DUBAN DB25-204SPT 5KN Ponzi Tensiometer, Range +/- 4900N

SEDuban DB25-204SPT 5KN Ponzi tensioMeterSPEC

Duban DB25-204SPT 5KN Ponzi tensioMeterDetails

Duban DB25-204SPT 5KN Ponzi tensioMeterPacking list

- SKU

- NB047458

- resolution

- 0.01kgf (<100kgf)、0.1kgf (≥100kgf);0.1N (<1000N)、1N (≥1000N);0.1Lbf (<1000Lbf)、1Lbf (≥1000Lbf)

- Precision

- Level 0.5

- Accuracy

- +/- 0.5% FS (range) +/- 1 digital peak

- unit

- kgf, N, Lbf

- Measured value

- Peak, instantaneous value

- show

- Four large LCD, forward and reverse dual display

- shutdown mode

- 10 minutes automatic shutdown or manual shutdown

- Backlight

- Blue Backlight

- allowable load

- 150% F.s (buzzer alarm when it exceeds 110% F.s)

- Power Supply

- 2 AA batteries, or 5V DC Power Supply

- Operating temperature

- 0°C~40°C

- Operating humidity

- < 80%

- Operating Environment

- No source and corrosion medium around

- Host size

- 199mmx76mmx37mm

- Sensors size

- 140mmx65mmx105mm

Introduction

Lateral pressure tensiometer is a kind of digital tensiometer newly designed and developed. It has the advantages of high precision, easy operation and easy to carry. It also has a peak hold test mode, which is convenient for Testers to use, and various test benches and fixture combinations can form testing machines for different purposes. There are many specifications of the side pressure tensiometer for users to choose, and users can choose the corresponding specifications of the instrument according to the force value of the product to be tested. The scientific use test range is 10%~100% of the full scale, and the metrology department recommends not to use the part below 1% of the full scale. At the same time, after the instrument and the object to be tested in place, press the ZERO button to clear to eliminate the weight of the fixture, etc.

The side pressure Tension Tester is a special instrument for measuring the rope tension of wind towers, signal transmission towers, power transmission systems, etc. It has the advantages of easy operation and easy carrying. It also has a variety of test modes, which is convenient for Testers to use.

Features

High precision and high resolution.

Digital display, no parallax.

N (Newton), kg (kg), lb (pound) three units of measurement are available and converted to each other.

Peak hold function. Hold the peak display until it is manually cleared.

Can be powered by alkaline batteries; It can also be connected to a 5V DC power supply.

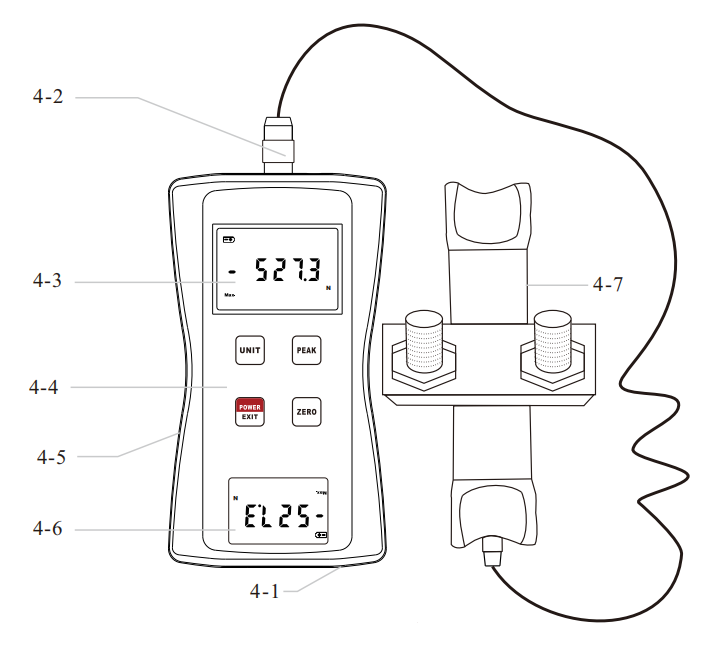

Product structure diagram

4-1 Power Interface:It can be connected to a 5V DC power supply to achieve DC power supply.

4-2 Sensor Plug:It is used to connect the host computer to the sensor

4-3 Display A:It is used to display measurement readings, units of measurement, prompts during operation, etc.

4-4 Operation button area:All the operation buttons are distributed, and the key operation of the entire instrument is completed here.

4-5 Battery box on the back: The place where the battery is installed to achieve battery power.

4-6 Display B: Used to display measurement readings, measurement units, prompt information during operation, etc. Its main function is to facilitate the taking of readings in multiple directions.

4-7 Measurement sensor: It can convert the received force information into an electrical signal and transmit it to the host computer.

DB25-204SPT 5KN

DB25-204SPT 5KN