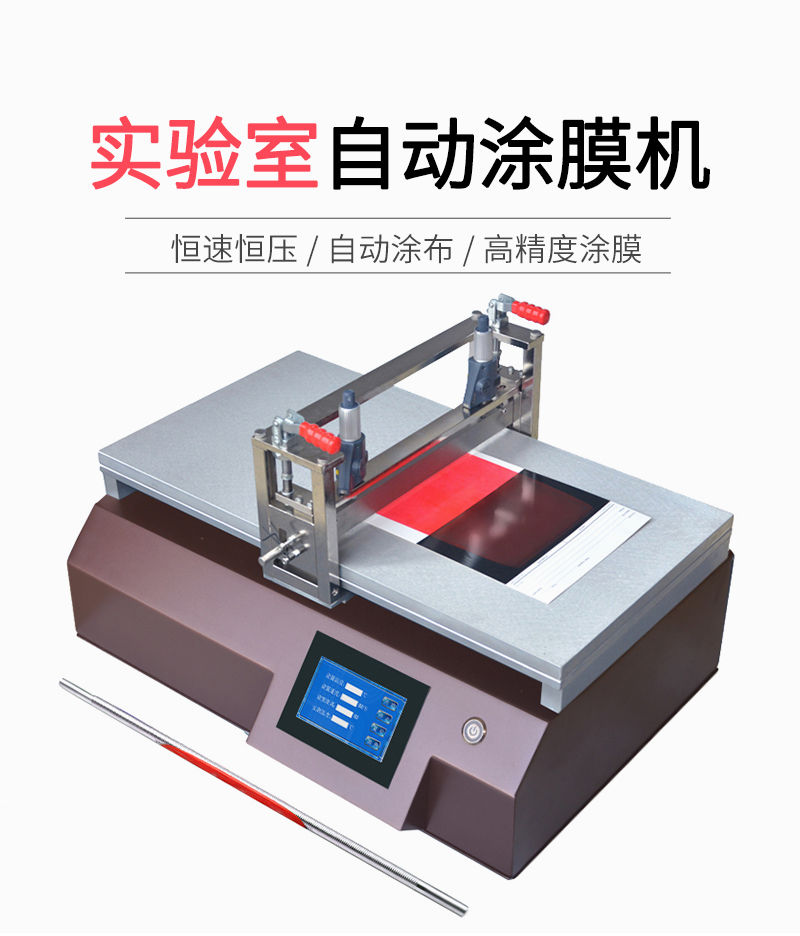

CHINA Perovskite Experimental Film Applicator TBJ-X3-ABO with imported bar with air knife + air knife bracket

