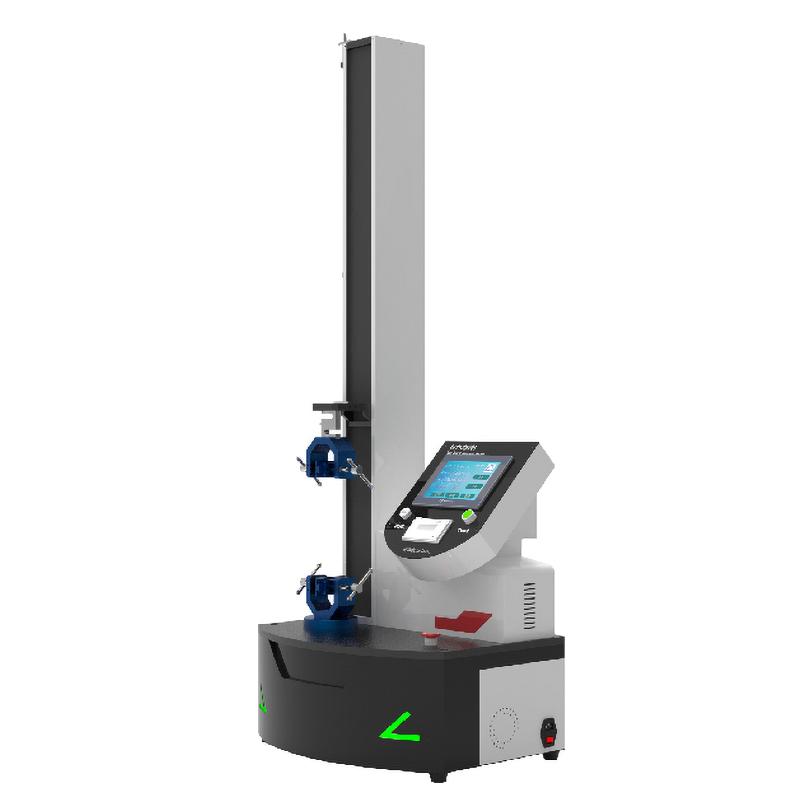

HUITAO HT-BO23 Soft Encasement Material Ink coating adhesion Tester

SEhuitao HT-BO23 Coating adhesion TesterSPEC

huitao HT-BO23 Coating adhesion TesterDetails

huitao HT-BO23 Coating adhesion TesterPacking list

- SKU

- NB048308

- Measurement range

- 0-500N, J degree 3/1000

- Test speed

- (300~450) mm/s (Z size can be arbitrarily set to 700mm/s)

- Control system

- PLC

- Operating interface

- Switch between Chinese and English;

- Sampling Frequency

- 2000Hz

- Effective width of gripper

- Optional according to needs (standard configuration)

- Blessing method

- Manual clamp

- Output various forms of print results

Scope of application

Poor adhesion of ink or coating on substrate can affect the readability of printed material, affect the functionality of the coating material, or create a source of contamination. This section provides a method for evaluating the adhesion of inks or coatings on flexible packaging materials. To address inconsistencies between laboratories, the test methods in this section can be improved by specifying and controlling the pressure and methods used by the tape (e.g., speed and angle at which the tape is removed). This section does not deal with acceptance criteria and needs to be mutually agreed upon by both the supply and demand sides of the product.

Enforce the standard

YY/T 0681.7-2011

Test procedure

Place the test sample on a flat surface, and the sample should be placed flat, without wrinkles, creases or creases;

A length of tape for the printing or layering of the test sample. For larger surfaces, several strips of tape may be easier to handle. It is easier to apply and remove the tape when the tape length is up to 30 cm;

Attach the tape to the product with a smooth and coherent action belt or in a non-productive way, and slide the finger and index finger strap to ensure that it is glued and that there are no air bubbles on the surface.

Hold the sample flat in one hand and peel off the tape 120,150 degrees in the other hand towards the back. Lift the tape and pull it back with a coherent and moderate motion, and its speed is usually 300 mm/s~450 mm/s.

Note: The time after the tape has been applied varies and may affect the results.

Check the test sample for missing printing or intermittent coating

There are no layers of tape that are transferred from the test sample. A reference standard can be established as an aided visual test to determine the extent of metastasis.

Document the results. The degree of pasting is characterized with a negotiated reference. If more than one color is printed, the reported results may vary depending on the color. This is a subjective and judgmental trial, and operator training is critical to the consistency of reporting test results.

Instrument characteristics

Highly sensitive touch interface, easier operation experience

The test process can dynamically display the curve, strength, elongation, elongation, time, etc. in real time, and can also realize the interchange function of Chinese and English interfaces, providing guarantee for dealers who do import and export trade.

Full digital control system, 32-bit single-chip microcomputer, data sampling frequency of 2000Hz

The gantry double-column frame adopts the method of high J density preload ball screw + optical shaft to ensure that the machine runs more stably and the stress and strain value is more accurate.

It can be connected to computer software to control machine operation and data processing, generate data reports, curves, etc., for archiving and viewing.

Various functions can be customized through software, and it is easy to cope with various standard updates and upgrades.

HT-BO23

HT-BO23