DUBAN DB25-204M Muscle Strength Tester Measurement range +/- 490N

SEDuban DB25-204M Muscle strength TesterSPEC

Duban DB25-204M Muscle strength TesterDetails

Duban DB25-204M Muscle strength TesterPacking list

- SKU

- NB047459

- Measurement range

- ±50kgf、±490N、±110Lbf

- resolution

- 0.01kgf、0.1N、0.1Lbf

- Backlight function

- With backlight

- Accuracy

- +/- 0.5% FS (range) +/- 1 digital peak

- unit

- kgf, gf, N, Lbf

- Measured value

- Peak, instantaneous value

- show

- Four large LCD, forward and reverse dual display

- shutdown mode

- 10 minutes automatic shutdown or manual shutdown

- allowable load

- 150% F.s (if it exceeds 110% F.s, there will be a beep alarm)

- Power Supply

- 2 AA batteries or 5V DC Power Supply

- Operating temperature

- 0~40°C

- Operating humidity

- <80%

- Operating Environment

- No source and corrosion medium around

- instrument size

- 199mm*76mm*37mm

- Bracket size

- Bracket: 155mm * 95mm * 35mm; Hand lever: 315mm * φ 30mm

Introduction

DB25-204M series muscle strength Tester is a digital push-pull force meter. It has the advantages of high precision, easy operation and easy to carry. Combined with various test benches and fixtures, it can be used to form a testing machine for different purposes. There are many specifications of the muscle strength Tester for users to choose, and users can choose the corresponding specifications of the instrument according to the force value of the product to be tested. The scientific use test range is 10%~100% of the full scale, and the metrology department recommends not to use the part below 1% of the full scale. At the same time, after the instrument and the object under test are in place, before starting the test, press the ZERO button to clear to eliminate the weight of the fixture. Muscle strength Tester is a small, simple, multi-functional, high-precision thrust, testing instrument ergonomic analysis is simple and accurate, is a good choice for workplace design, strength evaluation and ergonomic research.

Features

High precision and high resolution.

Digital display, no parallax.

N (Newton), kg (kg), 1b (pound), g (gram) four units of measurement are availableMutual conversion.

Peak hold function. Hold the peak display until it is manually cleared.

Green and environmentally friendly, 10 minutes without operation automatic shutdown; It can also be turned off manuallyMachine.

Can be powered by alkaline batteries; It can also be connected to a 5V DC power supply.

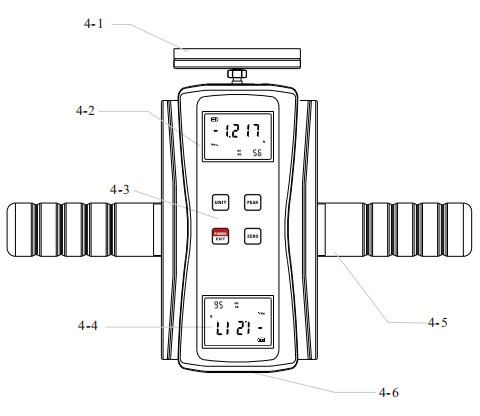

Product structure diagram

4-1 Sensing Screws:The screw is the structural part of the force sensing of the entire instrument, and its function is to conduct muscle strengthTest. It can connect the square indenter of the rubber pad, the rectangular indenter of the rubber pad, and the arc pressure of the rubber padHead.

4-2 Display A:It is used to display measurement readings, units of measurement, prompts during operation, etc。

4-3 Operation Button Area:All the operation buttons are distributed, and the key operation of the entire instrument is completed here。

4-4 Display B:It is used to display measurement readings, units of measurement, prompts during operation, etc. its mainlyThe effect is to facilitate the reading in multiple directions.

4-5 Fixing Handlebar:It is a fixed structural part of the instrument.

4-6 Power Connector:It can be connected to a 5V DC power supply to achieve DC power supply.

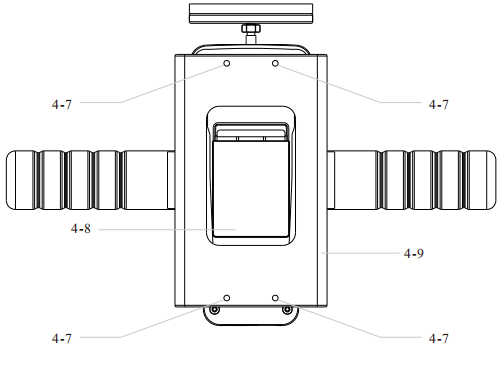

4-7 Fixing Screw Hole:It is also a fixed structural part of the instrument, which can be used with other components to fix the instrument。

4-8 Rear Battery Compartment:Where the battery is installed, the battery is powered.

4-9 Brackets:Stabilize the instrument。

DB25-204M

DB25-204M