zy TBJ-X3-ABO6 Automatic Film ApplicatorSPEC

zy TBJ-X3-ABO6 Automatic Film ApplicatorDetails

zy TBJ-X3-ABO6 Automatic Film ApplicatorPacking list

- SKU

- NB047510

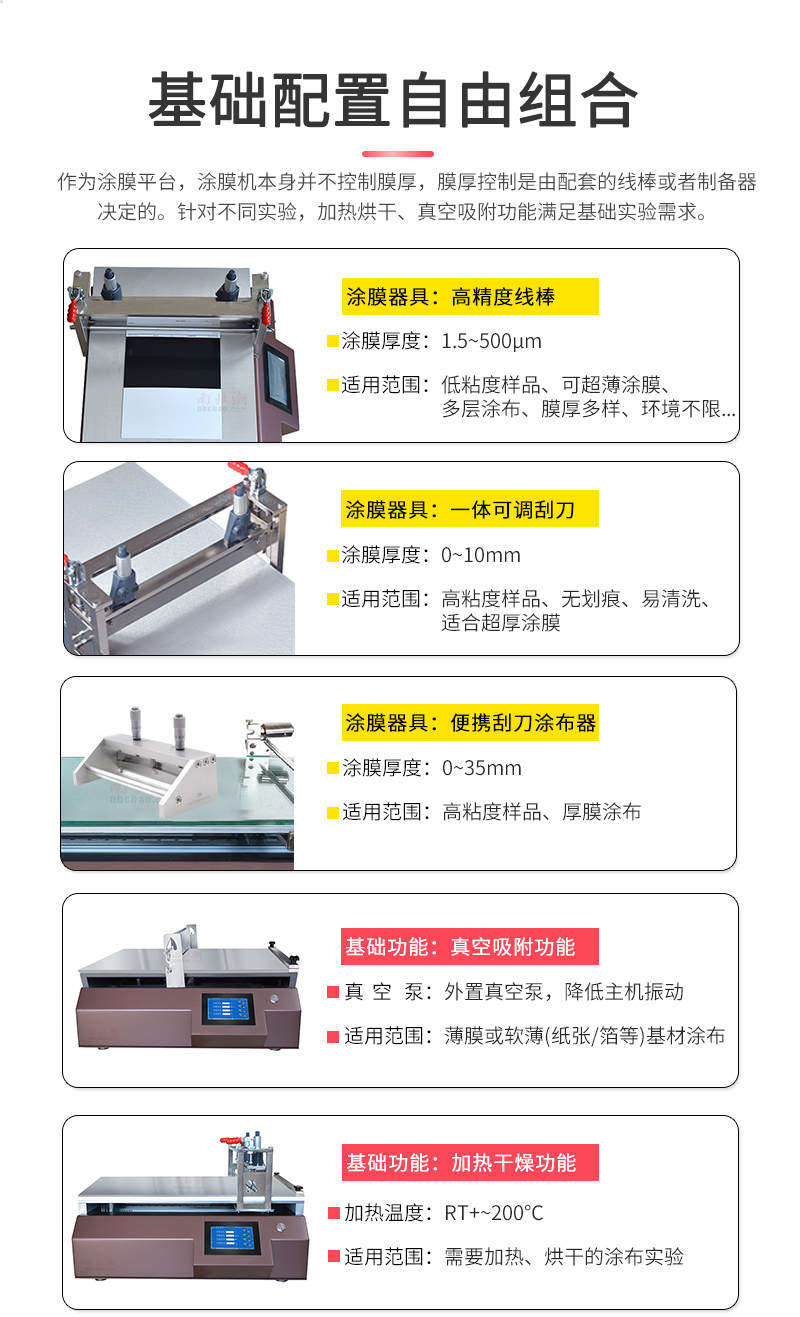

- Coating method

- Bar + adjustable drawdown blade + air knife + air knife bracket

- Drawdown blade type

- Integrated drawdown blade

- Drawdown blade Accuracy

- ±0.003mm

- Drawdown blade thickness range

- 0~10Mm drawdown blade can be lifted

- Drawdown blade material

- 304 stainless steel

- Mayer Rod Thickness Range

- 1-571.5 μm (Spreader thickness according to bar model)

- Mayer Rod Accuracy

- ±0.001mm

- Coating speed

- 5-200Mm/s (< 5mm/s can be customized)

- Coating size

- 300 * 400Mm (Miscellaneous size can be customized)

- Spreader distance control

- The number can be set arbitrarily within the range of 1-400mm

- Vacuum Area

- 300 * 400Mm (can be customized)

