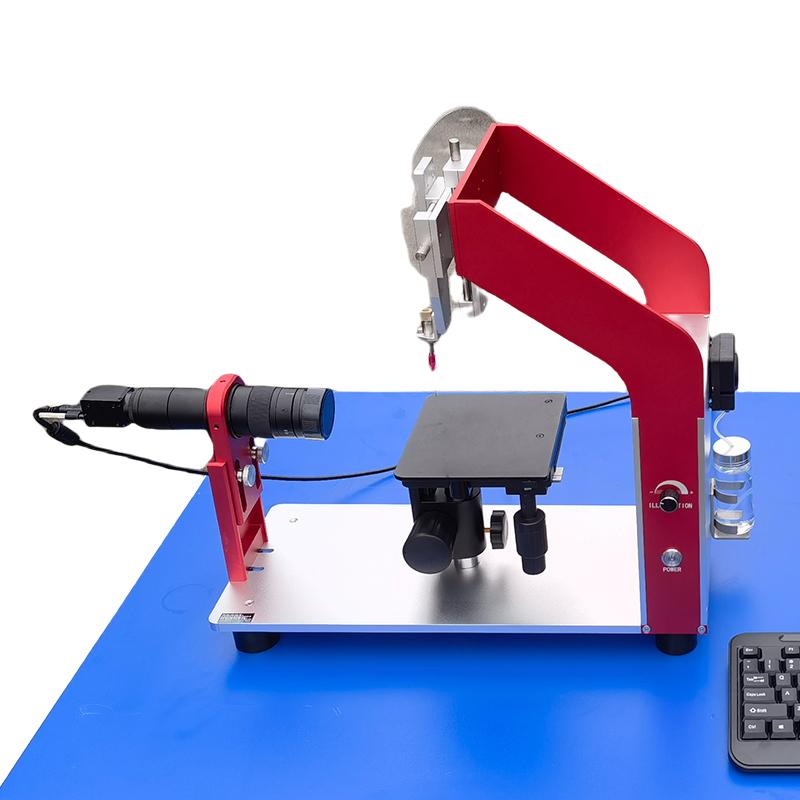

LX-100B Contact Angle Meter surface contact angle wetting performance table interfacial tension surface energy

Factory LX-100B Contact Angle MeterSPEC

Factory LX-100B Contact Angle MeterDetails

Factory LX-100B Contact Angle MeterPacking list

- SKU

- NB049274

- Measurement range of contact angle

- 0~180°

- Measurement Accuracy of contact angle

- ±0.1°

- syringe

- Special precision syringe, Capacity 500μL

- Dripping method

- Manual swirl/spin feed, drop Accuracy up to 0.1 μL

- Injection unit movement

- Up and down 100mm; left and right 100mm

- Table size

- 130mm*150mm

- Maximum sample size

- He is a size six.

- Sample stage movement

- Move back and forth, manual, stroke 60mm, Accuracy 0.1mm move around, manual, stroke 35mm, Accuracy 0.1mm move up and down, manual, stroke 80mm, Accuracy 0.1mm

- Dimension

- 550*196*485mm

- Weight

- 11KG

- Power supply Voltage

- 220V/60HZ

- Light source

- Dense LED Adjustable Blue Color Industrial Cold Light source

- lifespan

- The service life is more than 25,000 hours

- Dynamic contact angle fitting

- Batch screenshot fitting, video continuous automatic fitting, automatic online real-time fitting

- Table/interfacial tension test

- Hanging drop method (real-time fully automatic dynamic surface tension test)

- Test droplet status

- Pendant Drop, Sessile Drop (2/3 state), Bubble Capture, Seat Drop, Seat Needle

- CCD camera

- SONY original imported high-speed industrial-grade chip, 25 frames/S, 130W pixels

- lens

- 0.7-4 High Definition Industrial Continuous Zoom Microscope

- Acquisition system adjustment

- Front and rear 60mm, adjustable Viewing Angle (head-up, 360 ° swirl/spin and other multi-Viewing Angle)

Introduction

Contact angle refers to the tangent line of the gas-liquid interface made at the intersection of gas, liquid and solid, and the tangent angle θ between the tangent line and the solid-liquid junction line on the liquid side, and the contact angle measurement is the main method of surface performance testing today.

