TIANDIXINGHUO TCY-30 Masonry mortar ejector Measurement range 20~80%

SETianDiXingHuo TCY-30 Masonry mortar ejectorSPEC

TianDiXingHuo TCY-30 Masonry mortar ejectorDetails

TianDiXingHuo TCY-30 Masonry mortar ejectorPacking list

- SKU

- NB048038

- rated thrust

- 30Kn

- rated stroke

- 80mm

- Measurement range

- 20-80%

- Indication relative error

- ±2%

- resolution

- 0.001KN

Uses and characteristics

TCY-30 push-out instrument is used to estimate the strength of masonry mortar in the wall of 240mm thick sintered ordinary bricks, sintered porous bricks, autoclaved lime sand bricks or autoclaved fly ash bricks, and the strength of the measured mortar should be 1MPa-10MPa. During the inspection, the ejector should be placed in the hole in the wall. The instrument is a small hydraulic device, through the piston rising to push the cover plate to produce force on the block to detect the strength of the masonry, the test results are intuitive, and the detection part is partially damaged.

(1). The instrument has novel structure, small size, light weight and easy operation.

(2). The use of manual pump loading cylinder, simple and convenient operation, strong interchangeability.

(3). Digital display pressure gauge, can directly read out the shear force.

Structural characteristics and working principle

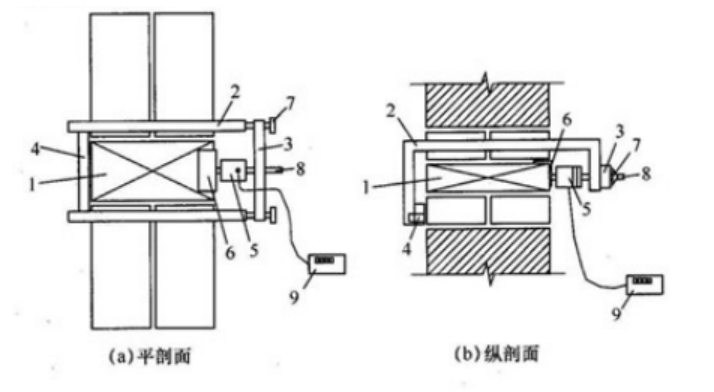

1 - was pushed out of the Ding turn; 2-a bracket; 3-front beam; 4-rear beam; 5-hydraulic cylinder; 6-a backing plate; 7-Leveling screw 9-Push out the force peak Tester

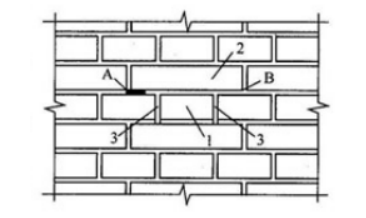

1-tested Ding brick; 2 - two bricks that were taken out; 3- Hollowed out vertical seams

As shown in the figure above, dig out the measured brick, adjust the instrument, convert the instrument to the peak state, press the manual pump pressure handle, the hydraulic oil communicates with the digital pressure gauge through the oil pipe, and the other way enters the push-out instrument to push the piston up, and the piston pushes the cover plate to exert thrust on the block. With the increase of the thrust of the block, the block shear moves, the oil pressure decreases rapidly back to zero, the digital display table records the maximum force value, and the shear strength of the masonry can be obtained by calculation. Release the relief valve and return the piston under the action of spring force.

TCY-30

TCY-30