- vacuum aperture

- Φ1.2mm

- Vacuum hole spacing

- 20*20mm

- Vacuum pump size

- 380*180*280mm

- Substrate clamping method

- Vacuum adsorption

- Control mode

- Touch screen control

- Host Power Supply

- 220V 50Hz

- Net Weight

- 65KG

- speed control

- Infinitely variable speed

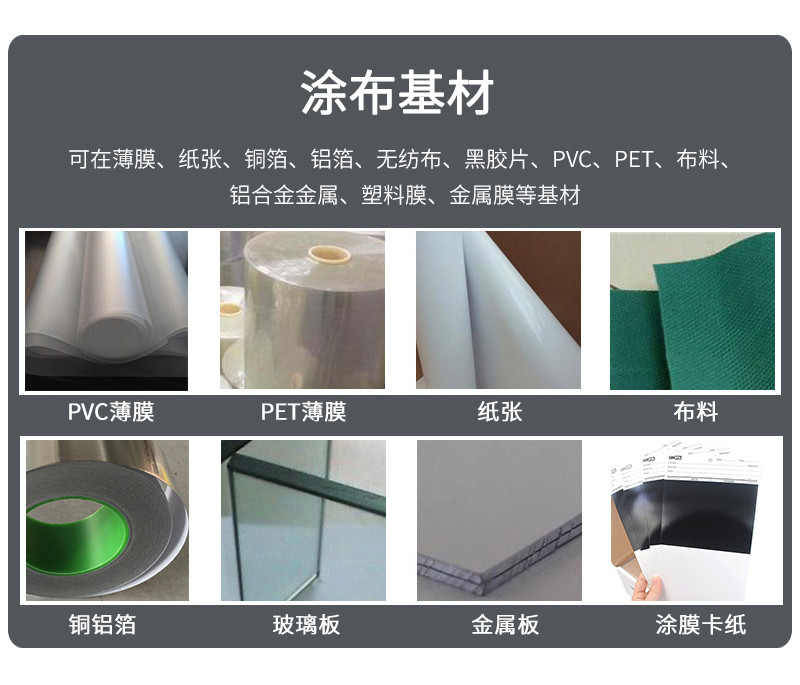

- Coating table material

- aluminum alloy

- configuration function

- Air knife + air knife bracket

- Dimension

- 630*410*520mm

- Heating Temperature range

- RT+~180℃

- Temperature Uniformity

- ±3℃

- Heating mode

- Baseplate heating

- Air knife gap

- 0.05mm

- Air knife Accuracy

- ±0.002mm

- Optional Accessories

- Leakage tank, substrate fixture, trimming horizontal height support foot device, Glass plate, silicone pad and Weight (for applications with uneven thickness of Spreader substrate), application width control baffle

- customizable function

- Automatic lame plating device, remote control, upper infrared heating, double extrusion Spreader

