CHINA brand NBC-100L-70 programmable constant temperature and humidity testing machine

SE

Factory NBC-100L-70 Programmable constant temperature and humidity TesterSPEC

Factory NBC-100L-70 Programmable constant temperature and humidity TesterDetails

Factory NBC-100L-70 Programmable constant temperature and humidity TesterPacking list

- SKU

- NB048588

- A Temperature range

- -70℃ ~ +150℃

- Humidity range

- 20% RH ~98% RH

- control stability

- Temperature +/- 0.5-1 ℃ Humidity +/- 1-2%

- distribution uniformity

- Temperature +/- 1.5-2 ℃ Humidity +/- 1-3.0%

- Heating rate

- 3 ℃/min nonlinear no-load

- Cooling rate

- 1 ℃/min nonlinear no-load

- temperature limit

- Maximum temperature + 150 ℃ Minimum temperature -70 ℃

- Inner box size

- Width × Depth × Height W * D * H: 500 * 400 * 550 (mm)

- Outer box size (approx.)

- Width × Depth × Height W * D * H: 1020 * 950 * 1420 (mm)

- Total Weight (approx.)

- 170KG

- Electricity requirements

- Operating Voltage: 220V/50HZ. Voltage variation charging value : +/- 10%. Maximum Power: 6kw

- Inner box material

- Mirror stainless steel plate (SUS #304)

- Enclosure Material

- Mirror stainless steel plate (SUS #304)

The high-low temperature damp-heat alternating Test Chamber is mainly used to test the performance of materials in various environments and to test the heat resistance, cold resistance, dry resistance and humidity resistance of various materials. It is suitable for testing the quality of electronics, electrical appliances, communications, instruments, vehicles, plastic products, metals, food, chemicals, building materials, medical treatment, aerospace and other products.

Control mode: Balanced temperature and humidity control system (BTHC) is adopted, the induction system transmits the actual data in the Test Chamber to the controller, and the controller balances the output power of the temperature and humidity system through the control SSR and multi-segment intelligent output, so as to ensure that the temperature and humidity in the Test Chamber are fully stable, and has the function of energy saving, which greatly reduces the power of the instrument and ensures the long-term accurate and stable operation of the instrument.

Features

1. The product has beautiful appearance, reasonable structure, precise process, simple and convenient operation and stable and reliable performance.

2. The controller adopts a large color LCD human-machine touch dialogue LCD human-machine interface controller, which is simple to operate, easy to learn, stable and reliable, and displays the complete system operation status, execution and setting program curve in Chinese and English, and can realize RS232 computer interface docking.

Control the instrument remotely directly from your computer.

3. Compressor is used in the refrigeration circulation system: the original imported Japanese "Sanyo" brand fully enclosed compressor (purchased by Taikang compressor in France), all components are imported components, respectively from Japan, France, the United States, Italy and other origins, and the refrigerant adopts American environmentally friendly refrigerant (R23A, R404A).

4. There is a test hole with a diameter of 50mm on the left side of the Test Chamber.

5. It has a fully automatic, high-precision system loop, any part action, P.L.C locking processing, and all P.I.D automatic

Calculated control, the temperature of the whole area has high precision and high stability.

6. Specially designed air circulation system and sensor system, the air outlet is detected and controlled by the return air outlet sensor, so as to ensure the uniformity of temperature in the Test Chamber and avoid any dead ends.

7. Adopt enlarged observation window, 4 layers of air-filled tempered glass, and have a wider field of vision.

8. The instrument has a comprehensive protection system, power overload protection, leakage protection, control loop overload, short circuit protection, compressor protection, grounding protection, over-temperature protection, alarm sound prompt, etc., when any abnormal situation occurs, the screen will automatically display the fault point and cause and automatically shut down.

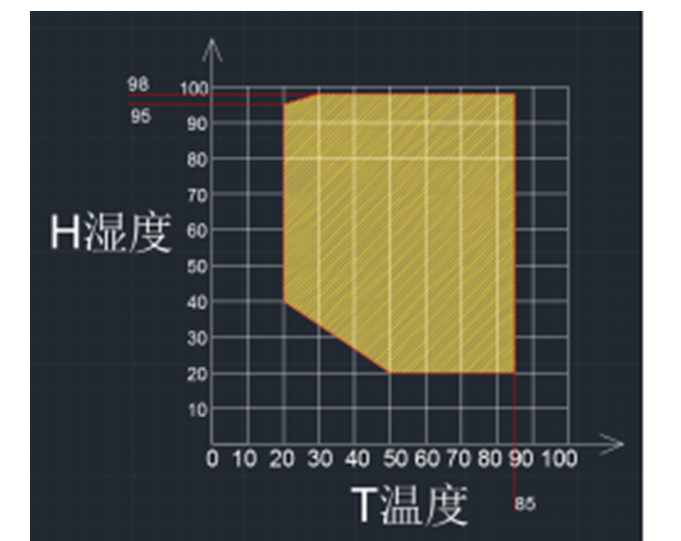

9. Temperature and humidity control range curve

- 1Application of Humidity Chamber in humidity resistance test of photovoltaic backplane adhesive

- 2Common faults and solutions of Humidity Chamber

- 3Correct operation steps of constant temperature and humidity Test Chamber [video explanation]

- 4Application of Constant Temperature and Humidity Test Chamber

- 5How is the Humidity Chamber used in the material humidity resistance test?

- 6Foam humidity resistance test

- 7Application of Humidity Chamber in humidity resistance test of hot-melt adhesive

- 8Application of Humidity Chamber in moisture and heat resistance of grease

- 9Application of Humidity Chamber in bearing moisture and heat resistance

- 10Application of Humidity Chamber in Moisture Heat Resistance of Plastic Powder

- 1IEC 《Environmental testing – Part 2-78: Tests – Test Cab: Damp heat, steady state》

- 2IEC 《Environmental testing – Part 2-67: Tests – Test Cy: Damp heat, steady state, accelerated test primarily intended for components》

- 3ASTM 《Standard Practice for Heat and Humidity Aging of Oxidatively Degradable Plastics》

- 4GB/T 42125.4-2024《Safety requirements for electric equipment for measurement, control, and laboratory use—Part 4: Particular requirements for climatic and environmental testing and other temperature conditioning equipment》

NBC-100L-70

NBC-100L-70