BOSEAN GTQ-DX401 Gas Detector gas, oxygen, carbon monoxide hydrogen sulfide

Bosean GTQ-DX401 Gas DetectorSPEC

Bosean GTQ-DX401 Gas DetectorDetails

Bosean GTQ-DX401 Gas DetectorPacking list

- SKU

- NB048466

- Detection method

- diffusion

- Detect gas

- Combustible gas, oxygen, carbon monoxide, hydrogen sulfide

- Range

- Combustible gas: 0-100% LEL, oxygen: 0-30% VOL, carbon monoxide: 0-1000PPM, hydrogen sulfide: 0-100PPM

- resolution

- Combustible gas: 1% LEL, oxygen: 0.1% VOL, carbon monoxide: 1PPM, hydrogen sulfide: 1PPM

- Response time

- ≤ 60 seconds (T90)

- Repeatability

- ≤±2%

- Alarm mode

- Acoustic, light alarm, status indication, relay Output signal

- signal output

- Rs485 adopts standard MODBUS RTU protocol/relay switch

- Operating humidity

- ≤ 95% RH, no condensation

- Operating temperature

- -40℃~70℃

- Detect gas pressure

- 86kPa ~106kPa

- Relay load

- Two sets of relay output, touchpoint Capacity: 30VDC 2A/125VAC 1A

- Installation method

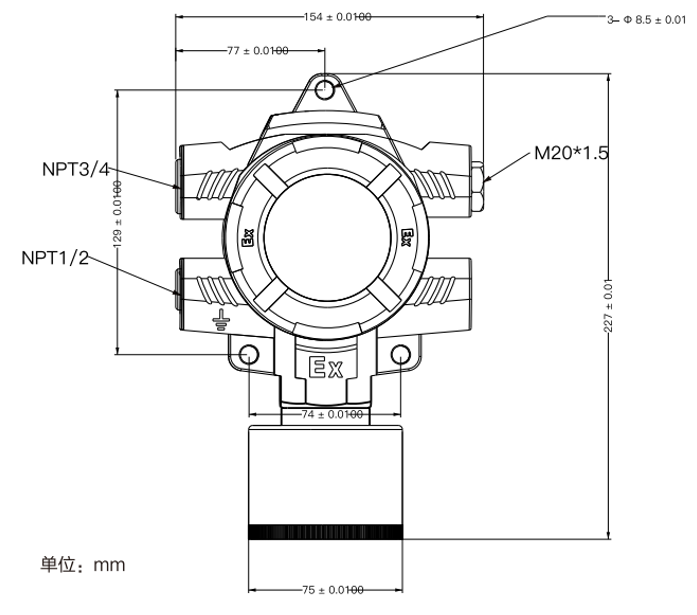

- Wall Mount, Pipeline (Thread Size: NPT)

- terminal

- M20x1.5、G1/2

- Connection Cable

- 2X0.75mm Shielding line

- shell material

- Die-casting aluminum, explosion-proof

- Dimension

- 227 * 154 * 106Mm (L x W x D)

- Weight

- About 1.8kg

- Explosion-proof sign

- Ex db IIC T6 Gb/Ex tb IIIC T80℃ Db

- Explosion-proof level

- IP66

GTQ-DX401 multi-Gas Detector (hereinafter referred to as the Detector) is an intelligent Detector designed with advanced integrated circuit technology and standard intelligent technology. The Detector adopts natural diffusion mode for gas sampling, and the sensitive element adopts high-quality gas sensor module for gas detection, which has good sensitivity and excellent repeatability, easy to use and maintain, and greatly meets the requirements of high reliability of equipment for industrial site safety detection. It can be widely used in petroleum, chemical industry, environmental protection, smelting, refining, biochemical medicine, agriculture, scientific research, universities and other industries and fields.

The design, manufacture and verification of this product comply with the following national standards:

GB 12358-2006

GB/T 3836.1-2021 "Explosive atmospheres – Part 1: General requirements for equipment"

GB/T 3836.2-2021 "Explosive atmospheres – Part 2: Equipment protected by flameproof enclosure "d"

GB/T 3836.31-2021 "Explosive atmospheres – Part 31: Equipment protected by dust-proof ignition enclosure "t"

Features

1. User-friendly GUI operation interface;

2. Color LCD screen display;

3. Advanced micropower consumption technology sensor is adopted;

4. It has the function of LCD on-site display of gas concentration, so that the on-site staff can understand the situation in time;

5. The indicator light indicates the working status, normal, low alarm, high alarm, fault;

6. The Detector shell has been inspected by the explosion-proof product inspection unit designated by the state, and has obtained the explosion-proof certificate.

Product features

1. Ultra-low power 32-bit microprocessor and 24-bit ADC data acquisition chip using semiconductor nano process;

2. Detect four gases at the same time: combustible gas, oxygen, carbon monoxide and hydrogen sulfide (can also be freely customized according to needs);

3. PPM, %VOL, mg/m, μmol/mol, units can be switched;

4. Multi-parameter LCD display with backlight large screen on site, intuitively displaying gas concentration, type, unit, working status, etc.;

5. There is no need for on-site calibration to replace the sensor, and the key parameters of the sensor are automatically identified;

6. Display in Chinese and English;

7. The sensor has up to 5 levels of target point calibration function to ensure the accuracy and linearity of the measurement;

8. Two-level alarm setting, two groups of relay passive signal output;

9. Standard RS485 signal: standard MODBUS RTU protocol, transmission distance<1km;

10. It has the functions of over-Voltage protection, lightning protection, short-circuit protection, reverse connection protection, anti-static interference, anti-magnetic field interference, etc., and has the function of automatic recovery to prevent the Detector from being damaged by any external reasons, man-made reasons, natural disasters, etc.;

Exterior structure

- 1GB 3836.16-2024《Explosive atmospheres—Part 16: Specification of electrical installations inspection and maintenance》

- 2GB/T 3836.18-2024《Explosive atmospheres—Part 18: Intrinsically safe electrical systems》

- 3GB 12358-2006《Gas monitors and alarms for workplace General technical requirements》

- 4GB 3836.4-2010《Explosive atmospheres- Part 4:Equipment protection by intrinsic safety“i”》

- 5GB 3836.4-2010《Electrical apparatus for explosive gas atmospheres- Part 4 :lntrinsic safety“i”》

- 6GB 3836.1-2010《Explosive atmospheres—Part 1:Equipment—General requirements》

GTQ-DX401

GTQ-DX401