TQC SP1691 Single Cross Hatch Cutter Set CC2000 Series Cross Hatch Cutter

TQC sheen SP1691 Single Cross Hatch CutterSPEC

TQC sheen SP1691 Single Cross Hatch CutterDetails

TQC sheen SP1691 Single Cross Hatch CutterPacking list

- SKU

- NB004751

- Number of teeth

- 6 teeth

- Tooth spacing

- 2mm

- Instrument material

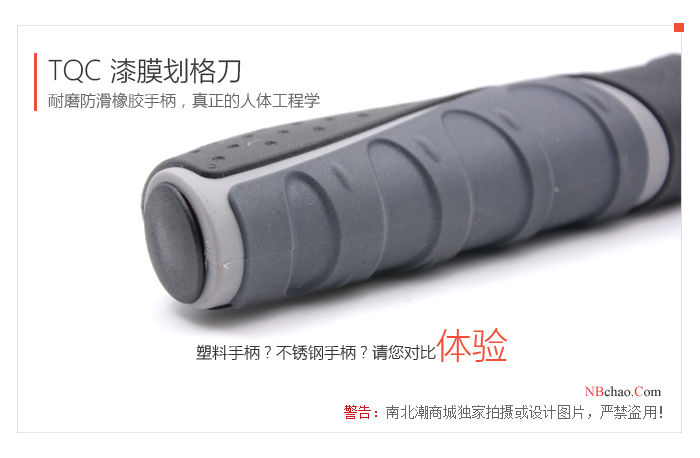

- Vacuum hardened stainless steel, aluminum, rubber

- Application standard

- ISO2409、ASTM D3359

- Applicable film thickness environment

- 0~60µm (soft substrate), 61~ 120µm (solid substrate), 50~125μm (solid substrate)

- Appearance size

- 32*173*42mm

- Instrument Weight

- 238g

Introduction

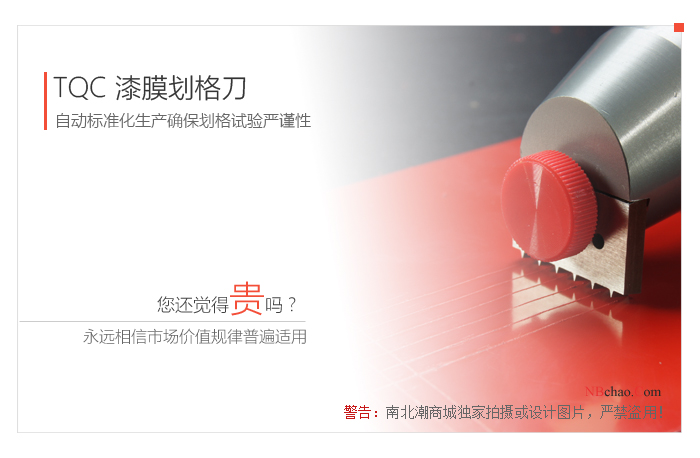

The TQC CC2000 single cross-hatch adhesion Tester series includes five models: SP1690, SP1691, SP1692, SP1699, and SP1700. It has a holder design that can automatically adjust the blade and a rotating handle to balance the pressure on the blade without requiring additional The tool can be changed into a cutter. TQC's single scratcher is imported from the Netherlands and has tools that can be used to detect different coating film thicknesses and substrate adhesion according to standards. Each set of paint film adhesion Tester is composed of a lightweight and comfortable handle and a tough knife, and the specifications are easy to carry. Also includes brushes, small magnifying glass, and tape.

Related supporting products [need to be purchased separately]

SP9700 illuminated magnifying glass 2.5x

SP1710 nylon brush for adhesion testing

SP3010 tape, three rolls, adhesion 4.3 N/cm

SP3020 tape, one roll, adhesion 7.6 N/cm

SP3007 tape, one roll, adhesion 4.3 N/cm

Principle of cross-hatch experiment

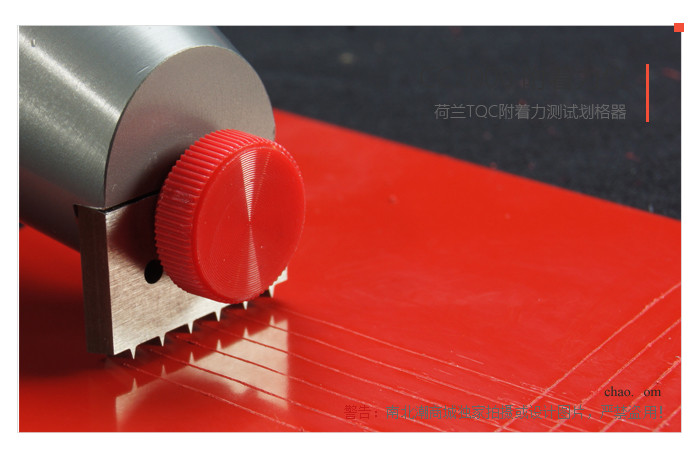

The TQC brand paint adhesion Tester uses the cross-hatch method - the internationally recognized most simple and effective test method for testing adhesion. The adhesion of a sample can be quickly measured by simply making a series of different cuts on the dry coated paint on the substrate.

