HuiNuo QHQ Pencil Hardness Tester load 500/750/1000g

HuiNuo QHQ Pencil Hardness TesterSPEC

HuiNuo QHQ Pencil Hardness TesterDetails

HuiNuo QHQ Pencil Hardness TesterPacking list

- SKU

- NB048527

- load

- 500/750/1000g

- Applicable standard

- GB/T 6739-1996

- Substrate specifications

- 120*50*(0.2~0.3)mm

- material

- tinplate

- Standard pencil

- 6B-6H (13 pcs)

- test angle

- 45°

- size

- 430*160*280mm

- Operating temperature

- 23±2℃

- Relative Humidity

- 60~70%

1. Use

The hardness of the coating film is an important physical property of the coating film, and its size directly affects some important performance of the coating film, which is implemented according to the standard GB/T6739. For example, wear resistance, wear grain resistance, scratch resistance, impact resistance, as well as the retention effect of the coating film and the difficulty of cleaning, etc., therefore, the hardness of the coating film is a necessary index to evaluate the performance of the coating. This instrument can be used to easily determine the hardness of the coating film.

Second, the structure and working principle of the instrument

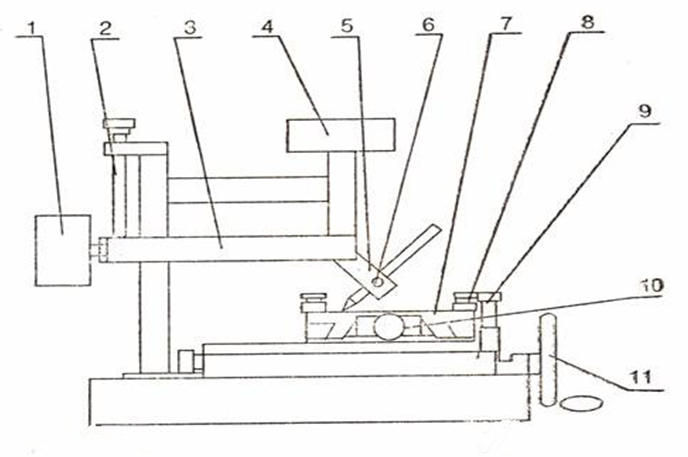

A structure(See attached photo)

(1) Counterweight (2) Stop screw (3) Working rod (4) Weight (5) Pencil holder (6) Screw (7) Test bench (8) Clamp nut (9) Brake tile twist (10) Twist (11) Hand wheel

B Operating Principle

This instrument is mainly composed of a pencil holder and a test bench, and the pencil holder and the column are set of four-link mechanisms to ensure that the weight of the weight acts vertically on the intersection of the pencil lead and the test bench, and keeps the pencil and the test bench at 45 °, and the angle remains unchanged. The test bench can be moved to and longitudinally, and the paint sample can be fixed with it, and the sample will move in the direction of the scratch, and the box than the pencil will draw the corresponding trajectory on the test piece. Different pencils are used to draw different marks, and the hardness value of the coating film can be determined.

3. Requirements for use

1. Test piece: smooth tinplate, 120*50*(0.2~0.3)mm, product specified substrate 120*50mm

2. Test environment: temperature 23°C±2°C Relative Humidity 60%~70%

Fourth, the operation and use of the method

A prepares

1. Prepare 120*50*(0.2-0.3) smooth tinplate or substrate according to the requirements of GB1727 to prepare a coating film.

2. Use a pencil sharpener to carefully cut off the wooden part of the front end of each pencil to expose a 5-6 mm cylindrical lead core (but do not loosen the lead core into a cut lead core), hold the pencil with your hand, so that the pencil is always at a 90° angle with the 400 sandpaper, and rub the end face of the lead core on the sandpaper until you get a pen end with a smooth edge and a sharp edge. (The edges should be free of chips or chips).

3. Insert the repaired pencil into the pencil holder (5) (see attached picture). Adjust the pencil so that the working end face of the pencil lead coincides with the center of gravity of the weight (the distance between the working end face of the corresponding lead core and the pencil holder is about 25mm), and then tighten it with a screw (6) to fix the position of the pencil.

4. Loosen the clamping nut (8), put in the coating film specimen to be measured, and then tighten the clamping nut to fix the specimen.

5. Loosen the stop screw (2) and adjust the balance hammer to balance the working rod. (even if the pencil is just touching the specimen), then tighten the stop screws so that the working surface of the pencil lead is away from the coated specimen.

6. Gently place the weight on the pencil holder.

At this point, the preparations are complete.

B test

1. Loosen the stop screw (2) and gently lower the pencil lead onto the test film test piece.

2. Turn the handwheel to move the coating plate about 5mm in the direction of the scratch (turn the handwheel clockwise) and pay attention to whether the surface of the coating film is scratched.

3. Remove the weight, replace the pencil, rotate the knob (10) of the test bench, make the test bench move longitudinally for a certain distance to replace the scratch position of the test piece, repeat the preparation operation, and then do the next test, and use the pencil of each type of hardness to plow out five scratches at a time.

4. Start with the hardest pencil with this method, when the five traces are verified, if there are more than two plow wounds, replace the pencil with a first-level pencil, until you find out that among the five traces, there is only one plow wound coated pencil (or no damage). The hardness value of this grade pencil represents the hardness of the tested coating film.

5. Maintenance

1. This instrument strives to rotate flexibly when using, and after a period of use, oil must be injected into the rotating departments such as lead screws and bearings.

2. After using this instrument for a period of time, tighten the screws, and the nuts need to be tightened to avoid loosening.

QHQ

QHQ