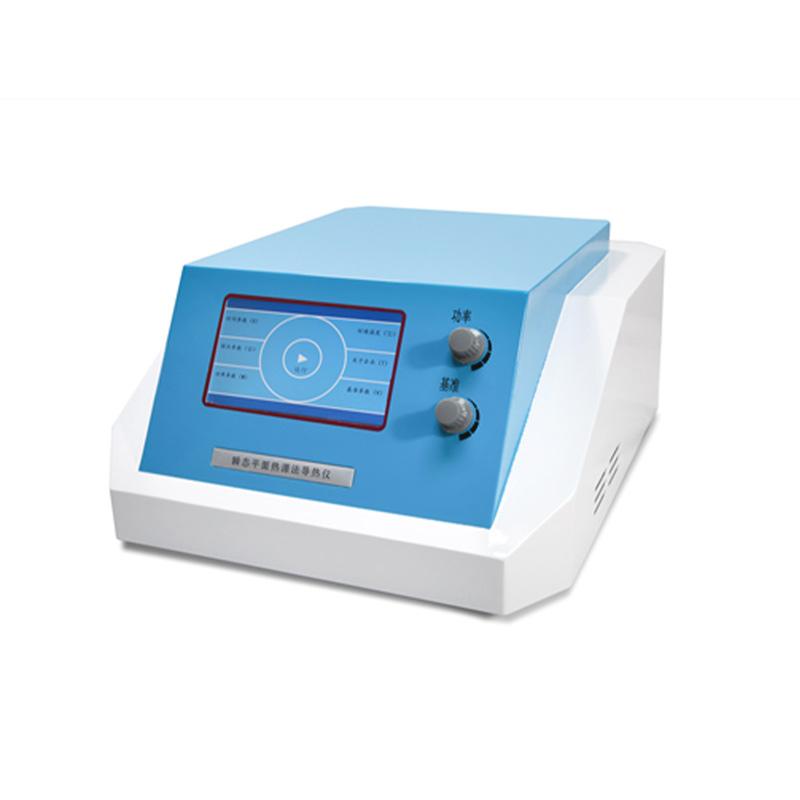

Huicheng HCDR-S thermal conductivity Tester, high-low temperature thermal resistance performance test

SEHuiCheng HCDR-S Thermal conductivity TesterSPEC

HuiCheng HCDR-S Thermal conductivity TesterDetails

HuiCheng HCDR-S Thermal conductivity TesterPacking list

- SKU

- NB048388

- test range

- 0.0001—300 W/(m*K)

- Measurement sample temperature range

- -20 ℃ - 200 ℃ (external temperature control equipment is required)

- probe diameter

- No. 1 probe 7.5mm; No. 2 probe 15mm; No. 3 probe 30mm

- Accuracy

- ±3%

- Repeatability Error

- ≤3%

- Measurement time

- 5 to 160 seconds

- Power Supply

- AC 220V

- Overall power

- ﹤500w

- Sample temperature rise

- ﹤15℃

- Test sample power P

- No. 1 probe power 0 < P < 1w; No. 2 probe power 0 < P < 14w; No. 3 probe power 0 < P < 14w

- Sample specification

- A single sample measured by the No. 1 probe (15 * 15 * 3.75mm); a single sample measured by the No. 2 probe (30 * 30 * 7.5mm); a single sample measured by the No. 3 probe (60 * 60 * 20mm)

HCDR-S is a thermal conductivity Tester developed using transient planar heat source technology (TPS), which can be used to test the thermal conductivity of various types of materials. The transient planar heat source method is a new type of method for studying heat conductivity and takes measurement technology to a whole new level. The ability to quickly and accurately measure thermal conductivity when studying materials provides great convenience for enterprise quality control, material production and laboratory research. The instrument is easy to operate, the method is simple and easy to understand, and there will be no damage to the sample being measured.

Operating Principle

Transient planar heat source technology (TPS) is a novel method for measuring thermal conductivity. The principle for determining the thermophysical properties of materials is based on the transient temperature response generated by a step-heated disc-shaped heat source in an infinite medium. A flat probe is made of a thermally resistive material, which acts as both a heat source and a temperature sensor. The thermal resistance coefficient of the alloy is a linear relationship between temperature and resistance, that is, the heat loss can be known by understanding the change of resistance, which reflects the thermal conductivity of the sample. The probe of this method is a continuous double helix structure sheet formed by etching of conductive alloy, and the outer layer is a double-layer insulating protective layer, which is very thin, which makes the probe have a certain mechanical strength and maintain electrical insulation between the probe and the sample. During the test, the probe is placed in the middle of the sample for testing. When an electric current passes through the probe, a certain temperature rise is generated, and the heat generated is simultaneously diffused to the samples on both sides of the probe, and the speed of heat diffusion depends on the thermal conductivity of the material. By recording the temperature and the response time of the probe, the thermal conductivity can be obtained directly from the mathematical model.

Test object

Metals, ceramics, alloys, ores, polymers, composite materials, paper, fabrics, foams (surface insulation materials, plates), mineral wool, cement walls, cement polystyrene boards, sandwich concrete, glass fiber reinforced plastic panel composite panels, paper honeycomb panels, colloids, liquids, powders, granular and paste solids, etc., test objects are wide.

Features

The test range is wide and the test performance is stable, which is at the forefront level among similar instruments in CHINA;

Direct measurement, the test time can be set from about 5-160s, which can quickly and accurately measure the thermal conductivity, saving a lot of time;

It is not affected by the contact thermal resistance in the same way as the static method;

No special sample preparation is required, there are no special requirements for the shape of the sample, and the bulk solid only needs to be relatively smooth on the sample surface and meet the length and width of at least twice the diameter of the probe;

Non-destructive testing of the sample means that the sample can be reused;

The probe is designed with a double helix structure, combined with the exclusive mathematical model, and the core algorithm is used to analyze and calculate the data collected on the probe.

The structure of the sample stage is ingenious, easy to operate, suitable for placing samples of different thicknesses, and at the same time simple and beautiful;

The data acquisition on the probe uses an imported data acquisition chip, which has a high resolution and can make the test results more accurate and reliable;

The control system of the host uses ARM microprocessor, which is faster than the traditional microprocessor, which improves the analysis and processing ability of the system and makes the calculation results more accurate.

The instrument can be used for the determination of thermal physical parameters such as bulk solids, paste solids, granular solids, colloids, liquids, powders, coatings, films, and thermal insulation materials;

Intelligent man-machine interface, color LCD screen display, touch screen control, convenient and concise operation;

Powerful data processing capabilities. Highly automated computer data communication and report processing system.

HCDR-S

HCDR-S