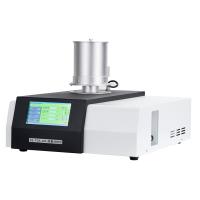

Huicheng STA-1550 Synchronous Thermal Analyzer TG/DTA/DSC Differential Thermal Analysis 1550 ℃

SEHuiCheng STA-1550 Synchronous Thermal AnalyzerSPEC

HuiCheng STA-1550 Synchronous Thermal AnalyzerDetails

HuiCheng STA-1550 Synchronous Thermal AnalyzerPacking list

- SKU

- NB048387

- Temperature Resolution

- 0.01℃

- Temperature Fluctuation

- ±0.1℃

- Heating rate

- 0.1~100℃/min

- Cooling rate

- 1~20℃/min

- Temperature control method

- Heating, thermostatic, cooling

- cool down

- 15min(1000℃…100℃)

- Balance Measurement Range

- 1mg~2g

- resolution

- 0.1μg

- DSC range

- 0~±500 mW

- DSC resolution

- 0.01 mW

- Thermostatic time

- 0~300Min (arbitrary setting)

- display mode

- Large LCD display of Chinese characters

- atmosphere

- Inert, oxidation, reducing, static, dynamic

- Atmosphere device

- Built-in gas flow meter, including two-way gas switching and flow size control

- operating software

- Intelligent software can automatically record TG Linear dispersion for data processing and print experimental reports

- Data Interface

- Standard USB interface, dedicated software (free software upgrades from time to time)

- Power Supply

- AC220V/50Hz

Synchronous thermal analysis combines thermogravimetric TG with differential thermal analysis DTA or differential scanning calorimetry DSC, and the information of TG and DTA or DSC can be obtained synchronously using the same sample in the same measurement. Thermogravimetric analysis (TG, TGA) is to observe the change of the mass of a sample with temperature or time during the process of heating, constant temperature or cooling, with the aim of studying the thermal stability and composition of the material. It is widely used in research and development, process optimization and quality control in various fields such as plastics, rubber, coatings, catalysts, inorganic materials, metal materials and composite materials. Synchronous thermal analysis combines thermogravimetric TG with differential thermal analysis DTA or differential scanning calorimetry DSC, and the information of TG and DTA or DSC can be obtained synchronously using the same sample in the same measurement.

Instrument use

Measure and study the following properties of materials:

DSC: melting, crystallization, phase change, reaction temperature and heat of reaction, heat of combustion, specific heat......

TG: thermal stability, decomposition, redox, adsorption and desorption, free water and crystalline water content, component ratio calculation, etc.

Key features:

The balance comes with internal calibration for better accuracy and repeatability;

Imported platinum-rhodium alloy sensor is adopted, which is more corrosion-resistant, oxidation-resistant, and has high sensor sensitivity.

The furnace body is heated by precious metal alloy wire winding, which reduces interference and is more resistant to high temperature.

Perfect atmosphere control system, automatic switching of software settings, data is directly recorded in the database;

The Cortex-M3 core ARM controller is used for faster computing and processing speed, and the temperature control is more accurate.

Adopt USB two-way communication to fully realize intelligent operation;

It adopts a 7-inch 24-bit full-color LCD touch screen to display the status and data of the instrument in real time;

It adopts a top-opening lid structure, which is easy to operate. It is difficult to move the furnace body to place the sample, which is easy to cause damage to the sample rod.

Automatically generate test reports and print them. The software has built-in test records, data processing, and report formats, and automatically issues experimental reports.

- 1GB/T 45939-2025《Co-extrusion encapsulant film for photovoltaic module》

- 2GB/T 19469-2004《Determination of ignition temperature of pyrotechnic composition--DTA-TG analysis》

- 3GB/T 27762-2011《Standard test method for mass scale calibration of thermogravimetric analyzers》

- 4GB/T 27761-2011《Standard test method of mass loss and residue measurement validation of thermogravimetric analyzers》

- 5GB/T 14837.1-2014《Rubber and rubber products―Determination of the composition of vulcanizates and uncured compounds by thermogravimetry―Part 1:Butadiene, ethylene-propylene copolymer and terpolymer, isobutene-isoprene, isoprene and styrene-butadiene rubbers》

- 6GB/T 33047.1-2016《Plastics—Thermogravimetry (TG) of polymers—Part 1: General principles》

- 7GB/T 34916-2017《Nanotechnologies—Multi-walled carbon nanotubes—Determination of amorphous carbon content by thermogravimetric analysis》

- 8GB/T 35930-2018《Determination of vapor pressure of chemical products—Thermogravimetry method》

- 9GB/T 14837.3-2018《Rubber and rubber products—Determination of the composition of vulcanizates and uncured compounds by thermogravimetry—Part 3:Hydrocarbon rubbers,halogenated rubbers and polysiloxane rubbers after extraction》

- 10GB/T 33047.3-2021《Plastics—Thermogravimetry (TG) of polymers—Part 3: Determination of the activation energy using the Ozawa-Friedman plot and analysis of the reaction kinetics》

STA-1550

STA-1550