HuiNuo QYG film Freshness Tester distinctness of image

HuiNuo QYG Film Freshness TesterSPEC

HuiNuo QYG Film Freshness TesterDetails

HuiNuo QYG Film Freshness TesterPacking list

- SKU

- NB048564

- Measurement range

- 0~199.9GS (Gloss unit)

- Stability

- Less than +/- 0.4GS/30min

- error of indication

- Less than +/- 1.5GS

- Zero error

- With automatic zero stabilization function, no correction required

- Power Supply

- Four LRI batteries, Operating Voltage 3.8v-4.8v

- projection angle

- 20º60º85º

- Light spot size

- 20º:10*10mm;60º:10*20mm;85º:10*24mm

- Measurement port size

- 11*54mm

- conditions of use

- Environmental temperature: 0 ℃ -40 ℃, Relative Humidity does not exceed 85%

- Host size

- 140*45*85mm

- Host Weight

- 350g

The QYG Coating Film Reflective Gloss Tester is a newly developed compact portable machine. Its technical parameters are fully in line with the national standard GB9754, the international standard ISO2813, and the performance indicators have met the requirements of the national metrology verification regulations JJG696-2002 first-class working machine. This product is suitable for measuring the gloss of paints, coatings, inks, stones, paper, enamels, ceramic tiles and other flat products.

use

The decorative performance of the coating film is a comprehensive index, which is related to the smoothness, gloss and fullness of the coating film, and the index that characterizes this technical performance is the freshness.

QYG coating film afresh reflectance meter is a satisfactory instrument for measuring the decorative performance of the coating film, which can evaluate the coating film, especially the coating film on the surface of the car, and measure the freshness grade data simply and intuitively.

The main structure and working principle

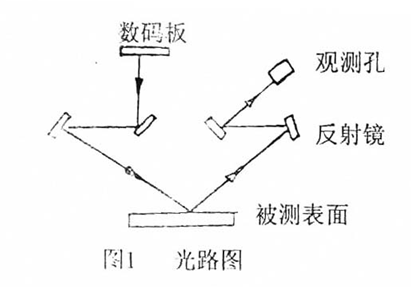

QYG coating film reflector is a portable instrument combining photoelectric and photoelectric combination, and its principle is to reflect the digital on the digital board through the irradiation of light and the reflection of the measured surface in the observation hole. Through the naked eye observation of the surveyor, the DOI value of the freshness level is read to achieve the purpose of measuring the decorative performance index of the coating surface, and the higher the DOI value, the better the freshness.

The instrument is composed of several parts: shell, imaging chamber, optical path, eyepiece and panel.

Operation and how to use

1. Open the cover and install the battery or plug in the external power supply.

2. Press the power switch, then observe the voltmeter, turn the Voltage adjustment knob, so that the pointer is in the 4.4V position, and the brightness meets the requirements. If the pointer cannot be adjusted to 4.4V after using a dry battery adjustment, the battery should be replaced.

3. Put the standard reflector on the table, align the measurement window at the bottom of the instrument with the standard reflector, then press the power switch, observe the digital plate reflected on the standard reflector from the eyepiece tube, and confirm that the DOI value of 1.0 on the digital board can be clearly read.

4. Place the instrument on the surface of the measured object, make the measurement window and the measured face align, press the power switch, observe the reflected digital from the eyepiece tube, and read the DOI value number clearly.

5. Repeat the measurement 5 times to take the average value as the result.

Note: The person who measured should be someone who can clearly read the DOI value of 1.0 on the reflector.

QYG

QYG