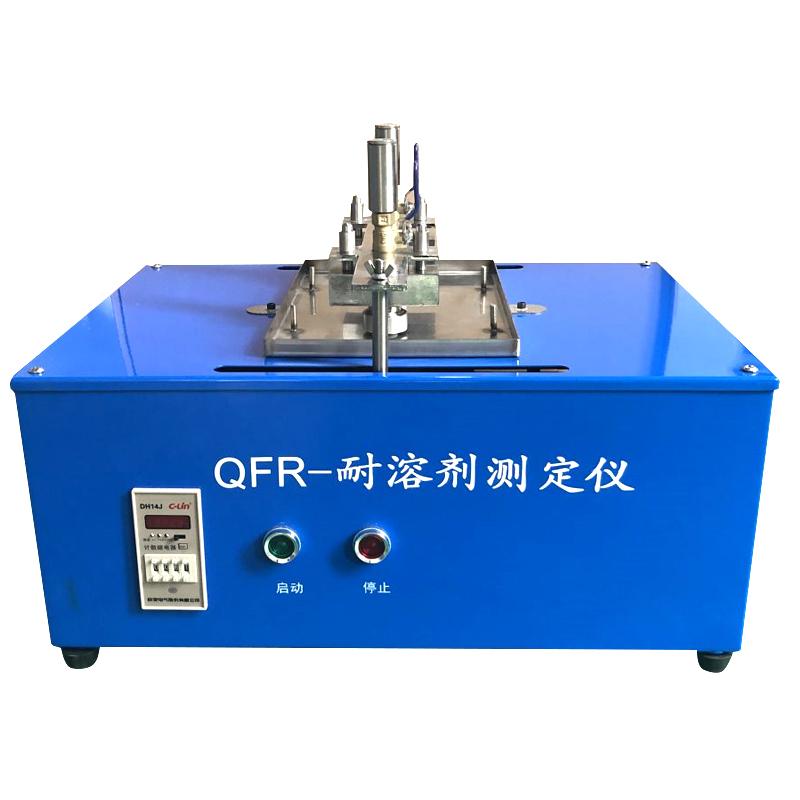

QFR coating solvent resistance Tester, aluminum-plastic composite plate coating Solvent Rub Resistance Tester

HuiNuo QFR Resistance to solvent TesterSPEC

HuiNuo QFR Resistance to solvent TesterDetails

HuiNuo QFR Resistance to solvent TesterPacking list

- SKU

- NB048511

- erasure stroke

- 100mm

- Erasure Frequency

- 100cpm

- friction load

- 1000±100g

- Grinding head area

- 2cm²

- Set Count range

- 0-9999

- Power Supply

- AC 220V 50HZ 8A

Uses and characteristics

The determination of solvent resistance of QFR type coating is based on GB/T17748-1999 standardIt is designed and manufactured in accordance with the requirements of the solvent resistance determination of coatings. mainIt is suitable for determining the solvent resistance of aluminum-plastic composite panel coatings, and can also be used for determinationSolvent resistance of other similar substrate coatings.

The instrument has reasonable structure, reliable performance, simple operation and automaticCharacteristics of counting

Operating Principle

Use a flexible head to wipe the head with four layers of medical gauze, and absorb the solvent to a certain amountThe force and frequency of scrubbing back and forth in the same place on the coated surface to the specified number of times. eyeMeasure whether the inner layer is exposed at the washing area to determine the solvent resistance of the coating

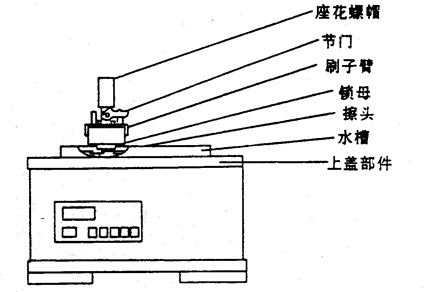

Instrument structure

The instrument consists of 3 main parts:

1. Specimen box and specimen clamping device

2. Residential and re-exercise and scrubbing head clamping device

3. Set the counting display device

How to use:

Remove the brush arm with the wiper head part from the instrument and bring it close to the wipeThe lock nut of the head and the compression ring in it are removed, and four layers of medical gauze with a size of about 15mm are cut and wrapped in the wiping of the head, and then fixed with the compression ring and the lock nut.

The test will be prepared in accordance with the provisions of 63.1 of the GB17748-1999 standardThe sample is placed in the sample box and clamped, and the sample must not be strung during work

Attach the brush arm to the instrument and tighten it with a pur nut, wiping the head at this pointThe parts should move up and down freely in the brush arm, and the weight of the wiping head parts should be completely reducedon the specimen

Unscrew the knurled nut on the upper part of the wiping head part and pour the test solvent (outside).The test solvent of wall aluminum-plastic panel is butanone, and the test solvent of interior wall aluminum-plastic panel is dimethylbenzene, the test solvent of other substrates is determined according to the requirements of the standard). Adjust the knot doorThe gauze on the wiping head absorbs the solvent and can keep the gauze during the testInfiltration.

Turn on the power supply, turn on the power switch, and set the erasing time according to the standard requirementsnumber, press the number switch, make the count display the set value, and then press the start switch,The instrument will start to work, (if there is a value display after turning on the power, please press Reply.)Bit switch) counts to show that the instrument starts working, and when it reaches the set value, the instrument stops automaticallywork, if you need to stop halfway, press the pause switch to stop

Press the reset switch to remove the brush arm and the wiping head part and take it outSpecimens, visually inspect the scrubbing site for the phenomenon of revealing the inner layer (i.e., whether there is an exposed bottom).The test result was the worst of the three specimens

QFR

QFR