The standard contact angle measuring instrument is based on the principle of optical imaging, which measures the surface contact angle, wetting performance, surface tension, surface energy and other properties of the sample surface through image profile analysis.

apply

Contact angle measuring instrument is widely used in various industries, in mobile phone manufacturing, glass manufacturing, surface treatment, material research, chemical industry, semiconductor manufacturing, paint and ink, electronic circuits, textile fibers, medical biology and other fields, contact angle measurement has become an important instrument to evaluate surface properties. (Some test functions need to be completed by purchasing special accessories)

1. The wetting behavior of the liquid on the solid surface, such as spreading, penetration, and absorption, is measured by the droplet method

2. Measurement of the advance angle, backward angle, contact angle hysteresis, rolling angle and dynamic contact angle of the material on the solid surface

3. Continuous real-time research and process recording of absorbing materials, and analysis of contact angle curves with time

4. Contact angle measurement of various special materials, such as powders, curved surfaces, superhydrophobic/superhydrophilic samples

5. Attachment drop method test: Contact angle test of material immersed in liquid

6. The hanging drop method measures the surface interfacial tension and polarity and dispersion components of various liquids

7. Calculation of surface free energy of solids, and analysis of polar dispersion components

8. Analyze the adhesion of liquid on solid surface, evaluate the uniformity and cleanliness of solid surface

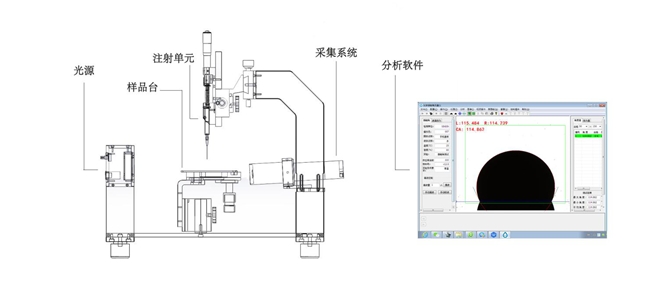

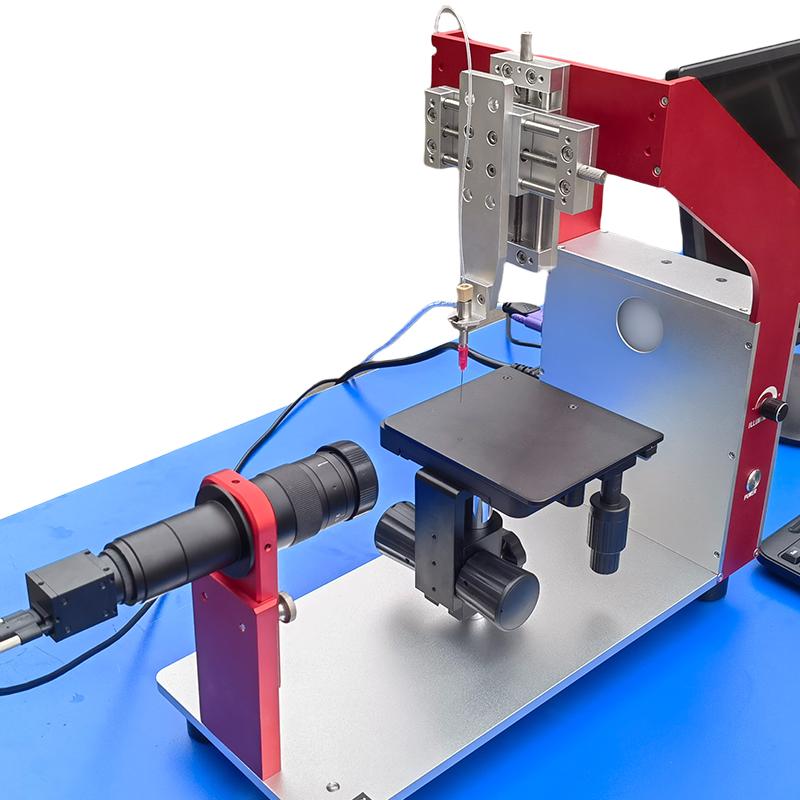

Principle of the device

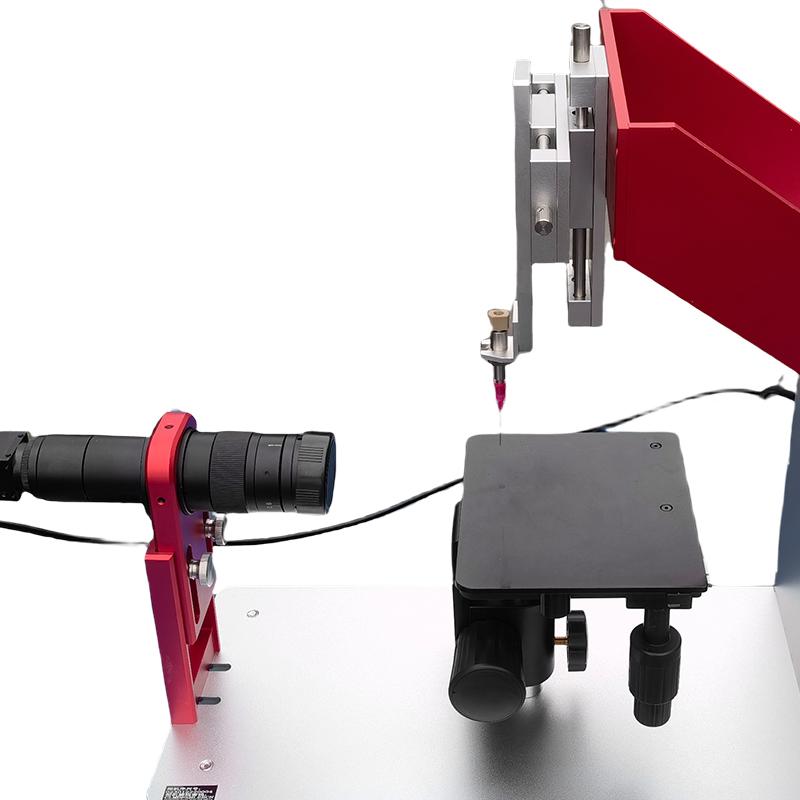

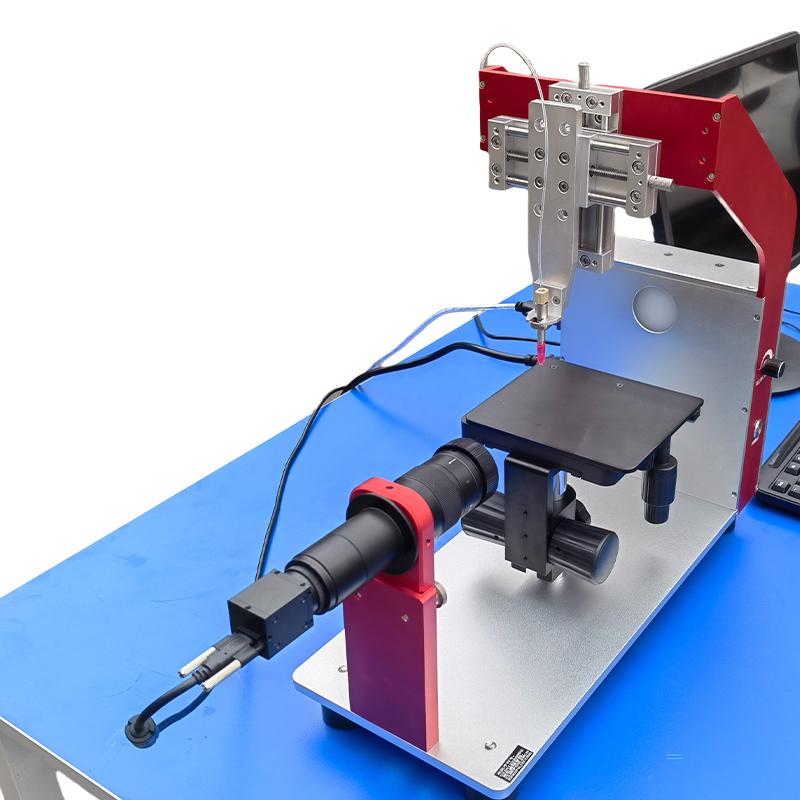

As shown in the figure above, the contact angle measuring instrument is mainly composed of five parts: light source, injection unit, sample stage, acquisition system and analysis software, and the equipment adopts the principle of optical imaging

The light source adopts dense LED cold light design, which emits uniform light, image cleaning and long life

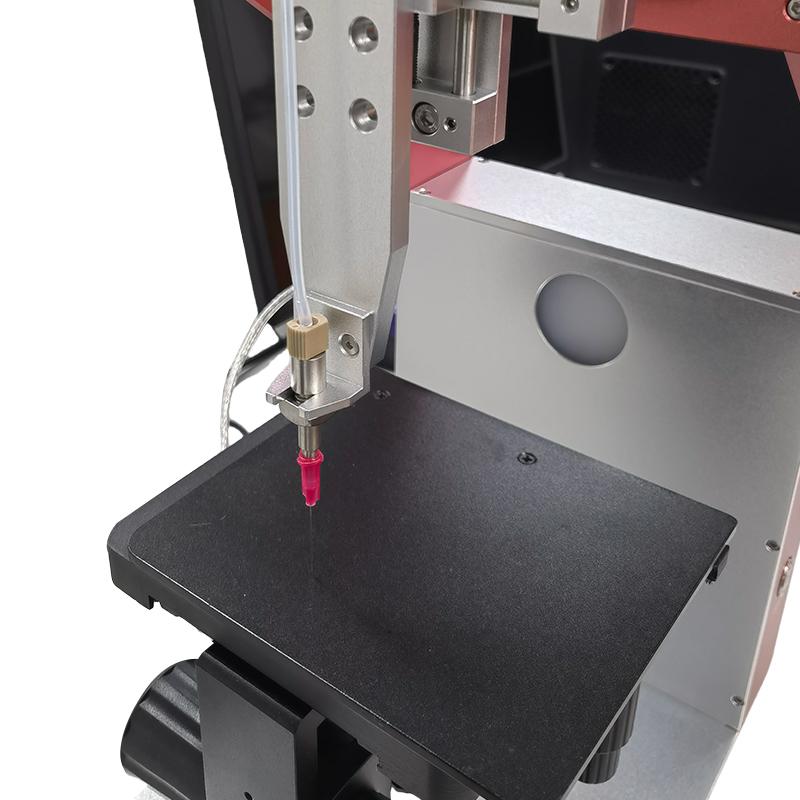

The injection unit adopts a micro-manual knob type liquid feeding, which is stable and has high precision

The sample stage adopts a three-dimensional manual fine adjustment platform, which is flexible in operation and accurate in positioning, and the sample stage can be customized according to the actual sample size

The acquisition system adopts black and white imported CCD camera, shooting stability, clear image, real and reliable, the lens adopts German industrial-grade imported configuration, 0.7-4.5 times magnification adjustable, and the imaging is deformed without deformation

The analysis software is powerful, with one-click automatic fitting ability, and has international advanced fitting methods to meet the accurate fitting of various drop morphologies

Comply with relevant national standards

GB/T 24368-2009 (Detection of hydrophobic contaminants on glass surface)

SY/T5153-2007 (Method for determining the wettability of reservoir rocks)

ASTM D 724-99(2003) (Test Method for Surface Wettability of Paper)

ASTM D5946-2004 (Measurement of Contact Angle of Plastic Film with Water)

ISO15989 (Measurement of water contact angle of plastic film and sheet corona treatment film)

LX-100B

LX-100B