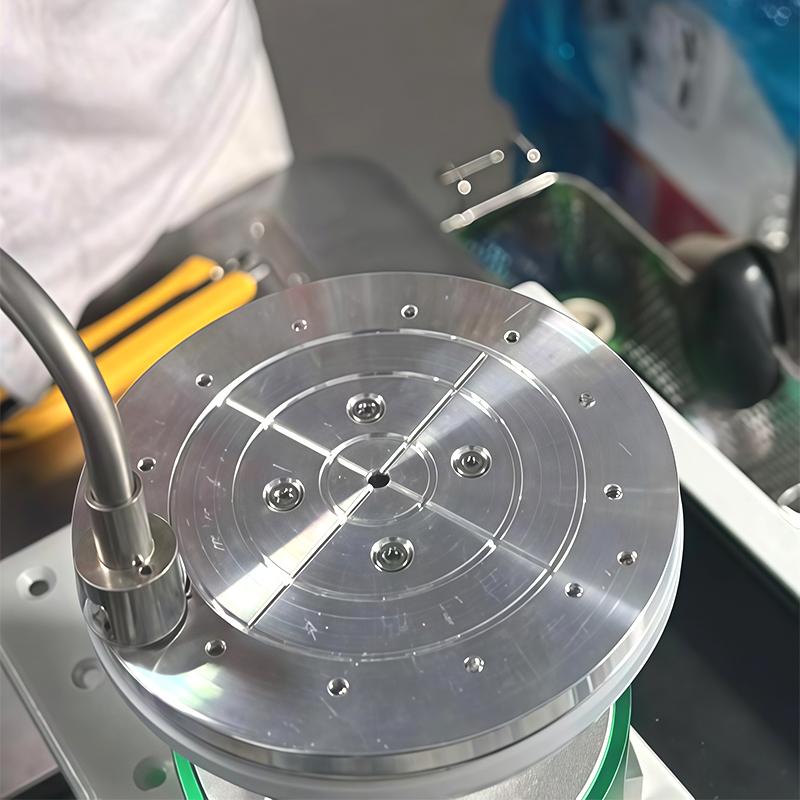

HuiNuo NBC-12TV2 (180 ℃) heating type uniform glue Spinning Coater Spinning Coater

SEHuiNuo NBC-12TV2(180℃) Heated Spinning CoaterSPEC

HuiNuo NBC-12TV2(180℃) Heated Spinning CoaterDetails

HuiNuo NBC-12TV2(180℃) Heated Spinning CoaterPacking list

- SKU

- NB049294

- Heating method

- The temperature is directly controlled by the chip holder itself, and the heat exchange speed between the silicon wafer and the chip holder is about 1-3 seconds

- Temperature control mode

- Temperature control, the suction cup is directly and quickly raised to the process temperature

- Heating time control

- 1-9999 seconds or 1-9999 minutes

- Heating part

- Film holder, suction cup, temperature control heating

- heating temperature

- Room temperature~ RT + 180 ℃

- Rotational torque

- 100Rpm torque greater than 1N.m speed stability

- rotational speed

- 100-3000rpm, acceleration 100-3000 rpm, 5 speeds, 12 sets of parameter memory

- Suction cup

- Customized, suitable for item size No. 5-100.

- power

- 600W

- Voltage

- 220V

- Host Dimensions

- Length 400mm × Width 250mm × Height 350mm

Introduction

NBC-12TV2 (180°C) Heated Homogenizer is an advanced equipment designed for high-precision gluing process. It adopts the direct temperature control technology of the sheet tray, the heat exchange speed is as fast as 1-3 seconds, and with the customized suction cup, it can be adapted to the size 5 to 100 items, ensuring a stable and efficient gluing process. Its speed range is 100-3000rpm, acceleration is 100-3000 rpm, with 5 speed adjustments and 12 groups of parameter memory functions, which can meet the diversified process needs. At the same time, the heating time of the equipment can be accurately controlled, and the main machine is compact in size, with a size of 400mm×250mm×350mm, which is suitable for a variety of working scenarios. The uniform machine adopts 220V Voltage and 600W power, which is stable and safe in operation, and is suitable for semiconductors, microelectronics, optical films and other fields, helping users achieve high-quality gluing effects and improve production efficiency and product performance.

Heating component operation process

1. The heating component of the backpack at the back of the homogenizer, the power switch - press, and observe the instrument power-on and display;

2. The timer is not running, RST button - press once, observe the timer - start the countdown;

3. For example, set the temperature of the thermostat of the component to 100 degrees Celsius, observe the display value of the thermostat, observe the flashing of the blue heating indicator, which will be stable for about 1-3 minutes (plus or minus 1 degree Celsius), and detect the surface temperature of the sheet tray in combination with the contact thermometer (pay attention to the contact temperature measurement error);

4. For example, silicon wafers with a diameter of 20mm and a thickness of 1mm should be placed on the tray and heat exchanged for about 1-3 seconds;

5. Combined with the self-provided contact temperature measurement or far-infrared temperature Measurement Instrument to obtain the actual temperature of the object, if it does not meet the expected temperature, the set temperature can be modified through the thermostat, and the temperature of the silicon wafer and other items can be corrected;

NBC-12TV2(180℃)

NBC-12TV2(180℃)