LEEB LBTQ914 surface roughness probe asperity Detector, multiparameter

SELeeb LBTQ914 Surface roughness MeterSPEC

Leeb LBTQ914 Surface roughness MeterDetails

Leeb LBTQ914 Surface roughness MeterPacking list

- SKU

- NB048450

- Measurement range

- Z-axis (vertical) 160μm X-axis (horizontal) 17.5mm

- resolution

- Z-axis (vertical) 0.01μm/+/- 20μm 0.02μm/+/- 40μm 0.04μm/+/- 80μm

- Measurement project

- Parameters Ra Rz == Ry (JIS) Rq Rt == Rmax Rp Rv R3z R3y Rz (JIS) Rs Rsk Rku Rsm Rmr Standard ISO, ANSI, DIN, JIS Graphical Supportability Linear dispersion,

- filter

- RC,PC-RC,Gauss,D-P

- Sampling length (lr)

- 0.25,0.8,2.5mm

- Evaluation length (ln)

- Ln= lr×n n=1~5

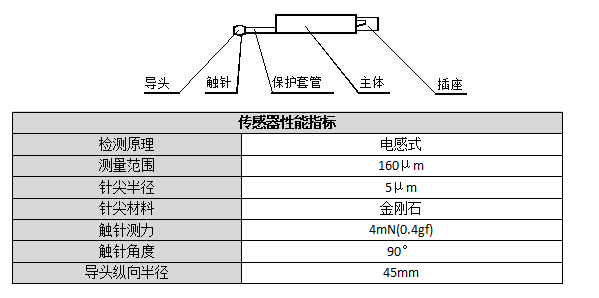

- Sensors

- Measurement principle Displacement type differential electric touch needle Natural diamond, 90 taper angle, 5μm tip radius Measurement force < 4mN Guide head Carbide, sliding direction radius 40mm

- Coasting speed

- Lr = 0.25, Vt = 0.135mm/slr = 0.8, Vt = 0.5mm/slr = 2.5, Vt = 1mm/s returns Vt = 1mm/s

- error of indication

- Not more than +/- 10%

- Indication variability

- Not more than 6%

- Power Supply

- Built-in lithium-ion rechargeable battery, charged with DC5V, 800mA charger

- Dimension

- 141×55×40mm

- Weight

- About 400g

- Operating Environment

- Temperature: - 20 ℃~ 40 ℃; Humidity: < 90% RH

- Storage and transportation environment

- Temperature: - 40 ℃~ 60 ℃; Humidity: < 90% RH

- Ra Rg

- 0.005μm~16μm

- RE; R3Z; Ry; Rt;RP;Rm

- 0.02μm~160μm

- SK

- 0~100%

- S; Sm

- 1mm

- tp

- 0~100%

Principle

When measuring the surface roughness of the workpiece, the instrument first puts the sensor on the surface of the workpiece to be measured, and then starts the instrument to measure, and the precision driving mechanism inside the instrument drives the sensor to slide along the measured surface at the same velocity, and the sensor feels the roughness of the measured surface through the built-in sharp stylus, and the roughness of the measured surface of the workpiece will cause the displacement of the stylus, and the displacement changes the inductance of the sensor inductance coil. Thus, an analog signal proportional to the measured surface roughness is generated at the output end of the phase-sensitive Detector, and the signal enters the data acquisition system after amplification and level conversion, and the DSP chip digitally filters and calculates the parameters of the collected data, and the measurement results are given on the display, can also be output on the printer, and can also communicate with the PC.

overview

Portable roughness Tester is a portable stylus surface roughness shape measuring instrument, which is suitable for the detection of workshop verification stations, laboratories, measurement rooms and other environments. The measurement parameters conform to international standards and are compatible with the standards of some industrially developed countries such as United States, Germany, Japan, United Kingdom, etc. The measurement results can be displayed digitally and graphically on the LCD display or output to a printer.

Features

Mechatronics design, small size, light weight, easy to use

DSP chip is used for control and data processing, which is fast and has low power consumption

Large range, multi-parameter Ra, Rz, Rq, Rt, Rp, Rv, R3z, R3y, RzJIS, Rsk, Rsm, Rku, Rs, RPc, Rk, Rpk, Rvk, Ry, Mr1, Mr2, Rmax

128×64 OLED dot matrix display, digital/graphic display; Highlight without Viewing Angle

The display is informative and intuitive, and all parameters and graphs can be displayed

Compatible with ISO, DIN, ANSI, JIS national standards

Built-in lithium-ion rechargeable battery and charging control circuit, high capacity, no memory effect

There is a remaining power indicator icon to prompt the user to charge in time

An indication of the charging process can be displayed, so that the operator can know the charging level at any time

More than 20 hours of continuous work

Ultra-large capacity data storage, which can store 100 sets of raw data and waveforms

Real-time clock setting and display for easy data recording and storage

It has power-saving functions such as automatic sleep and automatic shutdown

Reliable anti-motor run-off circuit and software design

Display measurement information, menu prompt information, error information, power on and off and other prompt information;

The all-metal housing design is rugged, compact, portable and reliable.

Connects to computers and printers;

All parameters can be printed or any parameters set by the user can be printed.

Curved surface sensors, small hole sensors, measuring platforms, sensor housings, and extensions are optional

Applicable Materials

It is suitable for processing industry, manufacturing, testing, commodity inspection and other departments, mainly suitable for on-site inspection of large workpieces and production lines, as well as out-of-office verification of testing, measurement, commodity inspection and other departments.

sensor

- 1What are the main manifestations of the influence of surface roughness on parts?

- 2What data is the surface roughness mainly evaluated by?

- 3Roughness and Surface Roughness

- 4High-precision roughness instrument measures the surface roughness of plastic materials Case sharing [Video demonstration]

- 5Evaluation of steel surface roughness

- 6Two Methods of Measuring Surface Roughness

- 7Which industries need to use surface roughness meters?

- 8Surface roughness measurement

- 9The relationship between abrasive and surface roughness

- 10What are the application fields of surface roughness meter?

LBTQ914

LBTQ914