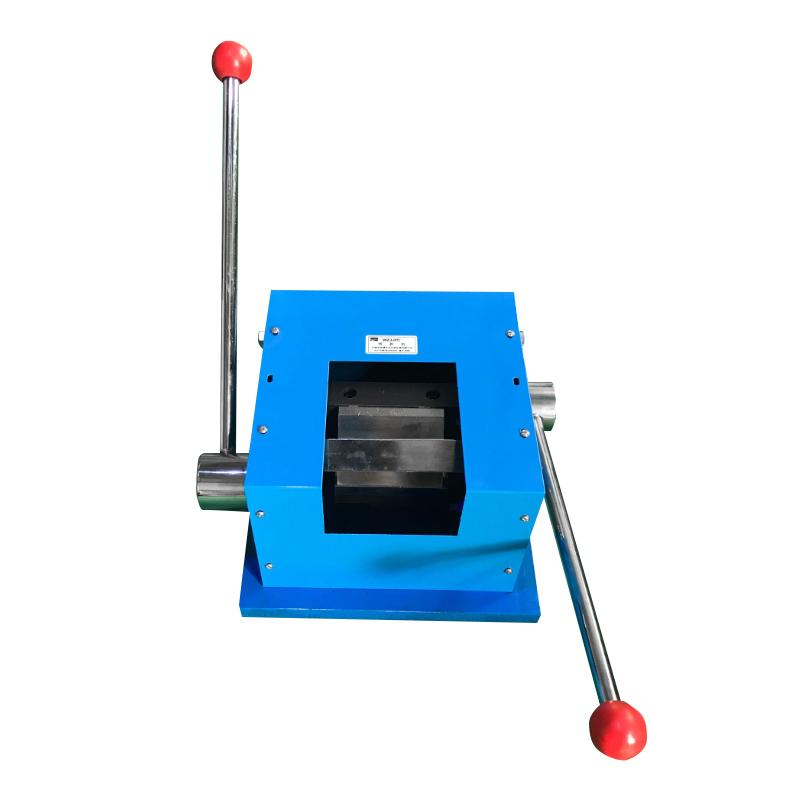

HuiNuo WZJ-II T-Bending Tester coating T-Bending machine, bending machine

HuiNuo WZJ-II Bending machineSPEC

HuiNuo WZJ-II Bending machineDetails

HuiNuo WZJ-II Bending machinePacking list

- SKU

- NB048518

- primary bend angle

- <45°

- Flattening mechanism travel

- ≥10mm

- plate thickness

- 0.5~ 1.0Mm (Steel, Aluminum Panel), soft substrate up to 2mm

Scope of application

The flexibility of the coating film is one of the important indicators to measure the coating, and it has great reference value for the screening and application of new product coating formulations.

The WZJ-II bending machine designed and manufactured according to the national standard GB/T12754 is a new model for testing the flexibility of coatings, which is suitable for testing the T-bending Tester of the coating of colored steel plates and steel strips, as well as the T-shaped bending Tester for the coating of related products.

Operating Principle

Through the rotation of the left handle, the square bending briquetting bending piece is paralleled into the shape of < 45 ° angle: the right handle is rotated to drive the crank lifting mechanism, so that the triangle bends quickly up or down, and the test piece is clamped or flattened to form a T-shaped bend.

Main structure

1. Bottom plate and left and right side plates.

2. Gear pair and crank lifting mechanism.

3. The triangle bends quickly.

4. Square rotation and dismantling block.

5. It is composed of a guard plate and a handle.

Use the procedure to do so

1. Specification: 400×100 (mm)

2. The sample piece should be placed in the environment of 23+2 °C for at least 24 hours before cutting, and the test should also be carried out under the same conditions.

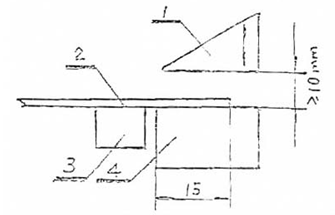

3. Rotate the right handle to pick up the triangular bending flattening block in the middle of the testing machine (≥10mm): rotate the left handle at the same time to make the square rotating dismantling block and the triangular bending flattening block line up with the bottom surface in a straight state. (as shown in the image)

(1) The triangle is bent and flattened quickly

(2) Trial sample

(3) Square rotation and disassembly block

(4) Bottom plane

4. The side of the test sample is facing down and stretching into the triangle bending and flattening fast 15mm, and the right handle is rotated to make the triangle bending and flattening block fall, and the test plate is compressed: the left handle is rotated to make the square rotate and disassemble and bend the experimental plate, at this time, the experimental plate forms an angle of < 45°.

5. Rotate the left handle to make the square rotate and disassemble the block back to its original position: rotate the right handle to make the triangle bend and flatten the block up, and take out the test sample.

6. The test class that forms an angle of < 45 ° is stretched into the triangular bending flattening block: rotate the right handle to make the triangular bending flattening block fall, and the angular end of the test board is compacted at this time, forming a head for the arc of thickness and two parallel faces. That is, complete the "OT" bending.

7. Repeat the above test operation steps, compress the bending part of the test plate "OT" test and bend and flatten, so that there is an intermediate layer of test plate thickness at the bending. That is, the "IT" test was completed.

8. Repeat the above experimental steps in turn, and you can obtain the bending of "2T, 3T" ....... (as shown in the figure)

Judgment of experimental results

Use transparent tape (≥0.25N/mm) to adhere to the curved surface of the test, flatten the tape with your fingers, and then tear it off immediately in the vertical direction of the coating surface, and check whether the coating at the bend is peeled off or peeled off, so as to determine the flexibility of the coating.

Precautions for use

1. When the bending of the specimen lies in IT, there should be no obvious gap at the overlap of the bending surface, otherwise the test will be redone.

2. Coating damage within 10mm from the edge will not be considered.

3. In order to facilitate transportation, when the testing machine leaves the company, the two handles are not installed on the main machine. After the user unpacks, install the two handles on the corresponding position of the host by himself.

WZJ-II

WZJ-II