HuiNuo TM1000/07 Film Applicator (reciprocating lame plating) polymer emulsion 160 * 80mm

HuiNuo TM1000/07 Film ApplicatorSPEC

HuiNuo TM1000/07 Film ApplicatorDetails

HuiNuo TM1000/07 Film ApplicatorPacking list

- SKU

- NB049118

Introduction

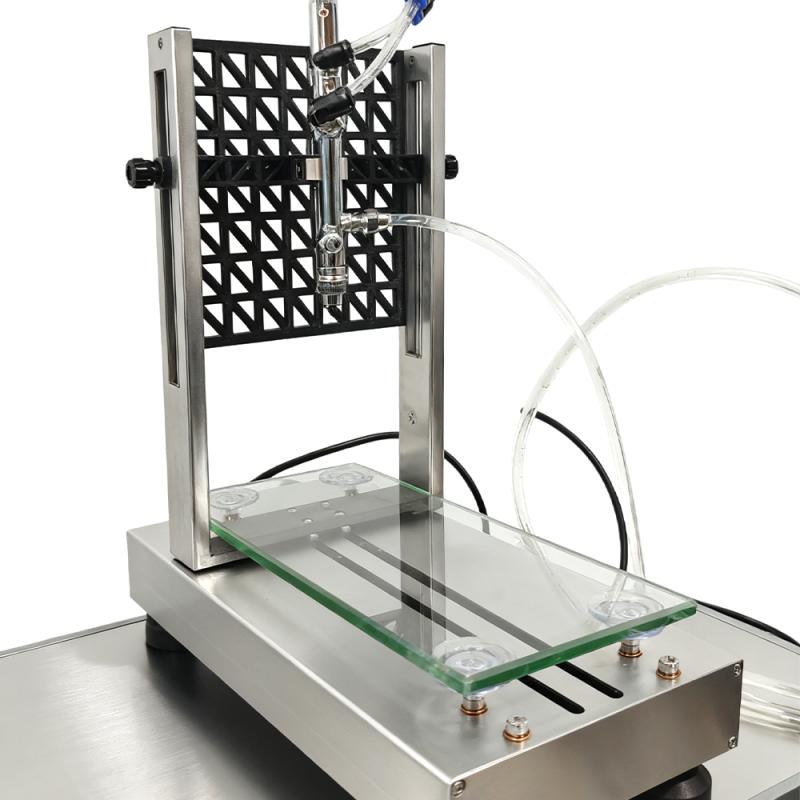

TM1000/07 Micro Flat Sheet Applicator (Reciprocating Spraying) with an effective area of 160×80mm (expandable to 200×100mm) in a compact body size of about A4 paper for a standard ventilation kitchen. It is powerful, can be sprayed accurately on a small area, and supports multiple cycles; With programmable control, spraying speed, discharge volume, drying and pause time can be adjusted, and vacuum adsorption fixes the substrate to ensure smooth spraying. The motion, spraying, and control systems work together, and the PLC and touch screen realize parameter presetting and real-time monitoring. A 7-inch touchscreen is embedded on the side for easy operation

Core features

Precise spraying on a small area (16×8cm) supports multiple spraying cycles.

Programmable Control:

The spraying speed and discharge amount can be adjusted

Drying time and pause time can be set freely (support second-level adjustment)

Vacuum adsorption fixes the substrate to ensure a smooth spraying.

Subsystem composition

Motion system – a rodless cylinder pushes the gun to reciprocate (manually adjusts the movement speed).

Spraying system - precision piston pump + pneumatic atomizing Spray Gun (support flow/pressure adjustment).

Control system - PLC + touch screen, support parameter preset and real-time monitoring.

Structural layout

Overall dimensions

Length × width × height: 300mm× 240mm×200mm (about the size of A4 paper, can be put in.)

standard ventilated kitchens; This height does not include the gun mount, which is about 400mm).

Space allocation

Upper layer: Gun moving guide (covers 16×8cm spray area).

Middle layer: substrate adsorption platform (with vacuum interface).

Lower layer: control box + pump body + solenoid valve.

Interactive

A 7-inch touchscreen is embedded on the side for easy parameter setting and monitoring.

TM1000/07

TM1000/07