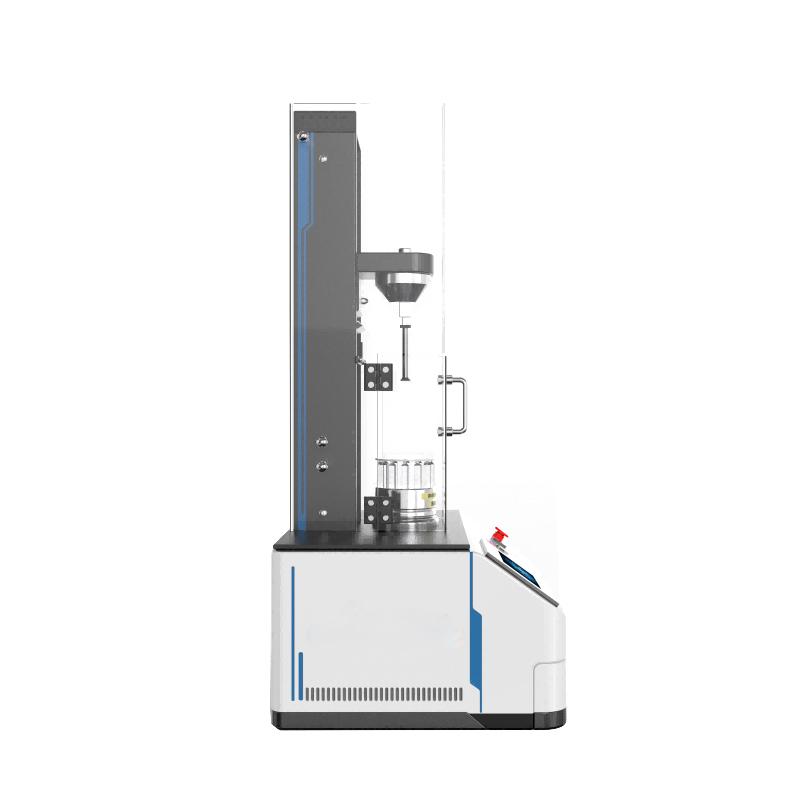

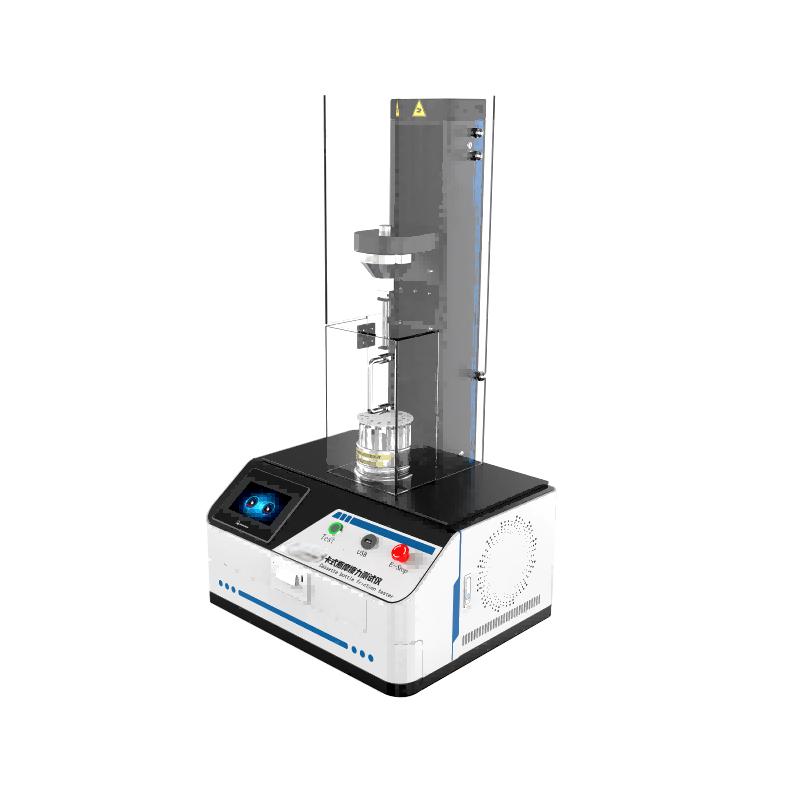

HUITAO HT-Z321 Automatic cassette bottle friction Tester, bottle friction test

SEhuitao HT-Z321 Automatic cassette bottle friction TesterSPEC

huitao HT-Z321 Automatic cassette bottle friction TesterDetails

huitao HT-Z321 Automatic cassette bottle friction TesterPacking list

- SKU

- NB048283

- Control system

- PLC + Windows system

- Operating interface

- Color 12 inch embedded industrial computer

- Force range

- 0-50N

- Accuracy

- 0.05%

- Limited itinerary

- 450mm

- Workstation

- 12 stations, automatic swirl/spin test, accurate positioning

- Station material

- Transparent material production

- Wireless remote connection printer

- Test speed

- 0-500mm/min, the speed can be set arbitrarily, continuously variable speed function, set on the touch screen

- test fixture

- 12 stations, all marked with numbers 1-12, and designed with liquid Drainage function

Description

The automatic cartridge friction Tester is a device used to test the friction of bottles. This type of equipment is often used to measure the friction of bottles (e.g. pharmaceutical bottles, cosmetic bottles, etc.) during the production process or in product packaging to ensure that the bottles produced meet the relevant standards.

This type of Tester usually tests and records the behavior of the bottle when rubbed in an automated way. Through these tests, producers can understand the friction problems that may arise in the production process of the bottles, so that adjustments can be made during the production process to ensure product quality and production efficiency.

Fully automatic cartridge friction Testers typically combine sensors, data acquisition systems, and automated control systems to provide accurate test results, and can perform data analysis and report generation as needed. This equipment has a wide range of applications in a variety of industries and is especially useful in production environments where high accuracy and reliability are required.

Software parameter requirements

Operation interface mode: Chinese and English interface;

There are 3 types of permissions to enter the interface: Operator, Manager, Administrator

User Configuration: Chinese computer systems must handle at least three different user configurations

Operator's permissions: Perform predefined tests, report test results

Authority of the Manager: Same as the Operator, Creation and Change of Test Methods-

Administrator permissions: Configure system parameters

Assign permissions - create, disable, or adjust users and passwords

Exclude test subjects

Curves: The system records and displays the force/displacement curves. According to this curve, the values of force and displacement must be displayed on the screen and the results can be printed

The test device must initiate auto-zero before each set of tests

The test starting position is height-adjustable, designed to be in view, and the handle is adjustable

HT-Z321

HT-Z321