.5-1987《Test method for formability of sheet metal - Cupping test》

- 5JB/T 7408-2013《Cupping testing machines.Specification》

- 6YS/T 419-2000《Aluminum and aluminum alloy cupping test method》

- 7HB 5179-1981《Metal cupping test method》

- 8NF 《Coil coated metals - Test methods - Part 6 : adhesion after indentation (cupping test)》

- 9 10671-2015《Paints and varnishes - Cupping test》

- 10GB/T 22638.11-2023《Test methods for aluminum and aluminum alloy foils—Part 11: Determination of mechanical properties》

YLD-6810

YLD-6810