DUBAN UTTM7-DB25-207FM-5N Universal Tensile Tester, Range +/- 4.9N

Duban UTTM7-DB25-207FM-5N Tensile TesterSPEC

Duban UTTM7-DB25-207FM-5N Tensile TesterDetails

Duban UTTM7-DB25-207FM-5N Tensile TesterPacking list

- SKU

- NB047525

- Measurement range

- ±0.5kgf、±500gf、±4.9N、±1.1Lbf

- Force Precision

- Level 0.5

- Force resolution

- 0.001kgf、1gf、0.01N、0.001Lbf

- Accuracy

- +/- 0.5% FS (range) +/- 1 digital peak

- unit

- kgf, gf, N, Lbf

- Measured value

- Peak, instantaneous value

- show

- Four large LCD, forward and reverse dual display

- shutdown mode

- 10 minutes automatic shutdown or manual shutdown

- Backlight

- Blue Backlight

- Allowable load

- 150% F.s (buzzer alarm when it exceeds 110% F.s)

- Power Supply

- 2 AA batteries or 5V DC Power Supply

- Operating temperature

- 0°C~40°C

- Operating humidity

- < 80%

- Operating Environment

- No source and corrosion medium around

- Host size

- 199mmx76mmx37 mm

Introduction

Universal Tensile Testing Machine is a small, simple, multi-functional and high-precision thrust and tensile testing instrument, which is widely used in electronic appliances, building hardware, light industry textiles, auto parts, lighters and other ignition devices, fire-fighting equipment, pen-making, lock-making, fishing gear, chemical industry, power machinery, scientific research institutions and other industries of push-pull load, plugging and pulling force testing, destructive testing, etc.

Features

High precision and high resolution. Digital display, no parallax.

N (Newton), kg (kilogram), lb (pound), g (gram) four units of measurement can be selected and converted to each other.

Peak hold function. Hold the peak display until it is manually cleared.

It can be set to automatically shut down for 10 minutes without operation; It is also possible to shut down manually.

Can be powered by alkaline batteries; It can also be connected to a 5V DC power supply.

Product structure diagram

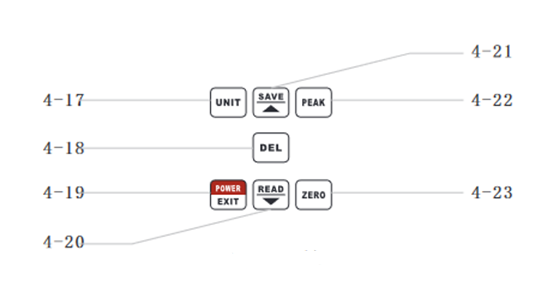

Operation buttons

4-17 UNIT: THE UNIT CONVERSION KEY, WHICH IS USED FOR UNIT CONVERSION OPERATIONS.

4-18 Delete Key (DEL): The key to delete the stored data.

4-19 POWER/EXIT: The power on/off button is also the return button in data browsing mode, or the operation button to bring up the auto-shutdown setting.

4-20 READ/T: The operation button to enter the data browsing mode, which is also the transfer button for data transfer to the computer, the down button when browsing the saved data, and the conversion button when setting the shutdown time.

4-21 SAVE/▲: The operation button when saving the measurement reading, the up button when browsing the saved data, and the switch key when setting the shutdown time.

4-22 PEAK: Switch between peak hold mode and real-time measurement mode.

4-23 Zero Calibration Button (ZERO): The operation button for instrument zero calibration.

Selectable measuring ranges

2N、5N、10N、20N、50N、100N、200N、500N、1KN

Scope of use

Terminals, wires,Rope, plastic, film, rubber,Fabrics, fishing lines, masks, etc

- 1Hypertherm HDD, HDE, HDT series Tensile machine operating instructions

- 2Retrofit of Hydraulic System of 500kN Hydraulic Tensile machine

- 3Tensile machine problem analysis and solutions

- 4What factors affect the test accuracy of Tensile Testing Machine?

- 5Hypertherm HLX-J and HLX-S Tensile machine

- 6How much do you know about the maintenance and safety of Tensile machines?

- 7How to choose a suitable Tensile machine?

- 8Tensile machine test specimen 60/hour

- 9Measurement of winding wire elongation

- 10Introduction of non-metallic Tensile machine detection method

江挺 - 《科技创新与应用 》

- 1FZ/T 75004-2014《Coated fabrics.Determination of elongation and tensile permanent deformation》

- 2HG/T 4372-2012《Composite pipes and fittings for chemical industry》

- 3HG/T 6102-2022《Pressure sensitive adhesive tapes of BOPP for general purpose》

- 4HB 7625-1998《Tensile test method for carbon fiber composite laminates in hot and humid environment》

- 5NF 《Metallic and other inorganic coatings - Method for quantitative measurement of adhesion by tensile test》

- 6 2877-2022《Biaxially oriented polypropylene(BOPP) film for heat sealing》

- 7QB/T 5710-2022《No-primer biaxially-oriented polypropylene thermal base film》

- 8GB/T 26708-2011《Laser holographic anti-counterfeiting biaxially oriented polypropylene film》

- 9GB/T 17637-1998《Geotextiles and geotextile-related products--Determination of the tensile creep and creep rupture behaviour》

- 10GB/T 1040.4-2006《Plastics - Determination of tensile properties - Part 4: Test conditions for isotropic and orthotropic fibre-reinforced plastic composites》

UTTM7-DB25-207FM-5N

UTTM7-DB25-207FM-5N