Simply put, the cross-hatch method is to use a row of 6/11 blades between the two outer conductors of the adhesion Tester to cut out two perpendicularly intersecting parallel lines to obtain 25 or 100 squares, and then in the area where the parallel lines intersect Use followed by a short treatment with a stiff brush or tape treatment on hard substrates to assess adhesion.

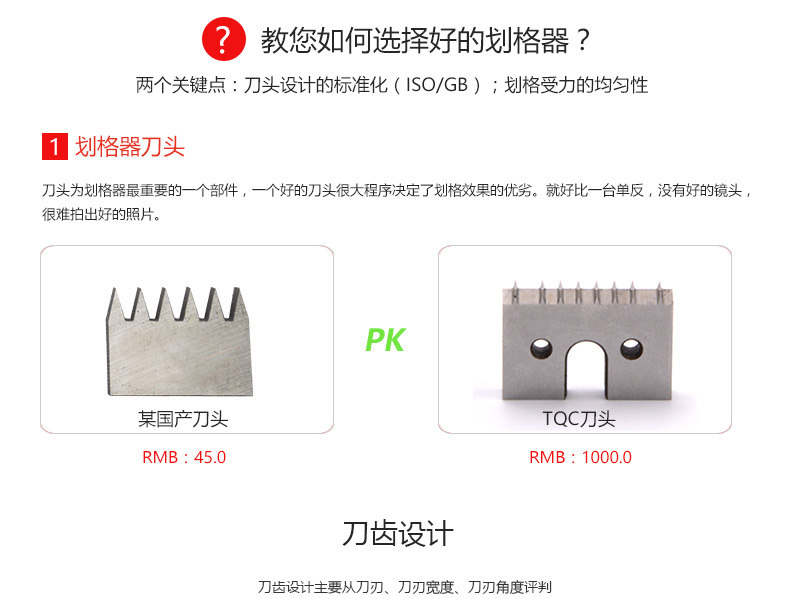

Product details

Comparison table of full range of adhesion Tester models

| TQC | Teeth | CC1000 | CC2000 | CC3000 | Suitable for thick film environment |

| cross-hatch adhesion Tester | - | Self-adjusting blade holder, round cutter with 8 cuts | Self-adjusting blade holder allows for easy changing of the cutter, with a rotating handle and no additional tools required | The blade holder maintains a fixed distance between the paint surface and the two auxiliary wheels, and the cutting depth can be accurately adjusted to ensure repeatability. | - |

| ISO2409/ASTM D3359 | 1 | VF1839 | SP1690 | SP1680 | ISO2409: 0~60μm (solid substrate) ; ASTM D3359: 0~50μm (solid substrate) |

| ISO2409 / ASTM D3359 | 2 | VF1842 | SP1691 | SP1681 | ISO2409: 0~60μm (soft substrate), 61-120μm (firm substrate ) ; ASTM D3359: 50~125 μm (solid substrate) |

| ISO/DIN2409 | 3 | VF1844 | SP1692 | SP1682 | 121-250μm (solid substrate ) |

| ASTM 3359ï¼2009 | 1 | VF1846 | SP1699 | SP1683 | 0~50μm (solid substrate ) |

| ASTM 3359 is less than 2009 | 1.5 | VF1847 | SP1700 | SP1684 | 50~125μm (solid substrate ) |

Take you into the Dutch TQC

- 1JJF 2163-2024《Calibration Specification for Paint Film Scribers》

- 2SJ 20910A-2018《General specification for powder spraying coating》

- 3GB/T 9286-2021《Paints and varnishes—Cross-cut test》

- 4GB/T 23997-2009《Solvent-thinned polyurethane wood coatings for indoor decorating and refurbishing》

- 5HG/T 20720-2020《Construction and acceptance specification of waterborne anti-corrosion coatings for steel structures in industrial buildings》

- 6HG/T 5776-2020《Water-based coatings for surface of rubber sealing products》

- 7HG/T 5187-2017《Automobile axle spring anticorrosive primer》

- 8HG/T 5183-2017《Water-based ultraviolet curing coatings for woodenware》

- 9HG/T 5299-2018《Optical polyethylene terephthalate(PET) transparent hardening film for indium tin oxide(ITO)》

- 10HG/T 3829-2006《Floor coatings》

SP1691

SP1691