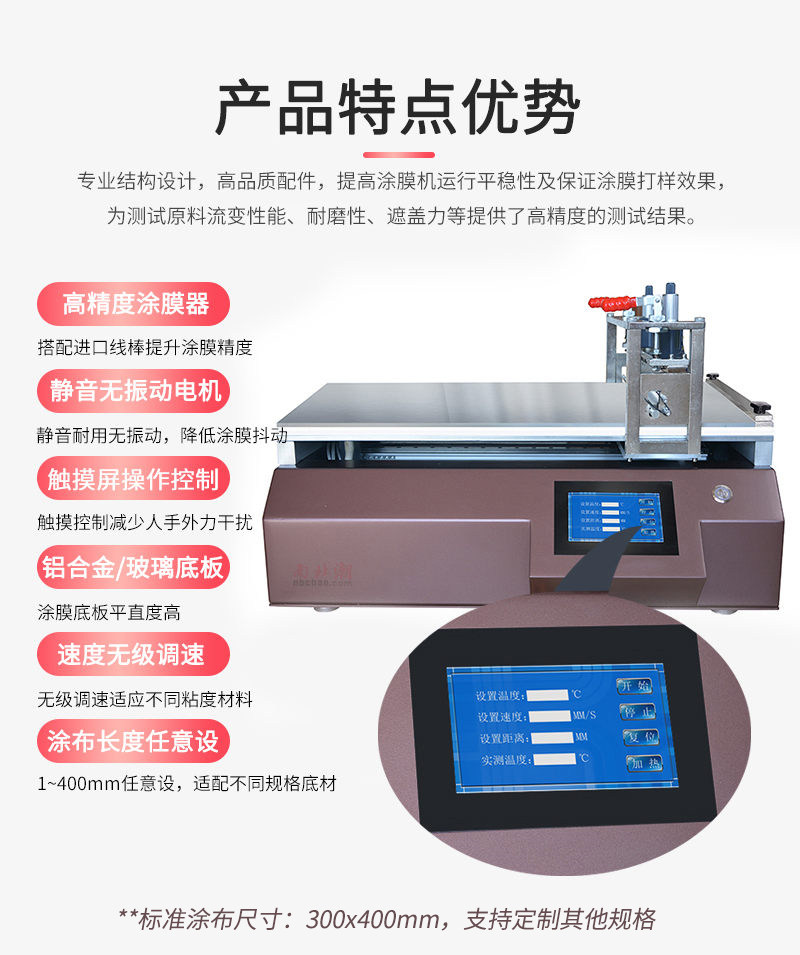

Overview

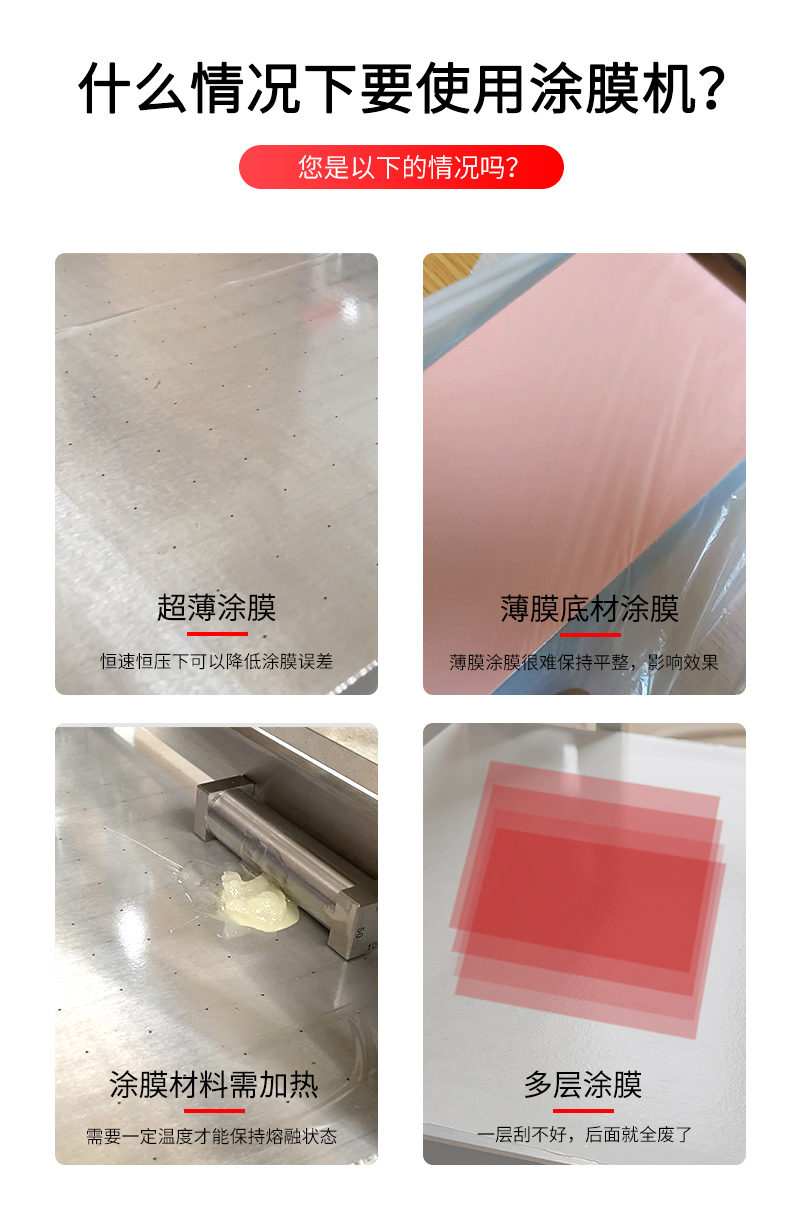

The perovskite special coating machine is equipped with an imported high-precision wire rod coater, with heating and vacuum adsorption functions, equipped with air knife and air knife support, using nitrogen as the air source to accelerate the drying of perovskite solution, realizing 360-degree angle adjustment of air knife, and the thinnest dry film can reach the nanometer level.

Due to the main factors affecting the coating film and the pressure applied to the coater, the coating applied by the manual coating is often inconsistent, especially the difference between different people is greater, which brings difficulties to the comparison of test results between samples. The automatic Film Applicator is carefully designed to allow the operator to easily apply a precise wet film on different substrates, which greatly improves the reproducibility of the coating film.

TBJ-X3-ABO6

TBJ-X3-ABO6